DIY Cruising Catamaran: Complete Building Guide

As an Amazon Associate, we earn from qualifying purchases. We may also earn commissions if you purchase products from other retailers after clicking on a link from our site.

A brand-new cruising catamaran can set you back a hefty amount of money. However, a DIY cruising catamaran provides a more affordable way to own your own boat. While building a large boat can be an extremely challenging and time-consuming experience, nothing beats the pleasure of bringing your own boat to life.

To build a DIY cruising catamaran, buy good design plans, determine your budget and find a working space. Next, choose your hull material, buy supplies and start building the mast beam. Build and sheathe the hull, install bulkheads, the interior, and finally, launch the catamaran boat.

In this article, you will find a complete guide to building your own catamaran. You will also find detailed information on why you may want to consider building your catamaran and approximately how much this project would cost. Finally, we will explore the advantages and disadvantages of building a catamaran from scratch.

Why You Might Want To Build Your Own Catamaran

Most people might think that purchasing a used boat to repair and fix it up would be cheaper than a DIY cruising catamaran. But while building your own catamaran could be an enormous undertaking, it also comes with many advantages over buying something used.

Other than the unique opportunity to create beautiful memories and experiences while cruising, sailing, and exploring beautiful coastlines, there are a number of benefits that come along with the DIY approach.

Knowing Your Boat

Building your own catamaran provides you with intimate knowledge of your boat. You will know every corner, including where to find every bolt, wire, bulkhead, rib, hose, and support as you installed them yourself. This knowledge will enhance your confidence while at sea since you will have entrusted your life to a boat whose history you are aware of and deeply connected to.

Pride of Ownership

The satisfaction you get from crafting something with your own hands is immense. As a result, the knowledge that you built your boat from scratch will fill you with absolute pride and an immense sense of achievement. Furthermore, as an owner-builder, you get to keep and enjoy the boat for as many years as you wish.

Substantial Cost Savings

Building your catamaran will work out cheaper than buying a new or even gently used boat. Though you will likely require some additional labor since doing some things will require an extra pair of hands, if you are particularly good at DIY, you will save a significant amount of money on labor costs as a whole.

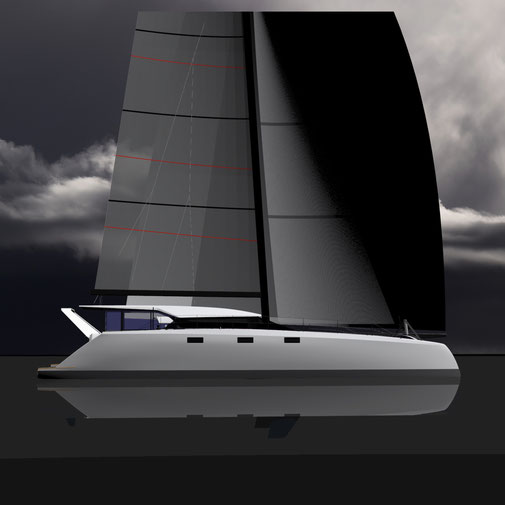

Freedom To Create Your Own Designs

If you decide to buy a catamaran boat, it might not be easy to find one that meets your unique needs. However, instead of choosing from production boats that bear traditional and outdated designs, you can come up with an ultra-modern design or style for your catamaran. You also get to pick your layout, size, and equipment based on your taste and budget.

Great Learning Experience

Building your own boat will help you pick up numerous skills that will come in handy later when sailing your boat. As much as you might still require an expert to help you with specialized skills like carpentry or wiring, your new skills will serve you well. This will also be beneficial when it comes to your boat’s maintenance and fixing things for yourself.

What To Look For in Catamaran Boat Designs

When deciding on the type of catamaran boat to build, you may want to choose a design that’s simple and easy to build. This is because doing so will allow you to spend a shorter time building the boat.

You also need to have a set of requirements to guide you in choosing your design or what you might call an ideal cruising catamaran wish list. This is essential because, ultimately, you want to build a boat that offers outstanding qualities such as:

- Delivers good speed

- Affordable to own and operate

- Agile, strong, and easy to maintain

- Has a high resistance to capsizing

- Great for sailing and cruising

- Delivers a comfortable and easy motion underway

- Good handling ability and high performance under sail

- User-friendly embarking and disembarking

- Provides ample living and accommodation space

- Presents a reasonable resale value

It’s worth noting that, in general, catamaran boats tend to offer a fair resale value mainly because of scarcity and the high price accorded to production models. So, if you build a well-constructed catamaran, you are bound to get a return that’s much higher than the cost of materials upon resale.

It’s also good to consider whether the design you settle on is from an established designer. This is significant because documentation of the building process is just as valuable when it comes to selling the boat.

How Much Would It Cost To Build Your Own Catamaran?

The cost of building your cruising catamaran will depend heavily on the size of the boat you plan to build and the skills you bring to the table. To give you an idea of probable costs, a professionally built 40 foot (12.1 m) long cruising catamaran could go for up to $300,000.

Though building it yourself will undoubtedly be cheaper, most DIY boatbuilders tend to underestimate the expected costs. Your final costs should cover not only the cost of material and equipment but also the labor and time it would take to come up with the final product.

If you were to build a 40-foot (12.1-meter) catamaran, your cost of materials would range between 20-30% of the total cost. Therefore, for $300,000 total, the boat’s materials would range between $60,000 and $90,000. The hull tends to range between 15-35% of the total build. Again, this depends on the finish and furniture.

But before you even start working on the DIY project, you will need to figure out where to do the work. If your home has ample space, then you can opt for a backyard building. But if you live in a small apartment, then you might want to consider renting a small garage at first and then move on to a boatyard later. This is one of the significant costs involved in building your multi-haul.

What You Will Need

To get a clearer picture of how much the entire project would cost, let’s have a look at what else you will need to purchase.

- Good design plans

- Working space

- Ground tackle

- Matting and roving

- Equipment such as the engine, windows, rudders, deck fittings, mast, and rigging

In addition to the above, you also need to install plumbing and electricals. You may also want to consider going electric rather than using diesel. Not only will this drastically reduce your maintenance costs, but you get to use the regenerated power for all of your housing needs while sailing.

Some catamaran boat designs help you save costs by advocating the use of less expensive corpus materials. Most of the material goes directly into making the boat, which means there is hardly any wastage on vacuum bagging . With this method, there are few molds and temporal building forms and fewer fillers to grind off as waste. All these factors reduce the time and cost it takes to build your catamaran boat.

That said, building a boat of any kind is a huge financial undertaking. As such, you still need to have the financial ability to keep building; otherwise, your project will stall or take much longer than anticipated. Instead of enjoying yourself and making memories cruising to faraway lands, you might end up spending all your time building a seemingly never-ending boat.

To reiterate, this project is more of a labor of love, given that it involves a tremendous amount of manual work. Calculating an hourly rate on the time spent building the boat and adding this cost to that of materials may make it seem a very pricey exercise. However, it is vital to understand that your time matters, and every hour you spend working for “free” should be included.

With that in mind, you need to ensure that you are fully devoted to the boat construction project and are sure you want to do it before you begin. Stopping halfway because it seems like too much work would be incredibly costly.

How To Build a Catamaran

When it comes to building a cruising catamaran, you have 3 main options:

- You can buy an old boat and refurbish it.

- Purchase a bare hull plus deck molding for a home-boat building.

- Start from scratch and build everything, including the hull, on your own.

As mentioned above, renovating an existing boat may end up being more costly than starting from scratch. To build a catamaran boat from scratch, follow the below step-by-step guide.

Prepare the Essentials

Before you jump into such a large project, there are several important aspects to consider:

- Buy your plans from an established catamaran designer. You can also get inexpensive, easy-to-build catamaran designs online.

- Get access to a large working space or build a shed . Depending on your climate, you may need to opt for climate control to avoid an excess of moisture in humid areas.

- Decide on your choice of hull material. This could be fiberglass, aluminum, steel, wood, or ferroconcrete.

- Start working on a bill of materials estimate. Include everything that you think you need to get a better idea of the initial costs.

Build the Mast Beam

Using wood and epoxy, cut and glue together the pieces of wood that will form the mast beam. Most of the work at this stage can occur in a garage since it involves building small parts. Still, the work could take up to 4 months, so be prepared to put in long hours.

