DWYER MAST & RIGGING

The Aluminum Mast C ompany

Quality Sailboat Masts, Booms, Hardware and Rigging Since 1963

Dwyer Mast & Rigging manufactures high-quality sailboat masts, booms, hardware, and rigging. Originally founded in 1963 as Dwyer Aluminum Mast Company, the legacy continues as an OEM supplier by taking advantage of improved manufacturing methods to offer a wide range of products and services for the marine industry.

Our Services Include

Mast & Boom Extrusions // Dinghy & Keelboat Spars // Standing & Running Rigging // Hardware & Blocks // Round Tubing // OEM Supplier // Waterjet Technology // & more...

Manufacturing for the Marine Industry

Our formula for growth is simple - we never compromise with quality. By taking advantage of improved manufacturing methods and an ever-increasing volume, we have been able to maintain competitive prices and continue to provide much needed product to sailors, riggers, and boat builders.

Products & Servic es

Cont act Us

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Pay My Bill

- Customer Service

- Free Newsletter

- Give a Gift

How to Sell Your Boat

Cal 2-46: A Venerable Lapworth Design Brought Up to Date

Rhumb Lines: Show Highlights from Annapolis

Open Transom Pros and Cons

Leaping Into Lithium

The Importance of Sea State in Weather Planning

Do-it-yourself Electrical System Survey and Inspection

Install a Standalone Sounder Without Drilling

When Should We Retire Dyneema Stays and Running Rigging?

Rethinking MOB Prevention

Top-notch Wind Indicators

The Everlasting Multihull Trampoline

Check Your Shorepower System for Hidden Dangers

How Dangerous is Your Shore Power?

DIY survey of boat solar and wind turbine systems

What’s Involved in Setting Up a Lithium Battery System?

The Scraper-only Approach to Bottom Paint Removal

Can You Recoat Dyneema?

Gonytia Hot Knife Proves its Mettle

How to Handle the Head

The Day Sailor’s First-Aid Kit

Choosing and Securing Seat Cushions

Cockpit Drains on Race Boats

Re-sealing the Seams on Waterproof Fabrics

Safer Sailing: Add Leg Loops to Your Harness

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

Marine Toilet Maintenance Tips

Learning to Live with Plastic Boat Bits

- Sails, Rigging & Deck Gear

Revive Your Mast Like a Pro

Each spar section has unique signs of trouble to look for during inspection..

Unobtainium is the metal at the top of every Naval Architect’s wish list. It’s a perfect marine material; light, strong, stiff yet flexible—it’s as inert as gold, but costs only pennies per pound. Sadly, like the search for El Dorado, this metal quest remains more alchemy than chemistry.

For now, aluminum, especially the alloy 6061-T6, is the solid performer. It singlehandedly upstaged spruce as the mast material of choice, and for decades it’s done its job admirably. The alloy isn’t perfect, but by understanding its vulnerabilities, and mitigating those negative characteristics, the functional lifespan of an aluminum spar can be measured in decades not years.

Yes, carbon fiber spars are in many ways the next step forward. But for those intent on being cost effective and not in the hunt for a few tenths of a knot increase in boat speed, aluminum remains the cost effective alternative. In a future issue we’ll focus on carbon’s influence on spars, hulls, rigging, and sails.

Most metal masts are made from long, cylindrical billets of aluminum alloy. Each tube section is created using a powerful ram to force a heated billet (400-500 C) through a set of dies that squeeze and shape the billet into the cross section and wall thickness of a specific spar. Lots of lubricating release agent and 15,000 tons of ram pressure are used to reshape the malleable aluminum.

Billet residue is captured and recycled, while the tube shape undergoes quenching as it moves off on the runout table. The next stop in the line involves a process that draws (pulls) and straightens the tube section.

Once fully cooled, it goes through a T6 heat tempering process that elevates tensile strength from 35,000 to 45,000 psi. Lastly, spars can be anodized, painted, powder coated, or left uncoated. Some masts are extruded in half sections and machine-welded together lengthwise.

There are other aluminum alloys that are better suited to welded hull construction or used for metal casting purposes, but 6061-T6, containing small amounts of silicon, magnesium, and other trace elements, delivers the strength, stiffness and lightness that’s vital when it comes to making spars.

The “T6” alloy is weldable, but doing so anneals and weakens the area that’s welded. This is one of the reasons why, when splicing two sections together, a doubler is added internally that overlaps the junction. Excess heat buildup during the plug welding process that joins the sections is kept to a minimum. Some manufacturers mechanically fasten the junction using machine screws or heavy duty pop rivets.

Unfortunately, aluminum isn’t quite the sequel to tomorrow’s Unobtainium . Aluminum, like steel alloys, show a proclivity to oxidize. But in the case of most steel alloys, oxidation is an ongoing process that only reaches completion when the object in question has become an unrecognizable pile of rust.

Bare aluminum, on the other hand, reveals a very different oxidation curve. A shiny new piece of aluminum develops a speckled, gray, oxidized coating that actually becomes a protective layer, preventing further oxidation. Ironically, this means that the ugliest looking mast in the marina, that non-anodized, unpainted one with the aesthetic appeal of dirty socks, is about as well protected from further deterioration as the spar on the gold-plater with the automotive finish. This is the reason why most commercial mariners restrain from painting the deck and topsides of their aluminum workboats.

The root cause of this aesthetic injustice is the way moisture, especially salt water, finds every microscopic void or coating imperfection and causes aluminum to oxidize around voids and spread beneath the paint layer. By the time blisters appear and paint begins to flake, the sub surface is covered with aluminum oxide and starting to pit.

There are several ways to tame the effect of chloride-rich seawater. But when it comes to a failing painted surface, thorough prep work is essential. Modern epoxy primers help hold corrosion at bay, and single and two-part urethane coatings seal the surface. Hard-anodized or powder coated spars are even better protected, but cost more and are more complicated to refinish when they finally fail.

GALVANIC CORROSION

Galvanic corrosion is aluminum’s second major nemesis, and it stems from an electrical interaction rather than oxidation. Metals are rated on a galvanic corrosion scale that places less reactive (more noble) metals at one end and more reactive (less noble) ones at the other end.

Platinum, beryllium and magnesium lean against one of the bookends of this scale. Magnesium, a plentiful element, is strong and light, 35 percent lighter than aluminum, but way too reactive in the marine environment. Platinum and gold sit at the opposite bookend of reactivity and are so inert that all other metals become anodic in their presence. The metals that lie in between these are relatively ranked according to their behavior in an electrolyte such as seawater.

When it comes to marine applications, there aren’t many platinum thru hulls, but silicon bronze is a pretty good compromise between cost and corrosion resistance. It’s rank on the galvanic scale is toward the more noble end and it behaves as a cathode to less noble metals like zinc, brass, and aluminum, which become anodes in the proximity of more noble metals.

Unfortunately, when dissimilar metals are in direct contact, all it takes is a little rain or morning dew to set up a temporary galvanic cell. Salt spray finds all the nooks and crannies on a sailboat and as the water evaporates it leaves behind crystalized sodium chloride (NaCl). Each raindrop, wave splash or drop of dew rehydrates the electrolyte. And as every galvanic cell demonstrates, wherever two or more dissimilar metals are immersed, a current flows and the less noble material (anode) corrodes causing electrons to flow toward the more noble metal (cathode). The net result is pitting and eventual destruction of the anode.