Build the Boat Hull

Now, it’s time to build the boat’s hull. A catamaran comprises two hulls which are connected with a deck. Below is a short video showing how to build a hull mold:

This work requires a larger facility, so you might need to move out of the garage and into a boatyard. If you don’t have access to a larger workshop, consider building a shed where you can work as you do the construction. Make sure there’s enough room to fit the boat and also allow you to work comfortably. To cover the shed, you can use opaque white tarps.

Sheathe the Hull

Get all the materials you require for this stage in the construction, such as lots of resin, fiberglass, and foam for use in the hull cores. You’ll also require matting and glass roving to sheath the hull .

Sheathing helps to make the hull impervious to water and other marine borers. But first, you need to prepare the hull using a rotary sander. To make it as smooth as possible, use light, sweeping strokes. This is a very dusty task so be prepared to wear a facemask and safety goggles.

Install the Bulkheads

Next is installing the plywood bulkheads . You might need to call in friends to help turn the hulls or use a crane. In this step, you will need to laminate the hull sides on the molded hull panels and bond them above the bulkheads. Ensure the bulkheads are snug and sealed in place.

Construct the Interior Structure

Over the next couple of months, the boat work will involve joining the hulls together with the beams that you had made back in the garage. Then, install the cuddy cabin, decks , and the cockpit . Soon the boat will start to take the shape of a catamaran.

Next, proceed to construct the major structural components such as stairs, hatches, mini-keels, and the interior. Then comes the work of fairing the boat, which is quite labor-intensive.

Finally, it’s time to apply primer on the catamaran boat and start the paintwork. Before painting the boat, you will need to do additional sanding to finish off the two layers of primer as well as fill all the pinholes. Since it’s a large boat, the catamaran has lots of surface area; thus, the sanding could get extremely exhausting—mentally and physically—at this point.

The painting can take a while, too. The hulls are the easiest to paint, but the topsides, non-skid, as well as masking and prepping could seem never-ending.

The final stretch involves working on the center bridge deck cabin and other final touches like installing the engines, electricals, and plumbing. This is also the time to fix the rudders, rigging, mast, windows, and deck fittings.

Launch Your Cruising Catamaran

After many months or years of hard work, your cruising catamaran is finally ready to test the waters. After lowering the boat into the water, check carefully in case there are leaks. If none, you can set up the sails and take your catamaran out for your first cruise.

Below is a short video that takes you through the entire boat-building process:

If you don’t have deep pockets, don’t despair. It’s also possible to build an inexpensive catamaran boat, as shown in this post from the coastal passage .

The Pros of Building a Catamaran

Though it will be a costly endeavor, there are so many things to look forward to should you decide to build your own catamaran:

- It can be lots of fun.

- You get to have a new boat.

- It’s an excellent hobby for DIY enthusiasts.

- The effort is rewarding.

- It offers a great learning experience.

- You get the exact kind of boat you want.

- You can alter building plans and tailor the boat to suit your specific needs.

- It might be cheaper than buying a new boat.

The Cons of Building a Catamaran

Though there are a number of positive aspects to a DIY build, it is just as important to keep in mind that it won’t always be easy:

- Maintenance costs can be quite high.

- It’s both mentally and physically exhausting.

- It might require some technical know-how.

- It can take many months or even years to complete.

- It requires a lot of commitment to finish the DIY project.

- It might be challenging as well as expensive to get insurance.

- You will spend almost all your free time building the boat.

DIY Cruising Catamaran Tips and Tricks

If you are new to boat building, it would be a good idea to build a small boat first. This would give you a good indication as to whether you’d enjoy tackling a more extensive project like building a catamaran. Again, if you are the handy type, fixing your own electronics could also save you a significant amount of money.

Here are more tips and tricks to get the most out of your DIY cruising catamaran:

- Lower your costs. Bring down your costs even further by sourcing for parts and supplies at marine surplus outlets, Craigslist, eBay, or wholesale suppliers.

- Enhance your resale value. Most home-built boats are not easy to sell since they tend to be too customized. To enhance your resale value, it’s advisable to work with a standard design from a well-established naval architect.

- Follow the design instructions. Make sure to follow the designer’s instructions regarding the type of materials and tools to use during the build to avoid making costly mistakes.

- Maintain your original budget. Avoid any additional customizations once you have started building the boat. Using good plans and sticking to them ensures that your budget doesn’t spiral out of control.

Final Thoughts

Building a catamaran is about more than saving money. It’s fun, exciting, fulfilling, and can be a great learning experience. While it might take many months of back-breaking work, comparative shopping and sourcing for materials will help you save a lot of money. Still, at the end of it all, you’ll have a beautiful catamaran boat, all ready for your first cruising adventure.

However, if you have neither the time nor the energy to build your own catamaran from scratch, refurbishing an existing hull might prove faster and easier. It also works out much cheaper than buying a new boat.

Owner of CatamaranFreedom.com. A minimalist that has lived in a caravan in Sweden, 35ft Monohull in the Bahamas, and right now in his self-built Van. He just started the next adventure, to circumnavigate the world on a Catamaran!

One thought on “ DIY Cruising Catamaran: Complete Building Guide ”

Hello, I am a French Quebecer who is original, imaginative, creative and who finds that all boats and catamarans have a huge flaw and a very big lack of logic. I would have a brand new concept…. I am sending this message to any catamaran creator – designer to make those who have the opportunity and the intelligence to want to know about my innovative idea which will finally upset the market much richer. An idea that will totally change the concept of sailing, navigation and save so much worry!! All I would ask for is a small percentage of each sale of the new product. To be able to make me produce one when I have enough!! It is certain that like that, you just want to tell me: come on Mr. Lessard give us your idea but do not take your word to help me in return! But, if you are the kind of man to have only one word and maybe have a proof of your good faith if the realization of the project would make it… I will be very happy!! Giving it to everyone wouldn’t bother me either…. all I would like is to be able to find flax fiber (too expensive carbon) to be able to try to make my catamaran myself. Because not rich! Have a nice day and looking forward to having a message!!

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

Save my name and email in this browser for the next time I comment.

Recent Posts

Must-Have Boat Gear for Catamaran Sailors!

Sailing is probably the most gear-intensive activity I've ever done; there are so many decisions to be made about what gear to buy now, for tomorrow, and what to definitely never buy. The gear on...

6 Best Trailerable Trimarans For Bluewater and Coastal Sailing

Having a boat costs a lot of money, even when you are not using it, marina fees, etc. And once it is in the water most sailors never go very far from their "home marina" and sailing will be somewhat...

- FUSION THE SMART CHOICE

- BUILDING YOUR DREAM

- FUSION THE BOAT

- TESTIMONIALS

Construction Flexibilty:

By producing this modern catamaran in modules, which in turn fit in containers, it has meant delivery is simple and it has opened the doors to worldwide marketing of the Fusion 40. The cost savings on overseas shipping as deck cargo, is in excess of $40,000.00. Private contractors are available to assist with assemblies to any stage if you desire.

For more information on this fabulous product, or even where the closest one to you is, please click here to contact us .

- GRAINGER DESIGNS

CRUISING NEWS

The seafront of Cartagena in Colombia is the backdrop for two sailing vessels of different epochs and sharply contrasting character.

Against the sea wall Galeon Bucanero , a replica of a Spanish galleon of the seventeenth century is totally at home against the fortifications of this historically significant Spanish port city.

In the foreground Chincogan 52 Sole currently circumnavigating the globe stops over en route to Panama and the Society Islands.

Over the years I've received many wonderful photos of our boats from around the world. This one is an absolute classic. Many thanks to Mike and Sarah Mason for the shot.

THE WORK WE DO

RAKU CATAMARANS

CUSTOM DESIGN

SENSORI POWER CATAMARANS

SPLASH DOWN FOR RAKU 44#1

Raku 44#1 launched in Brazil. See more images in the build gallery here

Join the Newsletter

- Scroll to top

Matt & Jessica's Sailing Page

Experiencing the world while it's still large

What is it Going to COST to BUILD a Kit CATAMARAN? – A Comprehensive Guide (MJ Sailing)

The big question on everyone’s mind is … what is it going to COST us to build this new catamaran?

Matt has spent the past few weeks talking to the designers at Schionning and Oram, as well as professional and ameture builders to gather as much information as possible on the costs that go into building a kit catamaran. Things can obviously vary from builder to builder, but taking a simple and basic approach, we’ve narrowed down the numbers on what we estimate it will cost to build an Oram 45R.

To take a look at the full design specs, take a look here: https://www.boboramdesign.com/45r

For a quick look at the numbers, check our website: https://www.mjsailing.com/cos/oram-45r…

For a download of the spreadsheet, click here: https://www.mjsailing.com/wp-content/u…

After discussing previous builds with the many others who’ve come before us, we found out there is one small thing that can skyrocket a budget – and that is making customizations after you’ve started the build. But, if you start with good plans and commit yourself to them, it is very feesable to stick to your original budget.

Sending the above spreadsheet to both designers and builders, and asking if they were realistic figures, they all came back stating that we’ve covered all aspects and should be able to complete the project within the budget we have listed. And that, is music to our ears!!

Since this is a very long video because we have tried to keep it as detailed as possible, here is an outline of subjects covered if you’d like to bounce through to the areas that interest you:

0:00:00 – Intro by Jessica 0:03:50 – Intro by Matt 0:15:32 – Intro To Budget 0:16:30 – Costs relating to Kit 0:21:45 – Total cost of Kit shipped to the US 0:24:23 – Costs relating to Building Supplies 0:32:10 – Total costs of Building Supplies 0:32:53 – Total cost of First Year of Build (getting to paint stage) 0:35:41 – Costs relating to Paint 0:39:05 – Costs relating to Sailing (rig, sails and deck hardware) 0:45:17 – Total costs of Sailing 45:38 – Costs relating to Engines 0:50:42 – Costs relating to Steering 0:52:32 – Costs relating to Electrical System 1:00:50 – Total costs of Electrical System 1:01:07 – Costs relating to Achor (anchor, chain/rope, windlass, docking gear) 1:04:05 – Costs relating to Lights 1:07:17 – Costs relating to Galley 1:12:07 – Costs relating to Exterior 1:16:53 – Costs relating to Interior 1:17:45 – Costs relating to Heads 1:19:12 – Costs relating to Electronics 1:22:20 – TOTAL COST OF BUILD 1:26:40 – Closing by Jessica

Much love from England! Jessica, Matt & Georgie

9 Responses

Hey again M&J

Just watched you cost vid, pretty much covered it all. Awesome. I had another thought for you on the kit, ask Bob (Oram) or Jeff (Schionning) if shipping is mandatory with their kits. What I mean is, both use west system epoxy mostly although our kit also included atl kinetics resin for under waterline wetout, nevertheless you may be able to source that (and the various powder additives) locally rather than pay international shipping on it, same goes with double bias and uni glass, which leaves the composite panels. I have heard that designers may sell you the rights (single use) to the CNC files but it very much depends on if they know and trust the composite panel makers. If they do there may be a company similar to ATL in the US to make you the panels. Just a thought based solely on the absurdity of West being made in the US, shipped to Australia only to be shipped back.

Great to hear from you! *anyone reading this- Paul built a beautiful Schionning cat and did the best documentation I’ve seen of the process at Yikes.com.au

Funny, the first suggestion I received from Oram was to get my epoxy in the US. Not only is it cheaper, but apparently Epoxy is a hazardous material and just the mess of importing it is best to be avoided. But we’ll probably source the fiberglass straight from ATL. Â In the US it’s more difficult than it should be to get the designer’s suggested cloth weave and weight. Our common weights are just different enough to cause some problems that I don’t want to have to reengineer for.

I did a cursory budget for building the panels myself, but unless my supplier’s bulk pricing was way too high, the ATL price vs infusing my own panels were surprisingly close – and it was even closer getting them from Schionning’s South African manufacturer. Buying 200 sheets of Divinycell still didn’t get me into the price point to make it worthwhile 🙂 But adding the savings along with not needing shipping and import does get to the point that we’d essentially be paying ourselves a fair wage to infuse them, but I keep thinking that all it takes is one bad hull length infusion and we’d be at a large loss. It would give us continuous panels without need joints, but the South African panels are 40′ long and only need one seam now… so hardly a big benefit there either. That debate still rages on 🙂

Get out there and use that awesome boat! I can’t believe it’s been sitting on the mooring for so long without you guys at least using it as a power boat.

Hey Matt, As I suspected there’s not much you don’t already know or scoped out. I hear you regarding infusion. I did a bit of research into the kss Kelsall process but in the end decided I perhaps don’t have quite enough skill or attention to detail to be confident in my ability to infuse a 40ft panel, the last thing you want is delamination. But the “out of a mold†with paint already on sure is attractive, if I was ever to build again, anything that reduces fairing is worth it’s weight in beer in my opinion. And yes, all going well we intend using Yikes later this year, if only around our home port but I have to get the ammenities and comfort up to spec to get Jo on board. Loved the Thai charter adventure vids. Cheers Paul

Great video. Thanks for compiling all this together. It’s compelling enough that I’m seriously considering actually going for it.

Couple of questions: 1. I’m trying to scout the building locations. I live in an apt so no access to a big backyard. I know you mentioned leasing a parking lot potentially .. do you have any pointers. Logistically that seems like a huge problem that I’m struggling to overcome given that leasing an industrial warehouse (if I can find one with the doors large enough) would be at least 20K per yer for the ~2000 sq feet I’d need. 2. Have you considered Spirited Designs (as in Sail Surf Roam). What is it that ultimately made you go the Oram route? Designs seem very similar between Schionning and Oram and even the layout seems similar. 3. Oram build hours estimate and the overall cost seems much lower than Schionning. Did you figure out why that is or am I misreading something.

Thanks in advance! Good luck with your new adventure!

Build location is something we’re still struggling with too. I’ve been limited to online searches and emailing agents (Craigslist is a good source) since we are still in the UK and unable to travel back to the US to personally scout out locations. But since we can build anywhere we want, we can pick the best climate for our build (epoxies have some environmental requirements) Where are you located?

It’s almost impossible to find a warehouse with large enough doors to get a cat out in one piece unless it’s an airplane hanger. The typical way most ‘home” builders do it is to remove the wall of the warehouse to pull the boat out… it’s not that hard or expensive to do on a steel building. You just have to find a landlord that is okay with you pulling off the siding/wall and taking a frame or two down for a few days.

The Spirited Designs is a great boat, but for us, it has a few minor traits that we are looking to avoid. Plus, the 38′ is smaller and the 48’ is bigger than we want… no happy medium is offered.

The ‘Cost’ video was just our breakdown for the Oram 45R… like the build video showed the Schionning. We haven’t decided on a design yet- the Oram, Schionning and Grainger are all still 100% in the running.

The Oram is a simpler boat to build. It has a single seam at the sheerline- Schionning is multiple panels that need to be taped and faired- and it doesn’t have the extra seam on deck (another set of panels less on the Oram), and even the cabin top has one less seam (and another panel set less). For better or worse, the stock interior plan is more basic on the Oram too. One simple thing that save a lot of time is the lack of secondary floor (sole) in the hulls. Down below you stand on the hull itself without an additional raised floor like on the other boats.

I haven’t seen Oram list a lower amount of time for the build than Schionning (Grainger does show higher hours). Bob’s site say 5500-7500 hours for the 45R, while Schionning’s site says 5,000 for the Arrow 1360 (design comparison PDF). Schionning shows cost as $260,000 AUD for the 1360 and Bob say’s from $205,500 AUD to $265,500+

And a final FYI- Grainger is doing some redesigns of the Raku- along with new pricing- and will have that information out in the next few days. From talking to Tony, it sounds like they are making a big push this year. Shoot him an email (graingerdesigns.net) and he’ll keep you in the loop with the new detail.

Matt Johnson MJSailing.com

Thanks for that response. I’m down in Miami. I like the year-round warmth for epoxy curing but not sure about the rain/humidity/hurricanes. I’m debating whether I should entrust someone like Ojigawan to build it in VA and just make the trips there as often as possible but that takes the fun/experience of building out of the equation, limits the learning, and last/not least raises the cost 🙂

I did get a quote for the Schionning Arrow 1360 out of Pantawee in Thailand — PM me if you’d like to know what that looks like. In my calculation it comes down to the hourly rate of about $29 which seems very high given that the generous wages in Thailand are about $5 per day.