This prolonged, double-barrel assault on an aluminum spar is most noticeable in areas where dissimilar metals make contact.

There’s an old superstition about putting a couple of silver or copper coins under the mast step, just before stepping the spar. It may have been a good luck charm in the days of iron men and wooden masts. But today, placing a copper penny or silver eagle in a wet mast step completes a highly reactive galvanic cell and creates a corrosion experiment of the first order. The right answer is to do everything possible to separate dissimilar metals. Putting a Delrin strip or dielectric PTFE tape between the hardware and the mast wall really helps.

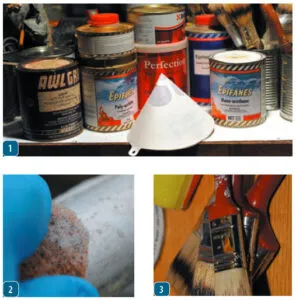

When installing larger stainless steel hardware on a mast, it’s easy to cut out a gasket from a sheet of 30 mil thick Teflon. Also be sure to use Tef-Gel or a similar dialecrtic grease or sealant on all screw threads.

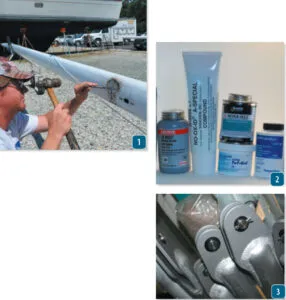

MAST INSPECTION

Once the mast has been unstepped, positioned horizontally on horses and the headsail furling gear removed, it’s time to take a close look in all the nooks and crannies where things can go wrong. I prefer a bottom up approach and group the mast into four related subsets: base, column, spreaders, and masthead. If the mast is going to be painted, postpone this DIY inspection until all the rigging and hardware has been removed. In either case, scrutinize the spar, hardware and rigging attachment points, especially where high loads are focused.

It helps to have a good magnifying glass, a pick, knife and small scraper on hand to expose and inspect oxidized areas. Place a piece of contrasting color masking tape on each point of concern as you progress toward the masthead. Once the inspection is complete, use a digital camera or smartphone to document the more serious issues. These snapshots provide a record of the location and extent of all corrosion, deep pitting and any cracks emanating from fasteners or hardware. Also record all dents or other impact damage and any sign of ongoing abrasion. Serious damage can be caused by misled wire running rigging and the cycle loading wear linked to variations in tension. Naturally, all standing and running rigging should be thoroughly inspected at this time— a topic of a future article.

AT THE BASE

Keel-stepped masts aboard many cruisers and racers are hidden below the cabin sole and reside in a wet, corrosion prone, bilge ambiance. And it’s another reason why, when a mast is unstepped, the entire support structure, step and the heel fitting deserve a close look. Check for signs of corrosion and make sure the hardware that fastens the heel fitting to the grid or other transverse and fore-and-aft support is in good shape. This structure supports compression loads and also must respond to changes in backstay tension and side loading, not to mention the shock loads of a beat to windward in heavy seas. This is also the time to do what I call spar-oscopy. Take a compact LED flashlight and tape it to the end of a long, thin PVC tube or bamboo fishing pole that will be used to look at the mast interior.

This jury-rigged light on a pole, allows you see signs of internal corrosion and gives you a chance to locate abrasion points where halyards have been misled or are rubbing on hardware. A narrow spot beam will illuminate much of the inner wall of the mast, and if the running rigging has been replaced with thin messengers and the spreader “dog bones” (cross connecting supports) have been removed, you will have a clear sight line up the spar. This is a good time to sort out any halyard overlaps.

Riggers also look for an ailment called “elephant foot.” It’s a descriptive name for the partial crumpling of the spar near the base of the mast, It’s caused by over-compression and/or a wall section that is too thin. This wrinkling is usually just above the mast step, and it indicates a condition just shy of complete failure. It can be linked to prolonged ponding to windward with excessive backstay tension and overpressuring mast jacks. In some cases a new section can be spliced into the spar. By if it’s an older mast and other significant signs of deterioration are present, it may be time to opt for a new spar. Don’t bet the farm on an “it hasn’t failed yet” assumption; hire a skilled rigger to advise on the tough calls.

At first glance, the mechanical challenge linked to stripping hardware from a mast seems rather simple. All you need are a couple of screwdrivers and you’re ready to go. Unfortunately, the gods of galvanic corrosion have placed another obstacle in the sailor’s way.

The threads of those stainless steel screws attaching hardware to base plates or to the mast wall itself have become so corroded they are likely to be screwdriver-proof. Part of the blame goes to original hardware installers, who gave little attention to coating threads with an anti-seize compound and the effect it would have on future maintenance.

So after some years or decades, when it’s time to see what lies underneath the hardware, my first step is to clean all oxidation, paint and grime away from the screw slots and make sure that the chosen screwdriver fills the entire slot. A snug fit is the goal. Then, if a good counter clockwise twist fails to elicit any rotation, it’s time to add a wrench to the screw driver and deploy a good deal more torque.

If this also fails to loosen the bugger, I go to plan B before I ruin the screw slot. Step one is to use a pick to scrape away oxidation around the screw head perimeter. The next step is to douse the area with a penetrant such as PB Blaster, CRC’s Ultra Screwloose, Knocker Loose Plus, Gasoila Free-All or a similar product (see Inside Practical Sailor blog post, “More Boat Tips: Unsticking Stuck Nuts and Bolts”).

Before once again applying torque to the problem, I spend some time using a drift pin and a small ball-peen hammer to tap each chemically soaked fastener. Afterwards I add more penetrant around each screw head. Instead of immediately reverting to a brute force approach, which more often than not leads to a broken fastener or a damaged screw slot, I let the penetrant do its thing and return the next day with my portable impact driver and assortment of screw driver bits. The small Makita impact tool applies a pulsing torque. Combined with a little penetrant and a lot of patience, I’ve found this tool to be very effective on stubborn fasteners. Screw diameters of ¼ inch or less are not hard to snap so use pulsing torque is far better than more leverage and brute force.

If the screw slot is damaged it’s time to switch gears and be ready to drill out the head of the screw and pull the hardware off the remaining stud. A stud remover fitted to a socket wrench works better than vise grips when it comes to backing out a headless screw. But it requires a half-inch or more of the screw stem to be exposed.

The secret to drilling off the damaged head of a screw involves the use of a drill bit made for stainless steel. Place it in the chuck of a low-speed drill that delivers ample torque at slow speeds. Those using a dull bit and a high-speed drill are likely to work-harden the stainless steel screw head, making it even harder to drill. Applying cutting oil that both cools and lubricates a bit will make drilling more effective.

ALONG THE COLUMN

A sailboat mast is like a long electrical fuse: one bad spot and the show is over. Critical failures are usually linked to standing rigging failures and can occur at toggle or tang attachment points, on the spar itself or at spreader tips and roots. Upper shroud tang fittings, near the masthead, need a close look. Check clevis pin holes for elongation and Tball or stem ball cups for deformation.