Good to know about Grainger — will keep my eye out for those new designs.

Did you ask Julian at Current Marine in South Africa for a quote on the Schionning? They maybe a bit more competitive than the Thailand builder since they have so much experience with Schionning (they build the foam kits that Ojigawan uses). I think they also offer pretty good pricing on mast, hardware and all the other needed supplies in SA. Take a look at Current Marine’s CM45 too- it’s an awesome Schionning design.

Good tip. Will reach out to Julian.

By the way — made some progress with locations with some help from my realtor friend. You can find ~ 3k foot parking lots in the Miami area for about 1-1.5k per month. Not cheap but certainly an option. Typically they’re in the industrial areas which have some local laborers that can help with fairing, etc.

Another interesting data point is that some of the builders are estimating about 6500-7000 hours for the arrow 1360 build and trust that 5k hours gets you a very basic/rough boat.

BTW — did you see those new Graingers? pretty sweet! Apparently they have a promotion if you’re willing to purchase plans in the month of June — not sure the details.

The discount is 10% off for the month of June. If you talk to Grainger, tell him we sent you… we get a referral for each customer that acts as a discount for our kit 😉

We’ve found lots for around $500, but those are nowhere near populated areas like Miami. Besides the rain, humidity, heat and cold, one of my big fears with building in a lot is security. We can lock up to tools and supplies in the shipping container, but I’m really looking for a good fenced in area, but this has been a bit harder to find in our price range.

I think 7000 hours is a pretty accurate timeline for a novice builder. I’ve spoken to a guy that built a beautiful Arrow 1280s in 4,000 hours, but that seems to be exceptional and not at all average.

Add a Comment

Your email address will not be published. Required fields are marked *

This site uses Akismet to reduce spam. Learn how your comment data is processed .

snapshots of building a sailboat

Building a sailing catamaran.

A collection of sailing catamaran building logs, from choosing sailboat plans to yacht launch...join us on our journey

This 'glass-over-ply' sailboat is proof that a DIY'er can successfully build an ocean-going multihull cost effectivly.

Having reliable Boatbuilding Resource Books , WILL HELP fast track your decisions prior to, during and post building.

We also wanted a light sailing catamaran that we could beach with ease. This now allows us to save money on one of the biggest maintenance DIY chores, sailboat antifouling without having the costly expense of slipway fees.

Where do I start?

Plywood and Epoxy Catamaran Why both?

Plywood construction is the cheapest building method available and very forgiving while one hones their skills.

Finishing with a solid fiberglass outer is also a task made easier, given the amount of glassing and gluing needed during such a project. Doesn't make sense? Read more...

Talk to the sailboat designers , get to know their design types. Get on Forums and ask the 'dumb' questions. Go to marinas (not boat shows) and look for home-build yachts.

how to build a boat

"It takes a strong desire and a will to achieve. Building a large catamaran is certainly achievable". "If you want a yacht with all 'bells and whistles', keep working because it costs money...a lot of money". J Coomer

many sailboat plans to choose from!

Is it cheaper to build or buy? There are many yacht plans to choose from, but dont kid yourself. Many have tried to do it on the cheap and their result shows. If there was a cheaper way, the sailboat designers would tell you. Afterall, they would use that reason to sell there plans!

catamaran sailing

DIY boat projects on Pure Majek from new navigation equipment, anchoring systems, rewiring yacht electronics diagrams, AIS and much more. Its been ten great years since launch and we look at things that have worked and those we would change. Join us and be inspired.

goal setting, planning and building

Setting achievable goals and how to stick to them. From the planning process, what and why we did many things, importantly, things we would do differently. The following pages draw on these experiences described in far more detail in our book ' A Sailing Catamaran Building Adventure '

‘Green power’ is climbing up the priority ladder to such an extent nowadays that some predictions of fossil fuel costs (scorned at a few years ago), are coming home to roost.

two-pack painting

There are a few tricks here to with respiration, thinning of the topcoat, temperature and coat thickness. All achievable by setting goals and being disciplined .

Building catamaran Pure Majek videos

Just want videos? Click our Youtube Channel . Over 500,000 views and counting. NO TALK videos . Thank you for your support.

Catamaran Hulls

Click photo

Catamaran Fitout

Catamaran Internal Painting

Bridgedeck & Turret

External Painting

Final Fitout

Antifoul & Decktred

Fitout, ready for launch

building: puremajek.com

sailing: diycatamaran.com

© Copyright 2009-2024 www.diycatamaran.com - All Rights Reserved

No video? EMPTY CACHE from your device, then UNMUTE .

No video? EMPTY CACHE from your device, then UNMUTE .

Starting out

Internal Painting

Bridgedeck and Turret

No video? EMPTY CACHE from your device, then UNMUTE .

- Testimonials

P: (+61) 02 4981 8288

Disclaimer Copyright © 2013 Spirited Designs. All Rights Reserved.

Time For a Catamaran Adventure

Isn't Time For Yours?

Building Your Own Catamaran

Building your own catamaran is another option to getting into your own boat. In this page we will go over the advantages, considerations, and a detailed history and journal of our boat-building adventure with Light Wave . We hope this will give you a clear picture of what lies ahead if you go this route, including:

- Construction methods

- 9 essential design features

- Review of the four leading catamaran designers for home builders

- Construction times

- Budget: How much did it cost to build a basic cruising catamaran?

- Layout of our catamaran, LightWave , and lots of pictures

- Carllie’s article from September 2000 Multihulls Magazine: “The Boat Builder’s Wife “

- Equipment outfitting

- Radio and communication outfitting

- Dinghy selection and considerations

- Having a boat custom-built for you

Because of the huge dollars needed to buy a new or even a used catamaran, we would never have gotten a catamaran if we hadn’t built it ourselves.

Let’s start by saying that building any type of larger boat, especially a catamaran, can be one of the most intellectually and physically challenging things you will ever do.

It has been said that building a large boat is the closest a man can come to giving birth to a baby. In other words there is going to some discomfort and pain along the way; you will question yourself on whether this was such a good idea; it’s very difficult to reverse the decision; and though friends will support you, you will be on your own most of the time with your significant other if he/she is game.

Know your boat

You will intimately know every part of your boat. You will know where every wire, hose, bolt, bulkhead, rib, and support is because you installed them!

Pride of ownership

We have often thought what it would be like to just buy a boat from a manufacturer, and know that while owners who have spent a lot of cash (or future life to pay off the lien) their often possessive and competing-with-the Joneses could not begin to compare to our quiet glow of happiness and akinship we feel with Light Wave .

Our boat is like part of the family. So much time was spent on her that we have a major emotional investment. Every time we see our vessel – from a distance at anchor or approaching her in our marina, we say, “What a pretty boat! I can’t believe we built it!” Then that sense of accomplishment settles back in and we feel we have indeed earned the privilege of all of the beautiful experiences we have had sailing, cruising, exploring the beautiful BC Coast and much further a field (or should we say “an ocean”?).

You will be able to pay for the materials as you go and “donate” your time to the cause.

Get a newer design

Many of the production boats that are out there are designs of many years ago because the manufactures have to recoup their capital investment on the mold and production setup. When you build your own you have much newer designs to draw from.

Details on Our Boat Building Adventure

We had sailed our first boat Wave Dancer for five years and had many adventures on the British Columbia coast. In May 1996, I had just returned from a little one-week solo trip in the Gulf Islands of BC when I bought the book, The Cruising Multihull by Chris White (Future link to book review on our web site).

This is the book that got me going (Carllie was not yet convinced). I must have read it a half dozen times over the next 6 months, each time becoming more convinced that this was the way to go for our next boat. It was really still pre-internet web site days so I wrote to all the designers that were listed in the back of the book. Over the next several weeks packages of information started appearing in the mailbox (there is just something about getting packages in the mail – I guess it’s the anticipation). I would pour over these preliminary printed pages with pictures and accommodation layouts. Next, I put a few dollars down to buy the information packages and study plans from the top prospects.

I waited patiently for the study plans. It was like the night before Christmas when I was kid. Oooh the wait! Finally they came, and again I carefully scrutinized the next level of detail. Things were getting a little more serious. The top contenders were:

- Richard Woods

- Chris White

- James Wharram

Click here to read my comments and reviews on their catamaran designs as well as those of Jeff Schionning.

I remember initially drooling over the Atlantic 42 by Chris White, still one of my favorite designs. It seemed to be so seaworthy (by the way if I run into about $800,000 USD any time soon, I am going to buy an Atlantic 55). The most important piece of advice that came out of the material was from Richard Woods:

“Build the smallest boat you‘d be happy with it.”

Axiom #1: The hours to build a catamaran is in almost in direct proportion to its weight.

Which brings us to Axiom #2:

Axiom #2: It takes about 1 hour to create 1 pound of finished boat.

In our case we spent 3,500 hours ( click here for full details on the construction hours ) to build a 4,000 lb. boat (just a little less than 0.9 hours per pound). If a boat’s empty weight is 8,000 lbs., it will probably take about 6,000 hours to build.

When you think about it, you can only mix and handle so much material per hour. More boat weight, more material, more hours. Sure there are some economies of scale on a bigger boat, but usually the systems become more complex and these take longer to install.

This decision process took 8 months and I figured we’d launch in 6 months. It was now January of 1997. Little did we know it would be 26 months and 3,500 hours between the two of us until we launched on June 5, 1999. We ordered the full plans and we were off and running.

We were ready to build, but where would we start the process? First of all, we live in a tiny 480 sq. ft. apartment in Vancouver. Back-yard building wasn’t exactly an option so I found a small garage nearby that we rented for 5 months.

After about 4 months in the garage, I had made all the small parts and it was time to build the hulls. This meant that we had to go larger facilities. We found space at Shelter Island Marina and Boatyard in Richmond. This is the biggest boat yard in the Vancouver area with dozens of commercial and private projects, big and small, under way.

We were out of money by then, so we sold our first boat so we could buy resin and fiberglass. It was a traumatic time as we said goodbye to our beloved Wave Dancer . We were now committed. We than had all the foam for the hull cores, barrels of resin, and huge rolls of matting and roving needed for the fiberglass skins delivered to our “domed stadium”. We kicked ourselves many times that we didn’t take a picture of this raw material stacked in one corner of the empty shed, so we could later show “before” and “after” photos. It was time to build the hulls.

Over the next several months we proceed to join the hulls with the beams I had built in the garage, and then to install the cuddy cabin, cockpit, and decks. By the spring of 1998, it was staring to look like a catamaran. Through the spring and summer of 1998, we continued with the major structural components: mini-keels, hatches, stairs, and interior. Then we went on to the very laborious work of fairing the boat before painting. Don’t under estimate that job!

By October 1998 we were ready to prime the boat and start painting. I really thought this would go quickly. I forgot that I would have to do two more complete sandings to sand off and finish the two layers of primer application. In addition we had to fill countless pinholes – a laborious process somewhat like hiking up a mountain – each time you get to what you think is the top, you see another summit!

The boat seemed to get bigger and bigger. Believe me, there is a lot of surface area on a catamaran. I clearly remember that last sanding: I had reached the end of my physical and mental endurance – I was exhausted. I was ready to move on to the next phase – any phase but more sanding!

We now started spray-painting the hulls bright yellow. It was around this time we decided on our boat name of Light Wave . The painting took over a month: the hulls being the easy part, it was the topsides, the nonskid, and all the masking and prep that seemed to take forever. Happily, the worst of the dust was gone.

By March 1999 we were in the home stretch. The center bridge deck cabin was completed so we took a week off from our paid jobs and lived on the boat in the shed so we could work all day and not waste time commuting. March, April and May were frantic months as we finished all the final touches: engine installation, rudders, windows, deck fittings, electrical, plumbing, mast, and rigging. See our outfitting page (for more details on what we picked and why, and things we would do differently now.

Initially, our electronic systems were relatively basic but included GPS and autopilot see the following link for all our electronic outfitting choices and reasoning for more details.

It was May 22, 1999 and we decided that Saturday, June 5th would be “Launch Day” so we could send invitations to all of our friends. On the Friday night before Launch Day, we still had a number of final things to do, many of them outside. Unfortunately it was pouring rain. We were tired and very wet but the boat had to go into the water next day so we persevered on till everything was ready.

The moment of truth came as Light Wave was lowered into the water. While still in the slings of the Travelift, I jumped aboard to check for leaks. Of course there weren’t any! More food and laughs and tours of the boat for all attending. It was a great day.

Emotionally drained that night, we slept in Light Wave in the water for the first time. It was another week before we actually went out for our first trip as we had to sell the shed, setup sails, and install some final deck hardware.

To sum it up, building a catamaran was a great experience. We learned a lot. Carllie and I grew closer together through it all. We had a great time doing it. We had a beautiful catamaran to show for it. Now it was time for a catamaran adventure !

[email protected]

kit materials' Contents

So if you order a schionning kit, what exactly is going to arrive see an overview of the materials you will receive, and what each is used for during the build process. fibreglass cloth or tapes microspheres, microballoons or microfibers take a closer look and you can answer these questions., our schionning kits are a no nonsense, common-sense approach to building a boat. we offer great service, fast delivery and access to anything you could need for your boat straight from the supplier to your door. our construction plans and kits are sold with 100% professional boatbuilder support via phone and email, any time you're unsure or just need a second opinion, we're here..

Our kits contain all of your basic materials to build your boat to a faired shell stage, ready for painting and fit-out. We have sail-away costing estimates available for all of our standard designs, and this will give you an accurate idea of the overall cost of your project. This costing varies depending on your level of finish, as you can imagine different options vary greatly in price.

Below is a quick glance at what your Schionning Kit will include and what each item is primarily used for, we hope this is helpful and if you should require more detailed information please don’t hesitate to contact our office.

What do I actually receive?

DUFLEX PRE-LAMINATED PANELS

DuFlex pre-laminated panels are the main and most important material used in our kits, predominantly in the flat panel designs, however they are used in Strip-planked designs also, though to a lesser extent. These panels are 2400mm x 1200mm and are CNC routed to speed up build time on our Wildernes X Series, as well as some of our power designs. For internal furniture, a paper honeycomb core is used instead of the end-grain balsa wood core that is used for main structural areas. The use of this is purely to save weight in the shell and therefore produce a faster, more responsive catamaran.

KINETIX LAMINATING RESIN & HARDENER

WEST SYSTEM EPOXY RESINS

FIBREGLASS TAPES (DOUBLE BIAS)

CARBON FIBRE CLOTH

FIBREGLASS CLOTH

James Wharram Designs

Search Our Site

Mana 24 - self-assembly 'cat-kit', wharram's first kit boat.

Introducing the CNC-cut self-build 'Cat Kit', a trailable family camping boat. All plywood parts are pre-cut - just take it out of the box and assemble it yourself! Keep it at home, trail it and sail it anywhere. MANA is the Polynesian word for 'spirit' given to an object by its maker or the person that uses it.

An Economical Way To Enjoy Sailing

Due to the present period of financial austerity and increasingly high marina costs, a large number of would-be sailors are having a hard time financing the dream of sailing their own boat.

However, there is an economical way to enjoy sailing, by building your own small lightweight boat, keeping it at home and trailing it to the waters you want to sail in , chasing the good weather. This gives the opportunity to explore many more sailing areas than if based on a permanent mooring and at a much lower cost.

In designing the MANA, we explored this idea and looked sideways into the world of camping and have combined the innovative CNC cut "flat pack" boat-building concept with the philosophy of outdoor living to create the unique MANA camper-sailer, specifically designed for trailer sailing.

All these ideas have come together, resulting in the new MANA 24 design, a catamaran specifically designed for trailer sailing. The MANA kit is sold with all the plywood cut out by CNC cutter , so building the boat at home will be a bit like assembling a flat-pack . All the parts slot together perfectly so a hull can take shape in a day.

Building from such a kit takes away the worry of measuring and cutting all the boat parts, which can be quite daunting to many first time builders and saves a lot of time in the early stages of building. As she is built from a pre-cut kit, we have been able to give the Mana more complex and beautiful shaping , giving her more interior volume than the Tiki designs. During construction all the kit parts slot together and are locked with wooden wedges, so no room for error. Even all the stitch holes (for fastening joints with cable ties) are drilled and lines scribed where to glue on bearers and stringers.