Sight along the open spans of the spar, where no hardware is attached. It should be free of abrasion marks and signs of halyard shackle damage. It’s surprising how many painstakingly applied paint jobs are ruined by halyard slating cause by poorly set halyards. During this part of the inspection also check exit sheaves, winch bases/pads, mast steps, the bow light, radar bracket and other attached hardware.

The gooseneck fitting and boom vang points of attachment are highstress areas and prone to developing stress cracks. Just below this union, forces converge at the mast partners, the reinforced area where a keelstepped spar passes through the deck. Check here for stress-related damage as well as corrosion issues. If you find signs of extensive pitting or stress cracks, a cosmetic repair can be more harm than help. Have a local rigger with a good reputation take a close look at what you have uncovered.

The mainsail mast track should be straight and the slugs, slides or cars that run in or on them should slide freely. Take an extra slide or car and hand test the track, identifying any points where friction increases. Problems are often caused by burred or dented metal, oxidation in an internal track or misalignment at track joints. Most of these issues are easy to resolve while the spar is horizontal and access is optimized. In-mast or in-boom furling systems each have an inspection and maintenance routine outlined by the manufacturer. Maintaining optimum reliability revolves around following these guidelines. Care should be taken to avoid keeping paint and primer from hampering track function.

Search for causes of abrasion, eliminate the dings and dents from halyard shackles by solving lead problems. And be on the lookout for hairline cracks emanating from fasteners on the leading edge of the mast. Modern spar design accounts for backstay tensioning that induces bend in the mast to adust headsail shape. This bending results in an intentional tension increase on the spar’s leading edge, adding new stress to a column already in compression. Small cracks emanating from fasteners on the leading edge of the mast can be enlarged as the mast is intentionally bowed.

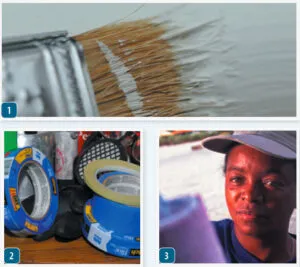

Every sailor who’s painted anything on their boat has plenty of tips to share. But when it comes to useful insider advice, pay more attention to the pros who have learned what works over many years. The good news is that although paint brand allegiance may vary, generic mast prep and painting techniques have a high degree of correlation.

When it comes to the first step in the prep process, every expert sings the same refrain. Remove the hardware if possible, especially if there’s any sign of blistering or paint failure around the edges. If there’s no sign of any corrosion at all, and the fasteners are likely to snap rather than release, carefully prep and tape around the hardware.

Sand, wire brush or sand/soda blast all areas where corrosion has pitted or left the surface covered with white aluminum oxide. Take a close look at the heel of the mast and the mast step itself. Both need to be free of corrosion and not damaged by metal loss or physical damage. The same goes for the area where spreaders, stays and shrouds attach. The masthead fitting also deserves close scrutiny. Inspect the aluminum around where the sheave axle(s) attach. A corroded aluminum masthead truck, with deterioration around the support for headstay or backstay toggles, can spell disaster. This corrosion inspection is a good time to catch pending problems.

In most cases, OEM painted spars hold up quite well, especially those that have been carefully prepped, epoxyprimed and LPU top coated. Eventually, weathering causes the gloss to disappear, but the paint retains excellent adhesive quality. If you’re facing such a challenge and there’s little or no sign of physical damage or corrosion around hardware, there’s nothing wrong with simply renewing the top coat.

In such cases, begin with a wash and/ dewax cleanup, sand with 220/320, remove dust, tape off hardware, solvent wipe and apply of two coats of the same (or similar type) topcoat, scuff-sand between coats.

However, if there are dings, scrapes or areas where corrosion has damaged the coating or areas where paint adhesion is failing, a decision must be made between spot repairs and complete mast redo. The latter involves removal of most or all of the hardware and stripping off every bit of the old paint. A spot repair approach is much less labor intensive, but if corrosion is rampant, spot repairing can be counterproductive.

During the prep process it’s essential to clean and degrease the surface before doing any sanding or other abrasive work. I prefer to use the solvent/cleaner of the paint manufacturer I’ve chosen. Clean cotton rags work best, and by meticulously wet wiping the surface you eliminate contaminants that can be forced into the substrate during sanding.

In the case of a repair and recoat effort, once the corrosion and flaking paint have been removed, feather in the adjacent painted mast surface with 60- 80 grit paper to achieve a toothy grip for the epoxy primer that follows. When doing a spot repair, this taper zone becomes an important test of one’s ability to feather an edge and hide the old to new paint junction. Seamless blending of the primer sets the stage for a successful, smooth transition spot repair. If, as you sand the boundary, the old paint continues to flake rather than allow you to feather the edge, It time to switch gears and consider removing all the paint.

An important step in painting aluminum is to get an epoxy primer on a freshly sanded and clean surface as soon as possible. When painting an entire spar, It helps if you can set up a way to hang the mast at waist level so it can be rotated in order to access all surfaces efficiently.

PRODUCT UPDATE

Interlux recommends doing the degrease wipe down with their 202 Solvent Wash prior to sanding. Then prime the spar using their InterProtect 2000E/2001E, thinned 15-20% with their brush or spray reducer. It’s a user friendly epoxy primer and easy to sand. Two coats makes the 60-80 grit sanding marks disappear. Both single-part Bright Sides and two part Perfection deliver a smooth glossy finish. The former is easier to apply and the latter is more durable and long lived.

Pettit offers a complete lineup of aluminum paint and prep products. Their approach kicks off with a solvent clean and a medium grit emery cloth sanding. When the residue has been removed, a thin coat of #6455 Primer should be applied. Two hours later, EZ Prime #6149 is applied and when it’s cured and sanded with 220 (repeat if necessary). Finish with two coats of Easypoxy.

Awl Grip recommends an initial cleaning with their surface cleaner T340 followed by a vigorous Scotchbrite scrubbing with Deoxidine and a thorough rinse to remove all residue. When dry prime with 30-Y-94 and within 3-6 hours, without sanding, apply 545 epoxy primer. Sand 220/320 and top coat with Awl Craft 2000.

If the spar was previously anodized precede the above with a 10-minute wash using a 33% solution of natrium hydroxide. Don’t let the solution dry on the spar. Immediately water-rinse and follow the prime and paint process above.

Spreader junctions are like a dangerous highway intersection, a point where competing forces interact and where there are no traffic lights to tame the flow. Rigging tension on the windward side of a sailboat cause compression loads to increase in the windward spreader(s) and decrease in the leeward spreader(s). Discontinuous standing rigging optimizes wire/rod diameter in each panel section, but it also complicates spreader tip hardware. All too often, spreader boots or a well-meaning taping effort, ends up looking like a response to an ankle injury. Even worse it creates a moisture-holding corrosion bath that enhances galvanic corrosion and oxidation. The goal is to avoid going overboard with padding and tape and making sure that water will not collect around spreader tip hardware.

Spreader bases are another realm of serious concern due to cycle loading, multidirectional forces and dissimilar metal contact. Swept back spreaders, especially those that eliminate the need for a backstay, cope with even greater loads. So when the rig is un-stepped, check how the spreader attachment was engineered. Was a doubler added to the mast wall and/ or were cutouts installed and hardware added to connect spreader pairs? In either case, corrosion in key load path areas can greatly decrease the spar’s ability to cope with the fluctuating loads. It’s no surprise that masts often break just above a set of spreaders.

AT THE MASTHEAD

Once launched, it’s hard to see what’s going on at the masthead. This means that when the spar is down it’s time to get a really close look at the mast truck and its associated fittings. Begin by disconnecting the standing rigging and checking the geometry of every hole that supports a clevis pin. The rule of thumb is: round is good, elliptical is bad. This goes for the tangs that connect upper shrouds to the spar as well as the holes in a welded aluminum masthead fitting. The loss of an upper shroud while beating to windward usually brings down the mast, so extra attention in this area is time well spent.

Carbon spar manufacturing mimics the engineering pioneered in the aerospace industry. They have become an essential component In the most competitive ranks of sailboat racing and caught on with cruising sailors who own lighter, more performance oriented sailboats.

Most spars are built on metal mandrels by carefully aligning layers of prepreg unidirectional and multi-axial carbon fiber from masthead to heel. Intermittently, a debulking process is used to squeeze the layers together, and after the laminate schedule has been carefully aligned, it’s placed in an autoclave. Here the epoxy prepreg in the carbon material becomes viscous and cures under controlled heat and air pressure. These materials are expensive, the labor is time-consuming and the quality control must be rigorous.

One of the major advantages of carbon mast building is the ability to engineer the layup to coincide with the load paths and stresses in the structure. Finite element analysis has helped identify how and where forces are transferred through the tube section. Weight is saved by only adding material where it is needed.

A cruising boat designer may opt for extra reinforcement that increases the safety factor by raising the breaking point of the material. Racing sailors have validated the performance uptick associated with carbon spars. Carbon/epoxy laminates do not suffer from corrosion but they are anything but immune to UV light. It’s one of the reasons a white primer and LPU topcoat is the sensible finish.

Minor impact damage and abrasion from poorly led running rigging is fairly straight forward to repair. But damage linked to sailing loads that cause major cracks in the laminate or interlayer delamination is another story altogether. In these cases, the spar builder or a composites shop engineer has some tough decisions to make. The big challenge is when a high-tech laminate bundle fails it’s very difficult to scarf in a new section that will handle all the loads in a manner that’s equivalent to, let alone, better than new. Some insurance companies put restrictions or higher premiums on coverage of carbon masts.

RELATED ARTICLES MORE FROM AUTHOR

Leave a reply cancel reply.

Log in to leave a comment

Latest Videos

40-Footer Boat Tours – With Some Big Surprises! | Boat Tour

Electrical Do’s and Don’ts

Bahamas Travel Advisory: Cause for Concern?

Island Packet 370: What You Should Know | Boat Review

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

Preventing and Repairing Broken Masts: A Comprehensive Guide for Sailors

Table of Contents

Introduction

Sailing is a thrilling and adventurous sport, but it is also one that comes with its fair share of risks. One of the most significant risks that sailors face is dismasting, which occurs when a sailboat’s mast breaks or falls. Disasters caused by broken masts can be dangerous and even deadly, especially if they happen at sea. In this post, we’ll discuss the causes of broken masts, how to prevent dismasting, and the steps to take when repairing a broken mast at sea.

What is Dismasting?

Dismasting is when a sailboat’s mast breaks or is removed from the boat.

What causes broken masts?

A broken mast can be caused by a variety of factors, including:

- Overloading : Too much weight on the mast or the rigging can cause it to fail.

- Fatigue : The continuous movement of the boat can cause the mast to weaken over time.

- Impact : Collisions with other boats, objects in the water, or docks can cause the mast to break.

- Corrosion : Exposure to saltwater and other corrosive elements can cause the mast to deteriorate.

- Age : As the mast ages, it may become more brittle and susceptible to failure.

How to prevent dismasting

- Proper Maintenance : Regularly inspect and maintain your mast and rigging to ensure that they are in good condition.

- Reduce Overloading : Avoid overloading the mast or rigging by reducing the weight on the boat.

- Avoid Collisions : Be vigilant when sailing and avoid collisions with other boats, objects in the water, or docks.

- Use High-Quality Materials : Use high-quality materials when building or replacing your mast and rigging.

- Avoid Exposure to Corrosive Elements : Store your boat in a dry location when not in use and avoid prolonged exposure to saltwater and other corrosive elements.

How to repair a broken mast at sea

If your mast breaks at sea, you must act quickly to prevent further damage and ensure the safety of the boat and crew. Here are the steps to follow when repairing a broken mast at sea:

- Secure the mast : The first step is to secure the mast to prevent it from causing further damage to the boat. Use any available rigging or lines to secure the mast in place.

- Assess the Damage : Assess the damage to the mast and rigging to determine the extent of the repair needed.

- Gather Materials : Gather any materials needed for the repair, such as spare parts, lines, or tools.

- Make the Repair : Make the necessary repairs to the mast and rigging. This may involve splicing lines, replacing damaged parts, or reinforcing weak areas.

- Test the Repair : Test the repair to ensure that it is secure and will hold up under sailing conditions.

- Resume Sailing : Once the repair is complete, resume sailing at a reduced speed to test the mast and rigging further.

Consequences of failing to Repair Broken Mast

A broken mast is a serious issue for sailors and can have severe consequences, especially if left unrepaired. Here follows the consequences of failing to repair broken masts and why it’s essential to take care of this issue as soon as possible.

Consequences of failing to repair broken masts

- Reduced Stability : A broken mast can cause a boat to become unstable, making it difficult to sail in rough seas or high winds. This can put the crew’s safety at risk and make the boat vulnerable to capsizing.

- Further Damage : A broken mast can cause additional damage to the boat if left unrepaired. The rigging and other parts of the boat may become damaged, which can be costly and time-consuming to fix.

- Increased Risk of Disasters : A broken mast can increase the risk of disasters, especially if the boat is unable to sail effectively. This can lead to accidents, collisions with other boats or objects, or even grounding.

- Decreased Performance : A broken mast can severely impact a boat’s performance, making it difficult to sail and navigate. This can be frustrating for the crew and may even ruin a sailing trip.

- Decreased Resale Value : A boat with a broken mast will have a decreased resale value. This can be a significant issue for boat owners who plan to sell their boat in the future.

A broken mast is a serious issue that should not be taken lightly. Failing to repair a broken mast can have severe consequences, including reduced stability, further damage to the boat, an increased risk of disasters, decreased performance, and decreased resale value. It’s essential to address the issue as soon as possible to ensure the safety of the crew, prevent further damage, and maintain the value of the boat. Regular maintenance and inspections can help prevent broken masts from happening in the first place.

When should you consult professional help for fixing your sailboat’s mast?

- Extensive Damage : If your mast has extensive damage, it’s best to seek professional help. A professional can assess the extent of the damage and determine if it’s repairable or if it needs to be replaced.