MANA's 23'6" hull length has a special significance for James Wharram . In 1956 he made the first successful catamaran voyage across the Atlantic in his first catamaran, the 'Tangaroa', also 23'6" long.

In trailer/sailer design every increase in length equals harder launching and recovery work. At 23'6"- 7.15m hull length MANA 24 sits between our TIKI 21 and TIKI 26 designs (both very popular trailer sailers), with easier launching and handling like the smaller TIKI 21, but an interior space close to that of the Tiki 26 . Her new chined hullshape gives more width for the bunks, which are placed aft where the hulls are widest, and where there is least motion.

For speedy assembly the hulls and beams of the MANA are connected with quick-fit webbing straps with over-centre buckles, which are very strong and much easier to fit than bolts.

With the main mast of the MANA placed well forward the platform gives ample flat space for a low cost dome tent or a custom-made pramhood tent, which can double as spray hood when sailing. Adapting camping habits to a sailing lifestyle gives wider sailing opportunities at minimum cost and lots more family fun!

MANA uses the well proven Wharram Wingsail rig in a new Catrig configuration. The Wingsail rig is a modern version of a high aspect Dutch style gaff rig, sleeved round the mast for maximum aerodynamic efficiency.

In this new Catrig configuration the mainsail gives the drive with a very clean leading edge. The small mizzen aids with balance, steering and tacking . Having no jib, there is no need for a very tight forestay. The standing rigging uses the latest dyneema rope, which is light and easily set up. The mizzenmast can be used as sheer pole for single-handed assembly.

Mana 24 Design Data

What You Get In A Mana Kit

CNC cut plywood parts, timber parts, epoxy materials, fastenings, ropes, blocks and fittings are all included in the kit. See the price list .

Transporting The Mana Kit

The entire kit can fit and be transported in the back of a van with ease. The van in the photos is a VW Transporter.

Boat In A Box

Your Mana 24 kit will arrive in a box like this!

We're Taking Orders

The Mana 24 kit is now available and we are taking orders. We will be handling each order individually due to different options and shipping costs, so if you would like to discuss ordering a Mana kit, please contact us , we will then be able to work out shipping details to your building site and supply you with a pro forma invoice.

Cost of complete kit, including all fittings, masts and sails is £12,750 (if bought complete, separate costs below). All prices excluding VAT, and excluding shipping costs (shipped FOD, Freight on Delivery).

If your budget is tight, it is possible to buy the kit in two stages , buying masts, sails, rigging, ropes and fittings later. Or you can buy just the basic Boatbuilding Kit which includes the building rights and plans, and source fittings, rope and fasteners yourself as all are detailed in the plans.

1. Boatbuilding Kit - Total Cost £9,975

- Complete set of plywood parts to build two hulls, crossbeams and motorbox, CNC precision cut. All plywood Robbins Elite BS1088 Marine Plywood, guaranteed for 15 years, manufactured from selected Gaboon (Okoume) veneers throughout

- Platform panels, 2 large, 2 small, prefabricated from 40mm plastic honeycomb, glassed top and bottom

- Small hardwood timber parts, CNC cut to size, ready for final shaping, sanding and fitting

- Perspex windows and washboards, CNC precision cut

- WEST Epoxy kit, includes all resins * , pumps, fillers and glass cloth, mixing sticks, 1 box vinyl gloves, 1 rubber squeegee

- Sikaflex 295 for fitting windows

- Sikaflex 221 for bedding fittings etc

- Neoprene rubber for sealing hatches

- Rubber for padding beam mounts

- Gripfast nails, stainless steel machine screws, cable-ties and roller-sleeves (to be cut into paint/epoxy-pads), 2 paint-pad handles.

- Douglas Fir timber for stringers, framing etc and hardwood for hatch coamings (mahogany) and keel strips (iroko), all in long lengths to be cut to size by builder *

* N.B. For overseas customers Boatbuilding Kit should be bought excluding the long lengths of Douglas Fir and hardwood timber for easier transport. Cost deducted by £1100. We can also not include the epoxy resin and hardener as these are hazardous products with freight restrictions. You will need to buy these through your local dealer. Cost for these deducted by £900. (i.e. Cost of Boatbuilding kit excl. long timber and epoxy £7,975).

2. Blocks, Fittings And Rope Kit - Total Cost £1,200

- All blocks, cleats, shackles and other fittings to rig the Mana

- All ropes for sheets, halyards, lanyards and standing rigging (Dyneema)

- Stainless steel buckles and webbing straps for crossbeams

- Shockcord for tillers and hatches

- Aluminium boathook/mizzen boom

- Set of fittings for both mastheads and hinging unit for base of main mast, fabricated from aluminium and stainless steel

3. Sails, Made By Jeckells Of Wroxham - Total Cost £1,530 (Specify Colour)

- Mainsail with two reefs

- Mizzen with 1 reef

4. Masts * - Total Cost £510

- Aluminium mast tubes. 4 ½” OD x 10swg for main mast, 2 pieces @ 5m and 2.30 long, plus sleeve. 3” OD x 10swg for mizzen, 4m long.

* N.B. For overseas customers we suggest you source your mast tubes locally as shipping long lengths will be costly.

Building Time Estimate

We kept precise building hours while building the prototype. We built to a high quality standard with excellent finish, i.e. a lot of time spent on precision sanding, fairing etc. Building time in the early stages of building is greatly reduced by the CNC cut plywood parts, which takes away all the worry of measuring and cutting and lets the builder assemble the hulls very quickly.

Summing Up Of The Times We Took

- All construction work; hulls, beams, gaffs, tillers, hatches, including epoxy coating all interior surfaces: approx. 500 hours

- All exterior glassing work; hulls and crossbeams: 90 hours

- All sanding of glassed surfaces: 45 hours

- Painting, two coats epoxy primer, two coats 2-pack topcoat incl. non-slip decks and antifouling: approx. 80 hours

N.B. What should be noted is how many hours it takes to do sanding and painting compared to the building time. Glassing, sanding, fairing and painting add up to 30% of the total building time. On our basic building time estimates in our Design Book, final finishing and painting are not taken into account. Working from a kit does save many hours.

Transport Sizes And Weights

- The plywood kit, including made-up platform panels will be in labeled bagged bundles measuring in total approx. 2.5m x 1.20m x 0.3m and weighs around 300kg

- Fastenings, blocks, fittings and ropes, 1 box, approx. 60 x 40 x 30cm . Weight 25kg

- The WEST epoxy kit measures approx. 1.3m x 0.6m x 0.45m and weighs around 100kg

For overseas transport the above items have to be packaged in one special wooden pallet crate - 2.62m x 1.29m x 0.77m - at additional cost of £250.

- Timber will be a long parcel (around 3.5m - 4m long) and will weigh around 50-60kg

- Aluminium masts, in max. 5m long sections , weight incl. fittings 40kg

For overseas customers we advise them to source the timber and masts locally.

You will be able to collect the complete kit from Cornwall, UK yourself on a trailer or in a van saving on a lot of shipping costs and paperwork.

Interested in building a Mana? Contact us now:

Projects: Constructing a 40ft catamaran with WEST SYSTEM epoxy

Work doesn’t necessarily slow down after retirement, as engineer Martin Ellison proved when he left his teaching post at the age of 59 and set about building his first boat. What started as some prompting from his wife to find a meaningful project evolved into the idea of building a 40ft catamaran. Martin tells epoxycraft how it all came about.

I have always loved being on or near the water and wanted to have a boat of my own. As someone who has renovated a few houses in the past, I wasn’t daunted by the idea of building a wooden boat from a set of plans, although I’m not sure it was the scale of project my wife had in mind!

I chose to build a catamaran because I wanted the space and stability; preferring a power cat, I searched online for some designs and went for the Skoota 36 ( Woods Designs ). This is a relatively simple timber and plywood design sheathed in fibreglass, although I have slightly modified the design to increase the length to 40ft so that I could enlarge the accommodation space in the hulls.

When I began in earnest in September 2014 I didn’t even have a boat shed, so that was the first project. It was ready for action by March 2015 and I have been steadily working on the boat for the past nine months.

I’ve used WEST SYSTEM epoxy all over… and found its strength and versatility to be ideal.