- Lack of Experience : If you lack experience with mast repairs, it’s best to consult a professional. Mast repairs require specialized knowledge and expertise that may be beyond the scope of a novice sailor.

- Safety Concerns : If you have safety concerns, it’s best to consult a professional. A professional can ensure that the mast is repaired correctly, and the boat is safe to sail.

- Time Constraints : If you have time constraints, it’s best to consult a professional. Mast repairs can be time-consuming, and a professional can ensure that the repair is done quickly and efficiently.

- Insurance Purposes : If the mast is damaged due to an accident or other incident that’s covered by insurance, it’s best to consult a professional. They can provide the necessary documentation and ensure that the repairs are done correctly and to the satisfaction of the insurance company.

Sailing is an exciting sport, but it is also one that comes with risks. Dismasting is one of the most significant risks that sailors face, but it is preventable with proper maintenance and care. If a mast does break at sea, it is essential to act quickly to prevent further damage and ensure the safety of the boat and crew. By following the steps outlined in this post, you can repair a broken mast at sea and resume sailing safely. Remember, prevention is the best course of action, and regular maintenance can help prevent dismasting from happening in the first place.

Mark Alexander Thompson

Mark Alexander Thompson is a seasoned sailor with over five years of experience in the boating and yachting industry. He is passionate about sailing and shares his knowledge and expertise through his articles on the sailing blog sailingbetter.com. In his free time, Mark enjoys exploring new waters and testing the limits of his sailing skills. With his in-depth understanding of the sport and commitment to improving the sailing experience for others, Mark is a valuable contributor to the sailing community.

Recent Posts

Lagoon vs Leopard Catamaran: Which Sailboat Is Right for You?

Introduction When it comes to cruising on the open waters, catamarans have gained immense popularity for their stability, space, and comfort. Two of the leading catamaran manufacturers, Lagoon and...

How to Determine Sailboat Weight: A Comprehensive Guide

Introduction Sailing is a thrilling and adventurous activity that has captivated humans for centuries. Whether you are a seasoned sailor or a novice looking to set sail for the first time,...

- Navigating the High Seas: A Comprehensive Guide to Sailboat Masts

Sailboat masts are the unsung heroes of the sailing world, silently supporting the sails and ensuring a smooth journey across the open waters. Whether you're a seasoned sailor or a novice, understanding the intricacies of sailboat masts is essential for a safe and enjoyable voyage. In this comprehensive guide, we will delve into the world of sailboat masts, discussing their types, maintenance, and everything in between.

Types of Sailboat Masts

Sailboat masts come in various configurations, each with its advantages and drawbacks. The two primary types are keel-stepped and deck-stepped masts.

Keel-Stepped Masts

Keel-stepped masts are the most common type, extending through the deck and resting on the boat's keel. They provide excellent stability and are suitable for larger sailboats. However, they require careful maintenance to prevent water intrusion into the boat's cabin.

Deck-Stepped Masts

Deck-stepped masts rest on the deck of the boat, making them easier to install and remove. They are commonly found on smaller sailboats and are more forgiving in terms of maintenance. However, they may offer slightly less stability than keel-stepped masts.

Components of a Sailboat Mast

To understand mast maintenance better, it's essential to know the various components of a sailboat mast. The key parts include the masthead, spreaders, shrouds, and halyard sheaves.

The masthead is the topmost section of the mast, where the halyards are attached to raise and lower the sails. It also often houses instruments such as wind indicators and lights.

Spreaders and Shrouds

Spreaders are horizontal supports attached to the mast to help maintain the proper angle of the shrouds (cables or rods that provide lateral support to the mast). Properly adjusted spreaders and shrouds are crucial for mast stability and sail performance.

Mast Materials: Choosing the Right One

Sailboat masts are typically constructed from three primary materials: aluminum, wood, and carbon fiber. Each material has its unique characteristics and is suited to different sailing preferences.

Aluminum Masts

Aluminum masts are lightweight, durable, and relatively easy to maintain. They are commonly used in modern sailboats due to their cost-effectiveness and longevity.

Wooden Masts

Wooden masts, while classic and beautiful, require more maintenance than other materials. They are best suited for traditional or vintage sailboats, where aesthetics outweigh convenience.

Carbon Fiber Masts

Carbon fiber masts are the pinnacle of mast technology. They are incredibly lightweight and strong, enhancing a sailboat's performance. However, they come at a premium price.

Mast Maintenance

Proper mast maintenance is essential for safety and longevity. Regular cleaning, inspection, and addressing minor issues promptly can prevent costly repairs down the line.

Cleaning and Inspection

Regularly clean your mast to remove salt, dirt, and grime. Inspect it for signs of corrosion, wear, or damage, paying close attention to the masthead, spreaders, and shrouds.

Common Repairs and Their Costs

Common mast repairs include fixing corroded areas, replacing damaged spreaders, or repairing shrouds. The cost of repairs can vary widely, depending on the extent of the damage and the materials used.

Extending the Lifespan of Your Mast

Taking steps to prevent damage is essential. Avoid over-tightening halyards, protect your mast from UV radiation, and keep an eye on corrosion-prone areas.

Read our top notch articles on topics such as sailing , sailing tips and destinations in our Magazine .

Stepping and Unstepping a Mast

Stepping and unstepping a mast is a crucial skill for any sailboat owner. This process involves removing or installing the mast on your boat. Here's a step-by-step guide for safe mast handling.

Step-by-Step Guide for Safe Mast Handling

- Gather the necessary tools and equipment.

- Disconnect all electrical and rigging connections.

- Use a crane or mast-stepping system to safely lower or raise the mast.

- Secure the mast in its proper place.

- Reconnect all electrical and rigging connections.

When and Why to Unstep a Mast

You may need to unstep your mast for various reasons, such as transporting your sailboat or performing extensive maintenance. It's crucial to follow the manufacturer's recommendations and ensure a safe unstepping process.

Sailboat Mast Boot: Protecting Your Mast

A mast boot is a simple yet effective way to protect your mast from water intrusion and damage caused by the elements. Here's what you need to know.

The Purpose of a Mast Boot

A mast boot is a flexible material that wraps around the mast at the deck level. It prevents water from entering the cabin through the mast opening, keeping your boat dry and comfortable.

Installing and Maintaining a Mast Boot

Installing a mast boot is a straightforward DIY task. Regularly inspect and replace it if you notice any signs of wear or damage.

Replacing a Sailboat Mast

Despite your best efforts in maintenance, there may come a time when you need to replace your sailboat mast. Here's what you should consider.

Signs That Your Mast Needs Replacement

Common signs include severe corrosion, structural damage, or fatigue cracks. If your mast is beyond repair, it's essential to invest in a replacement promptly.

The Cost of Mast Replacement

The cost of mast replacement can vary significantly depending on the type of mast, materials, and additional rigging needed. It's advisable to obtain multiple quotes from reputable marine professionals.

Yacht Masts: Sailing in Style

For those looking to take their sailing experience to the next level, upgrading to a yacht mast can be a game-changer.

Differences Between Sailboat and Yacht Masts

Yacht masts are typically taller and offer enhanced sail performance. They are often equipped with advanced rigging systems and technology for a more luxurious sailing experience.

Upgrading to a Yacht Mast

Consult with a marine professional to determine if upgrading to a yacht mast is feasible for your sailboat. It can be a significant investment but can transform your sailing adventures.

Sailboat Mast Steps: Climbing to the Top

Mast steps are handy additions to your mast, allowing easier access to perform maintenance or enjoy panoramic views. Here's how to use them safely.

Using Mast Steps Safely

Always use proper safety equipment when climbing mast steps. Make sure they are securely attached to the mast and regularly inspect them for wear or damage.

The Advantages of Mast Steps

Mast steps provide convenience and accessibility, making sailboat maintenance tasks more manageable. They also offer an elevated vantage point for breathtaking views while at anchor.

Mast Maintenance Tips for Beginners

If you're new to sailboat ownership, these mast maintenance tips will help you get started on the right foot.

Essential Care for First-Time Sailboat Owners

- Establish a regular maintenance schedule.

- Seek advice from experienced sailors.

- Invest in quality cleaning and maintenance products.

Preventing Common Mistakes

Avoid common pitfalls, such as neglecting inspections or using harsh cleaning agents that can damage your mast's finish.

Sailing with a Mast in Top Condition

A well-maintained mast contributes to a safer and more enjoyable sailing experience. It enhances your boat's performance and ensures you can rely on it in various weather conditions.

How a Well-Maintained Mast Improves Performance

A properly maintained mast helps maintain sail shape, reducing drag and improving speed. It also ensures that your rigging remains strong and secure.

Safety Considerations

Never compromise on safety. Regularly inspect your mast, rigging, and all associated components to prevent accidents while at sea.

Sailboat masts are the backbone of any sailing adventure, and understanding their intricacies is crucial for a successful voyage. From choosing the right mast material to proper maintenance and upgrading options, this guide has covered it all. By following these guidelines, you can sail the high seas with confidence, knowing that your mast is in top condition.

So what are you waiting for ? Take a look at our range of charter boats and head to some of our favourite sailing destinations .

- BOAT OF THE YEAR

- Newsletters

- Sailboat Reviews

- Boating Safety

- Sailing Totem

- Charter Resources

- Destinations

- Galley Recipes

- Living Aboard

- Sails and Rigging

- Maintenance

- Best Marine Electronics & Technology

Replacing Your Sailboat Rigging

- By Wendy Mitman Clarke

- Updated: March 23, 2020

Whether you’re buying a used sailboat that’s new to you or you’ve owned your boat for decades, the standing rigging is what keeps the mast in place, and thus requires particular attention. How do you know when it’s time to re-rig? There are some obvious answers to this one — for instance, if your wire rigging has broken strands or if it’s suffering from “candy-striping,” i.e., rust-colored streaks swirling down the wire. The latter may indicate two things: one, that it’s simply surface rust, which you should be able to polish off, or two, that as the wire was being manufactured, a strand might have picked up some contamination during the process and is compromised, which is cause for concern. A third visual indicator are cracks in swaged fittings, some of the most common end fittings for wire. Cracks are hard to see (use a magnifying glass), and sometimes marks that look like cracks can be left by the machine used to create the swage. Then there’s just age, and this factor as a reason to re-rig is more subject to a boat’s history than anything else.

“There’s a rule of thumb, but it varies rigger to rigger,” says Steve Madden, co-owner of M Yacht Services in Annapolis and the head of its M Rigging division. “My belief is that you should be replacing your sailboat’s standing rigging every 10 to 15 years.” But this time frame also is variable, depending on the boat’s purpose and use. For instance, for an offshore bluewater boat, Madden recommends 10 years, and for a serious coastal cruiser, more like 12.

“The biggest thing we like to have is the history of the boat: what kind of boat it is, how it’s been sailed and where has it been sailed,” says Jay Herman, owner of Annapolis Rigging. “That history will affect what kind of life you get out of your standing rigging.” Some insurance companies, he says, will require a re-rig if you’re purchasing a used boat that has standing rigging older than 15 years.

Either way, Jimmie Cockerill, co-owner of the Rigging Company in Annapolis, recommends that for a sailboat with wire rigging, the mast should be pulled and all fittings and wire visually inspected every five to six years. And although rod rigging may be able to last longer than wire, it too needs to be serviced every five to six years to get the most life out of it. Sticking to the 10-year rule, Madden says, means that for the most part, any corrosion or failure points will be eliminated with a re-rig.

How the rigging has been tuned is also part of a boat’s story. For instance, Madden says, he recently had a customer whose 46-foot cutter had a rigging failure at six years. The customer had had the boat re-rigged, and during a trip to the BVI, the new wire stretched. The owner didn’t adjust the rigging to compensate for the stretch for several seasons. “That was a case of not knowing that the worst thing you can do to standing rigging is have it loose on the leeward side,” he says. “Sailboat rigging very rarely fails from being overloaded. There’s such a safety margin in rigging. So you’re sailing offshore and you’re looking at the windward shroud that’s taut, and that’s not the one to worry about. It’s when the leeward side starts flopping around that you’re asking for trouble.”

Stainless steel has a finite number of cycles — essentially, movements, whether fore and aft or side to side. “The theory is that it can take 10 to 15 years of cycling, but this continual motion when it’s unloaded is what fatigues the wire,” Madden says. “There’s no real way of measuring that. Die testing won’t pick it up, and it’s rare that a wire will give you warning before breaking.”

So how often should standing rigging be replaced? For all of these reasons, most riggers agree that when your sailboat’s standing rigging approaches 15 years old, it’s a good time to consider replacing it.

Wire or Rod Sailboat Rigging?

Riggers say the question of whether to rig with wire or rod is usually fairly easily answered: Run what you brung. In other words, if your boat already has rod rigging, with all of the end fittings to terminate the rods both on deck and in or on the mast, then sticking with rod will ultimately be less expensive than making the switch to wire. Likewise, if you already have wire with fittings that accommodate your boat and mast, stick with wire. Aside from the relative cost differences between rod and wire (rod is more expensive), what also makes a switch pricey is having to significantly modify the mast to accept the different rigging.

Although rod rigging is more common on racing boats, many well-known cruising-boat builders, such as Valiant, Bristol, J/Boats and Hinckley, have rod-rigged models. The benefits of rod are less stretch, less weight, less windage, and arguably longer life than wire, because there’s less possibility for corrosion of the rod itself.

That said, some sailors prefer wire over rod for a number of reasons. First, it’s easier to fix in remote places and on your own. With a spare mechanical end fitting, wire and the proper tools, you can replace a stay pretty much anywhere. Similarly, it’s easier to find usable replacement parts far from busy ports. Wire rigging is generally less expensive and easier to handle. Finally, rod rigging requires a particular type of terminus — called a cold head — that can be fabricated only with a purpose-built machine, which only a rigging shop will have. You cannot use a mechanical fitting on rod rigging.