For the build I’ve used WEST SYSTEM® epoxy all over – jointing, filleting, waterproofing and sheathing and have found its strength and versatility to be ideal for this project.

I’ve mainly used WEST SYSTEM 105 Epoxy Resin® with WEST SYSTEM 205 Fast Hardener® . In addition, I’ve combined the epoxy mix with WEST SYSTEM 403 Microfibres and WEST SYSTEM 409 Microsphere Blend® to ensure all the gaps have been thoroughly filled. When it came to sheathing, I used 300g and 600g Episize™ Biaxial Fabric and 300g woven WEST SYSTEM 787 Aramid Fabric® to provide extra protection below the waterline.

The boat build so far has taken just over 1100 hours. It’s a big boat and there’s a lot of work – mainly woodwork – involved in completing each stage. I’m enjoying it though, it’s very rewarding and most of the build has gone pretty smoothly.

As luck would have it there is another Skoota 36 being built in Canada which is about one year ahead of me and the owner has very kindly shared his build photos, which has been a great help. People say it looks very difficult but in practice it isn’t – it’s simply a case of following the plans and having the confidence to get on with it.

There’s still a bit of a way to go but I’m really looking forward to turning over so we can finalise the internal layout and then getting her in the water and cruising in her.

Our thanks to Martin Ellison for sharing his story. We wish him well and will be following him closely as he completes his build.

If you would like more information about this project you can follow the build on https://my-new-cat.weebly.com

Back to projects

How Can You Repair a Hole in a Fibreglass Boat?

Can Gelcoat and Epoxy Bond?

How Did I Become a Skipper Through Boat Restoration?

- Skip to main content

- Keyboard shortcuts for audio player

Weekend Edition Sunday

- Latest Show

Sunday Puzzle

- Corrections

Listen to the lead story from this episode.

Politics chat: Biden and Trump pin their hopes on debate to give them an edge

by Tamara Keith , Mara Liasson

Meet the woman who escaped two conflicts — as a Palestinian refugee, then in Ukraine

by Tamara Keith , Eleana Tworek

Biden will address the commencement ceremony at Morehouse College. Protests are expected

by Tamara Keith , Stephen Fowler

These teens were missing too much school. Here's what it took to get them back

by Leigh Paterson , Elizabeth Miller

Plant-based restaurants are adding beef. Does the climate math add up?

by Tamara Keith , Julia Simon

An iconic chocolate factory shuts shop in Chicago

by Michael Puente

Sunday Puzzle NPR hide caption

Sunday Puzzle: Complete the compound with these animal connections!

by Will Shortz

Tree seeds that flew around the moon are now being planted across the U.S.

by William Joseph Hudson

Music Interviews

Sudanese musician sinkane on his new album 'we belong'.

by Tamara Keith

The Supreme Court ruled to protect the CFPB. Here's why it matters for your money

Middle east, anger at netanyahu cuts through a somber tel aviv rally to bring home the hostages.

by Hadeel Al-Shalchi

Trump addresses NRA's annual meeting, urges them to vote

by Tamara Keith , Caroline Love

A London court will rule on Julian Assange's extradition to the U.S.

by Tamara Keith , Willem Marx

Rock icon or a victim of exploitation? Examining Amy Winehouse's legacy

by Tamara Keith , Stephen Thompson

Scientists at Berkeley develop a tool to help cities measure carbon emissions

by Kevin Stark / KQED

Furiosa makes a splash at the 2024 Cannes Film Festival

Environment, on a trail in the adirondack mountains, runners appreciate the spring season.

by Emily Russell, NCPR

Author Interviews

Hold on to your wishes — there's a 'spider in the well'.

by Tamara Keith , Samantha Balaban , Melissa Gray

Searching for a song you heard between stories? We've retired music buttons on these pages. Learn more here.

China Builds World’s First Dedicated Drone Carrier

China has built the world's first dedicated drone carrier. the ship has not been reported however and many of the circumstances surrounding it remain a mystery..

H I Sutton 15 May 2024

Hidden away in a shipyard on the Yangtze, far upriver from the major yards at Shanghai, is a new aircraft carrier. It’s China’s fourth, a ship whose mere existence has not been reported before. Only China can build an aircraft carrier in relative secrecy.

This ship, launched in December 2022 but not reported until now, is surrounded by mystery. Naval News, together with J. Michael Dahm, Senior Resident Fellow at the Mitchell Institute , have been analyzing it.

Mysterious Drone Carrier

The world knows about China’s first three carriers; the largest and most capable, the Type-003 Fujian, is currently undergoing sea trials . This new carrier is very different. Its claim to fame will not be that it is larger. Instead, we are confident that this ship is the world’s first dedicated fixed-wing drone carrier.

The design is smaller than the regular aircraft carriers, with a flight deck approximately one third the length and half the width of a U.S. Navy or Chinese Navy (PLAN) super carrier. For comparison, it is slightly shorter but wider than a World War Two escort carriers. It would be possible to operate fixed wing aircraft from it, but its straight deck arrangement would be anachronistic, not allowing aircraft to take off and land at the same time. Additionally there doesn’t appear to be space for a typical aircraft hangar, so the number of aircraft would be greatly limited. It does make sense as a drone carrier however.

Drones are an increasing part of naval warfare. Leading navies are already trialing them from regular aircraft carriers. And some navies, notably Iran and Turkey, are working on plans for ‘drone carriers’. But this space is still in its infancy.

Analysis of the ship

It is immediately apparent that it is, in general arrangement, an aircraft carrier of some sort. It has a marked runaway running along the port (left side) with an island superstructure on the starboard (right) side.

Beyond this, it is unusual in every respect. The hull is a widely spaced catamaran. While catamarans are often featured in aircraft carrier concepts because they allow a large deck area, no one has actually built one before. Additionally, analysis of satellite imagery shows that the flight deck is very low. It appears unlikely there is a hangar deck below the flight deck. If there is, its ceiling is very low. Therefore, it does not appear designed to support high tempo or prolonged flight operations.

The flight deck is wide enough to comfortably operate aircraft or drones with a wingspan of around 20 meters (65 feet) such as Chinese equivalents of the Predator drone.

However, the mere existence of a flight deck suggests that aircraft intend to land on it. A catapult or launch rail of some form would be sufficient for launch if recovery wasn’t necessary.

Potential roles for this ship

J. Michael Dahm notes that the shipyard where it is being built, Jiangsu Dayang Marine, has previously built simulated enemy ships for the PLAN. China has an extensive program of simulating Western and Western-leaning navies’ ships in its weapon testing program. Its anti-ship ballistic missiles are tested on full-size outlines of U.S. Navy aircraft carriers .

Several high-tech target barges and two large dr one motherships have already been built at this shipyard. All these perform as opposing forces in training, a role known as ‘Electronic Blue Force’. So it is possible that this ship too is designed to support that mission.

Whether it is intended for Blue Force simulation or purely research and development remains to be seen. Similarly, we question whether it is an official PLAN program or a speculative commercial project. The new drone carrier remains something of a mystery. Watch this space.

Related Articles

Chinese Experimental Corvette Starts Sea Trials

France Orders First Long Lead Items for PANG Aircraft Carrier Program

Chinese Aircraft Carrier Fujian Prepares For First Sea Trial (Updated)

Qualcomm’s Snapdragon Dev Kit is a compact PC designed to help build Copilot+ PC apps

- Share on Facebook

- Share on LinkedIn

Join us in returning to NYC on June 5th to collaborate with executive leaders in exploring comprehensive methods for auditing AI models regarding bias, performance, and ethical compliance across diverse organizations. Find out how you can attend here .

Qualcomm wants to help speed up app development for the AI PC — or is it Copilot+ PC? — age. At this year’s Microsoft Build conference, it introduced the Snapdragon Dev Kit for Windows, a compact PC powered by a Developer Edition of its Snapdragon X Elite chip.

“The Snapdragon Dev Kit for Windows is purpose-built to accelerate the next generation of on-device AI applications for PCs,” Kedar Kondap, Qualcomm’s senior vice president and general manage of compute and gaming, says in a statement. “This system gives developers access to our powerful Qualcomm Oryon CPU and 45 TOPS NPU, so they can build the AI apps of the future.”

This isn’t like a mini PC you’d buy for private use. Rather, it’s specifically for AI PC app development. It runs the Windows on Snapdragon toolchain natively and is equipped with runtimes, libraries and frameworks developers might need to build AI-powered programs. It also has multiple ports that make this device compatible with multi-monitor systems.

Using this compact PC, developers have an environment from which they can create, debug and test apps and experiences for the slate of AI PCs supported by the Snapdragon X chip.

The AI Impact Tour: The AI Audit

Join us as we return to NYC on June 5th to engage with top executive leaders, delving into strategies for auditing AI models to ensure fairness, optimal performance, and ethical compliance across diverse organizations. Secure your attendance for this exclusive invite-only event.

This isn’t the first Snapdragon-focused kit Qualcomm has made available, and it’s not the only one specific to AI. It has its Qualcomm Innovators Development Kit , which facilitates building app prototypes for various applications, including on-device AI. There’s also the Snapdragon Mobile Hardware Development Kit , helping developers create new devices like smart cameras or next-generation tablets. Qualcomm also has a Cloud Edge AI Development Kit , but it’s not a PC—it’s similar to a wireless router with an antenna, runs CentOS 8.0, and is used to power AI and video processing.

However, the Snapdragon Dev Kit stands out because of its form factor. It is meant for apps running on Snapdragon X AI PCs. And there are a lot of these laptops, thanks to Microsoft’s Copilot+ PC announcement earlier this week. With the possibility of so many of these devices in people’s hands, it’s time to accelerate app development.

Developers can buy the Snapdragon Dev Kit starting June 18. It has a retail price of $899.99.

Stay in the know! Get the latest news in your inbox daily

By subscribing, you agree to VentureBeat's Terms of Service.

Thanks for subscribing. Check out more VB newsletters here .

An error occured.

Snapdragon Dev Kit For Windows Launched At Microsoft Build. Price, Availability, More

At microsoft build, chip making giant qualcomm announced the snapdragon dev kit for windows, a compact pc powered by the snapdragon x elite, developed in partnership with software giant microsoft..

At Microsoft Build, chip making giant Qualcomm announced the Snapdragon Dev Kit for Windows, a compact PC powered by the Snapdragon X Elite, developed in partnership with software giant Microsoft. Specifically designed for developers to create or optimise apps and experiences for the next generation of artificial intelligence (AI) PCs, this kit arrives just in time for the launch of Snapdragon X Series-powered laptops next month.

The Snapdragon Dev Kit enables developers to optimise Windows applications for Snapdragon processors. Using familiar tools like Visual Studio and VSCode, developers can easily recompile their apps directly on the Dev Kit.

Snapdragon Dev Kit For Windows Price And Availability

The Snapdragon Dev Kit for Windows is available today (May 21) for pre-order, with retail availability on June 18. It will cost $899.99.

“The Snapdragon Dev Kit for Windows is purpose-built to accelerate the next generation of on-device AI applications for PCs,” Kedar Kondap, senior vice president and general manager of compute and gaming, Qualcomm Technologies, Inc., said in a statement.

“This system gives developers access to our powerful Qualcomm Oryon CPU and 45 TOPS NPU, so they can build the AI apps of the future," Kindap added.

Snapdragon Dev Kit for Windows aims to be the best possible experience for PC users by leveraging the native Windows on Snapdragon toolchain. The Dev Kit features a high-performance Snapdragon X Elite chip and numerous ports, making it ideal for developers who use multiple monitors. With a wide range of Snapdragon X Series powered laptops hitting shelves soon, developers will have access to incredible new technology, thus, enabling them to create fully-optimised software and AI experiences.

Using the native Windows on Snapdragon toolchain, including Visual Studio/VSCode and many other runtimes, libraries and frameworks, the Dev Kit lets developers quickly adapt and recompile Windows applications natively for Snapdragon, helping to deliver PC consumers the best possible experience. The Snapdragon Dev Kit for Windows features a special, accelerated Developer Edition of the Snapdragon X Elite processor, along with an array of ports and a form factor designed to be compatible with developers’ multi-monitor systems.

Top Headlines

Trending News

Photo Gallery

Trending Opinion

Personal Corner

- International

- Today’s Paper

- Premium Stories

- ⏪ Election Rewind

- Express Shorts

- Maharashtra HSC Result

- Brand Solutions

Microsoft Build 2024 highlights: New AI features on Windows, Snapdragon Dev Kit, and more

At build 2024, microsoft announced new ai services and tools for developers and customers..

On Monday, Microsoft concluded Build 2024, its annual developer conference, just a day after introducing Copilot+ PCs powered by the Snapdragon X Elite/Plus processors. Satya Nadella presented the keynote.

Microsoft announced several new features for existing products, new solutions, and more at the conference. Here are some of the announcements:

Windows updates

Microsoft is adding AI agents to more products and services. AI agents can now be used like a virtual employee; it can monitor emails, perform automated tasks, and can even help with an employee onboarding process. These features will be available via the Copilot Studio later this year.

Microsoft Team meeting app will soon gain the ability to create and share custom emojis, and the Windows clipboard will gain generative AI capabilities, powered by OpenAI models. It will also get advanced copy and past capabilities via the PowerToys, allowing users to directly summarise, translate, and rewrite, or even generate a code based on the context provided.

File Explorer on Windows 11 is also gaining a new feature. Users can soon use Explorer to keep track of projects, including integration with the GitHub repository. It will also gain native support for 7-zip and TAR compression formats.

Snapdragon Dev Kit for Windows

Microsoft also announced the Snapdragon Dev Kit, a mini PC powered by the Snapdragon X Elite processor, priced at $899. It comes with 32 GB RAM and 512 GB of internal storage. It looks similar to a Mac Mini and is meant for developers to build and test native ARM64 apps for Windows 11.

Announcements for developers

Microsoft also made several developer-centric announcements, including GitHub Copilot extensions, featuring GitHub Copilot for Azure. Users can now customise GitHub Copilot using third-party services like Docker and Sentry. Similarly, GitHub Copilot for Azure also allows users to quickly deploy Azure using natural language.

Azure AI Studio is now available for everyone and Microsoft is expanding 20 Responsible AI tools and 90+ features in Azure AI with Azure AI Content Safety. Developers can now access OpenAI’s latest flagship model GPT-4o via Azure AI Studio and as an API. Microsoft is also adding a new Azure virtual machine, powered by a Microsoft custom silicon and it is now the first cloud provider to integrate AMD’s versatile MI300x AI accelerator chip, optimised for GPT-4.

Similarly, Microsoft also unveiled a new AI model – Phi-3-vision, which is a multimodal AI model that can process texts and pictures. This is said to be a small language model (SLM), which can natively run on mobile devices such as laptops with a dedicated NPU. Besides, the company is also making its Edge web browser even smarter, with an ability to translate YouTube videos in real-time. It currently supports languages like Spanish, English, German, Hindi, Italian, and Russian.

Actor Jason Shah was immediately drawn to Bollywood after appearing as an extra in Salman Khan's Partner. He praised Salman's relaxed demeanor on set. Other co-stars have also shared stories of Salman's tardiness, with Kubbra Sait and Grusha Kapoor recalling waiting for hours on set.

Best of Express

May 22: Latest News

- 01 Porsche crash: ‘What will people on streets do? Something needs to change in this situation,’ says judge

- 02 Pune crash: Realtor father of teen driving Porsche held for letting him drink, drive

- 03 Kathmandu Post chairman held over ‘citizenship misuse’ issue

- 04 Long queues outside petrol stations on the third day of CNG shortage

- 05 Worker dies while cleaning water tank in Jogeshwari; family suspects electrocution, negligence

- Elections 2024

- Political Pulse

- Entertainment

- Movie Review

- Newsletters

- Web Stories

- United States

- United Kingdom

Microsoft Fabric adds real-time intelligence, workload development kit

Fabric updates announced at build 2024 also include snowflake and databricks integrations and the general availability of copilot for power bi..

Senior Writer, InfoWorld |

Microsoft at its Build 2024 developer conference today announced several updates to Fabric , the company’s cloud-based suite of tools for data analytics. The additions and enhancements include a new Real-Time Intelligence module, a tool kit for customizing Fabric workflows, and the general availability of Copilot for Power BI.

Other Copilots for Fabric remain in preview.