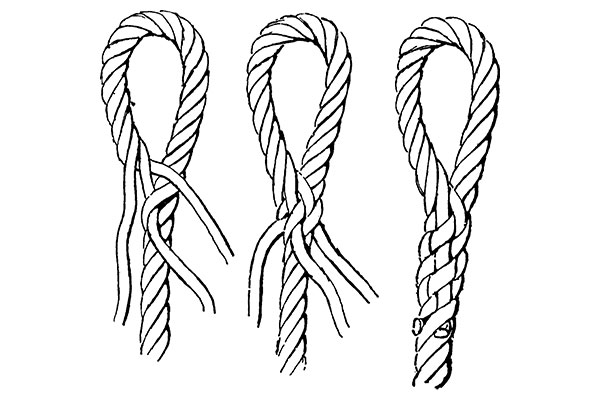

In the past, long-distance cruisers typically chose wire rigging with mechanical fittings for all of these reasons. They also would carry a piece of wire as long as the longest stay on the boat — coiled and stowed, which undeniably was sometimes easier said than done — as well as spare end fittings and the tools needed to replace a broken shroud or stay. Today, with the advent of super-strong synthetic line such as AmSteel and Dyneema, the need for that extra wire and gear is eliminated. For instance, the Rigging Company makes a spare-stay kit that can accommodate either wire or rod rigging repairs, Cockerill says. It has a synthetic stay with an eye splice, a toolless turnbuckle (the Handy Lock, made by C. Sherman Johnson), quick-release fast pins with an attached lanyard, several high-strength Dyneema loops, and even a heavy-duty zip tie to fish loops in and out of holes in a mast.

“The idea is you come on deck with this small canvas bag and make it happen,” Cockerill says. “Let’s say you ripped a tang out of the mast; you can use a Dyneema loop to create another attachment point. A smaller loop is a makeshift chainplate attachment — you can attach it to a neighboring chainplate and attach the stay to it. It’s good enough to get you to safety and someplace you can make a more permanent repair.” Riggers say very few sailors re-rig from wire to rod or the reverse, but if switching is on your mind, have a professional make a full assessment first.

There are so many variables in the system — types of end fittings, types of masts, types of attachment points — that each boat will have its own specific requirements that can affect cost. For that reason, it’s difficult to give an accurate estimate of the cost of making the switch, even for an average 40-footer.

End Fittings for Sailboat Rigging

All standing rigging, whether rod or wire, has to end in a fitting that attaches to the deck and mast. The three most commonly used types of attachments are swaged and mechanical fittings for wire, and cold heads for rod. Generally, end fittings fall into a few classes: studs, eyes, forks and hooks, each of which comes in a dizzying array of sizes and configurations. There are multiple combinations and variations: For instance, if your mast has double tangs, most likely the end fitting will be an eye — although it can be a marine eye or an aircraft eye, which differ primarily in shape. All rod rigging terminates in a cold head, which accommodates the end fitting or is encapsulated by the end fitting. This could be a marine eye, a marine fork, a T-head or a J-hook, among others.

A swaged fitting is a terminus that’s attached using a machine called a swager. It rolls the end fitting through two opposing dies and compresses the fitting on the wire so tightly that it can’t pull out. “The theory is that you’ve crushed it so tightly that all the wires inside have just merged into one solid piece of stainless,” Madden says. Swaging must be professionally done, and the result is extremely strong and generally has a long life. Top manufacturers of swaged fittings are Hayn Marine Rigging Products, Alexander Roberts and C. Sherman Johnson.

Mechanical fittings can be applied using a few common hand tools by the mechanically handy DIY sailor, which is one reason they’re popular. The two primary manufacturers of mechanical fittings presently are Sta-Lok and Petersen Stainless, which produces Hi-MOD. Both are located in the U.K., and the products are distributed in the U.S. through vendors like Hayn, West Marine, Defender, and local chandleries and riggers. Generally, they consist of either three or four parts (Sta-Lok has three; Hi-MOD has four), including a sleeve; a cone; in Hi-MOD’s case, a crown wheel; and the terminal (an eye, fork, stud, etc.). If you follow directions, they are fairly straightforward to install, although not especially easy. “The mechanical fasteners are great in that you can terminate and then look inside to be sure it’s formed correctly, so you do have a way of inspecting your work,” Madden says.

However, they generally cost more than a swaged fitting; Herman says while Hi-MOD’s newer mechanical fittings are “definitely more user-friendly to assemble, they’re twice the cost of a swaged fitting.” Some riggers will recommend swaged fittings for the mast end of the rigging and mechanical fittings at the deck level: Corrosion is less prevalent at the top of the mast, and you can more easily and regularly inspect mechanical fittings at deck level, where they’re frequently subjected to salt water

Should You Replace Your Sailboat’s Rigging Yourself?

So you’ve determined your sailboat’s standing rigging needs work. Do you hire a pro or go it alone? Good question. Yes, doing it yourself will theoretically save money. For an average 40-foot boat, Cockerill estimates about $100 per foot to re-rig with wire rigging ($4,000), as well as the round-trip cost to haul and launch the boat and unstep and step the rig (an additional $2,500 or so). By taking on the labor yourself, you’ll probably save as much as $2,000 on the re-rigging cost, he says. Madden says that cost isn’t linear, though; as you go up in size (a bigger boat needs heavier wire and larger fittings), you’ll spend more. He’d estimate more like $4,600 for a 40-foot boat, but all of these numbers depend on how much is involved: Are there furlers? What kind of end fittings? Are the chainplates sound? Depending on the answers to those questions and others, a professionally done re-rig for a 40-footer could be closer to $6,000 or more.

If you go DIY, you will be limited to mechanical end fittings unless you hire a rigger to swage your end fittings. The Rigging Company gears much of its sales to DIY sailors and is beginning an e-commerce site to cater specifically to handy individuals. But Cockerill says it quickly becomes evident whether an owner feels comfortable enough to do the work. “You should be mechanically inclined,” he says, “and the way to find that out is if I start talking all this technical jargon and you decide whether you’re suited to handle that at all.”

Additionally, a DIY sailor needs to do plenty of research, particularly when it comes to wire quality, which is something professional sailboat rigging companies watch like hawks. Although anyone can walk into a local chandlery and buy wire, that doesn’t mean the wire is of the highest quality. Marine-suitable stainless wire is called 316 grade, but even that doesn’t mean you’re necessarily getting high-quality wire. Much depends on where it is manufactured; Herman and other riggers say the best wire today is coming from South Korea through a manufacturer called KOS, making wire to military specifications. It’s imported and sold through distributors like Alps Wire Rope.

“We only sell guaranteed-content, guaranteed-process wire,” Herman says. “There are other wires out there that are cheaper, but they’re not guaranteed.”

As for sources of wire and fittings, there are many, including major chandleries and vendors, like West Marine and Defender, as well as some private riggers, like Annapolis Rigging and the Rigging Company, which will work with you to define what you need and help you source parts and materials.

One thing all the riggers I spoke with expressed emphatically was that stainless steel needs oxygen to create a fine film of oxidation that protects the metal. The fastest route to crevice corrosion is to cover the metal with plastic or leather turnbuckle covers or to coat the fittings in tape. Enough tape to cover a cotter pin suffices; otherwise, leave the metal open to the air. Likewise, if you are re-rigging your sailboatboat, use the opportunity to check your chainplates (easily the subject of another article entirely), since that’s one of the most common points of rigging failure.

Another factor in your DIY decision-making process is simple: peace of mind. “Most of my clients say to me without any prompting, ‘This is one area I feel should be done by a professional,’’’ Madden says. “You’re out there offshore and there’s a squall coming and you start worrying about the craziest of things, and you don’t want to have any unknowns.” That’s especially true of the system that keeps the mast and sails up.

Wendy Mitman Clarke is currently between passages. She’s the director of media relations at Washington College in Chestertown, Maryland, and she and her family continue to pine and plan for the day they can return to the cruising life.

- More: How To , mast , Refits , rig , rigging , sails and rigging , Upgrades

- More How To

How to Rig Everything in Your Favor

Is There a Doctor Aboard?

3 Clutch Sails For Peak Performance

It’s Time to Rethink Your Ditch Kit

Cruising the Northwest Passage

Balance 442 “Lasai” Set to Debut

A Legendary Sail

10 Best Sailing Movies of All Time

- Digital Edition

- Customer Service

- Privacy Policy

- Email Newsletters

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

Starting the Mast Step Repair

This will be the first in a series of posts about replacing the mast step on our sailboat, a 1989 Sabre 36 named Glendi. The information here is both a summary of dozens of email discussions and phone calls with Sabre owners who have already dealt with this as well as an archival of my experience fixing the issue. My hope is that this can serve as a guide for anyone who encounters this problem to save some frustration and maybe even a few boats.

Distant early warnings

Do you have a Sabre that is keeled stepped? If yes, read on. Note, this is probably more expansive than necessary as the issue does seem to be limited to certain models and years, however better safe than sorry.

The first indication that we had suffered the dreaded mast step rot, or mast step disease, was a cracked mast step plate. We noticed this when launching the boat in the Spring. Note, we had purchased the boat just a year prior and:

- I knew about the issue when we bought it

- It was inspected by a surveyor

- My broker was a fellow Sabre owner

We all missed it.

This issue hides itself very well, and although the symptoms below are early warning signs, the only way to definitively tell is to remove the mast and drill test bores. If the bores come up wet, you’re cooked. If they are dry, thank Poseidon, throw some epoxy in the hole, and go sailing.

What are all the symptoms?

- Smelly bilge water when on a tack

- Deflection of the step itself

- Visible water damage to the sole around the step, usually in front of the head

- Visible water damage to the bulkhead next to the step

- Visible water damage to the step itself

- The step bulging out on the aft side that is visible when the floorboards are removed

- Cracked mast step plate (this happens because the step is deflected)

Why? Why?!!

Everyone worth their salt knows Sabres are very well made boats. So how could this happen? Why does it happen? Well, plain and simple it is a massive design flaw, and one that could have been very easily avoided. There are differing opinions as to how the water gets into the step itself, but simply put, water comes down the mast, and spreads out over the area around the step in all directions. It is not directed properly into the bilge and over time, finds a way to penetrate the wood inside the step. Since the wood is mostly sealed, it does not rot, but over decades it gets soft and eventually will fail.

Here’s a good photo compliments of another Sabre owner that shows what lies beneath the sole and where the water acculumates.

And here’s a photo that shows just how backed up the water can get inside the bottom of the mast. The owner drilled a hole in the mast and water came flowing out.

This is the most catastrophic failure I have seen which happened while the owner was sailing and ended up in a scrapped boat. You can easily see in this photo the result of the wood softening over time and the mast eventually compressing it into a pulp.

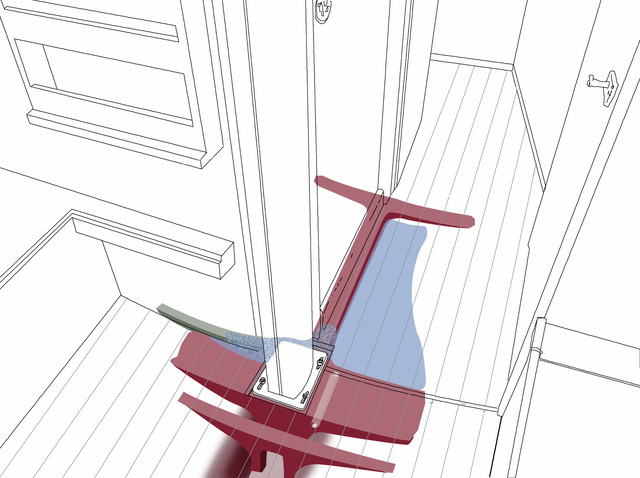

The problem could have easily been avoided is Sabre had installed a three-sided dam around the step to direct the water aft into the bilge and more effectively sealed the step. Something like this.

Not much to explain here. You will have to remove a relatively significant portion of the sole to get to the step and the two stringers that are fore and aft of the step. Some owners have chosen to replace the entire sole. This can easily double or triple the effort involved with this job. In our case the sole is in decent condition. The plywood under layer forward of the step is wet, however it is not structural and the topmost holly and teak cosmetic portion is dry. I’m going to minimize the sole I cut and try to get creative with how it gets covered up. I’m considering making a new floorboard to fit in the space so I can inspect the area in the future to ensure the issue does not happen again.

The next article will be about measuring to ensure I can place the new step, after I rip everything out, exactly where the old one was. I plan on building a jig (suggestion from a listserv member), hanging a plumb bob, and measuring to various fixed points in the boat to ensure I have a number of ways to verify that the new step is exactly where the old one was before.

Here are all the articles about the mast step issue from the Sabre owners group :

- Mast step question

- Mast step box fix

- Cabin Sole Replacement S 34-II

- Mast step disease - all models?

- Base of mast protection

- Mast step rot

- S34 # 67 Step replacement & bhead repair

Similar Posts

Sailboat Mast Base Repair

One of the first repairs I knew I would need to make to this Albin Vega was the significant amount of corrosion at the base of the mast. Over the last few weeks I was able to drop the mast, make that repair (among others) and then re-raise the mast, all in my slip using basic materials.

Before getting into that though, some news. My Albin Vega is now for sale, go here for details . I’ll explain further in a subsequent post, but I will say now that my circumnavigation is still happening.

So onto the repair. In order to lower the mast I used an A-Frame and tackle to first lift and then lower it. The materials:

- 4 x 10′ long 2×4’s

- 5 x 1/2″ lag bolts w/ nuts and washers

- Short piece of 1/4″ angle aluminum at the apex to attach tackle

- Line at the base of the legs to attach them to the stanchion bases to avoid sliding

- Line/rope which is used as stays for the A-frame, attaching to the aft/fore most cleats. My A-frame used 4 stays total

The procedure has been outlined a few times elsewhere, basically build an A-frame that extends at least ~2 feet above the spreaders (more is better) and use tackle (I used the mainsheet) to do the hoisting. I will quickly note some things I learned:

- Taller is better for the A-Frame

- Low-stretch rope used for A-Frame stays will add much peace of mind

- Using the mainsheet works, but is sketchy (more substantial tackle would add a lot of psychological comfort)

- Use tape to secure the lower shrouds in a vertical position on the chainplates to insure they don’t kink while raising

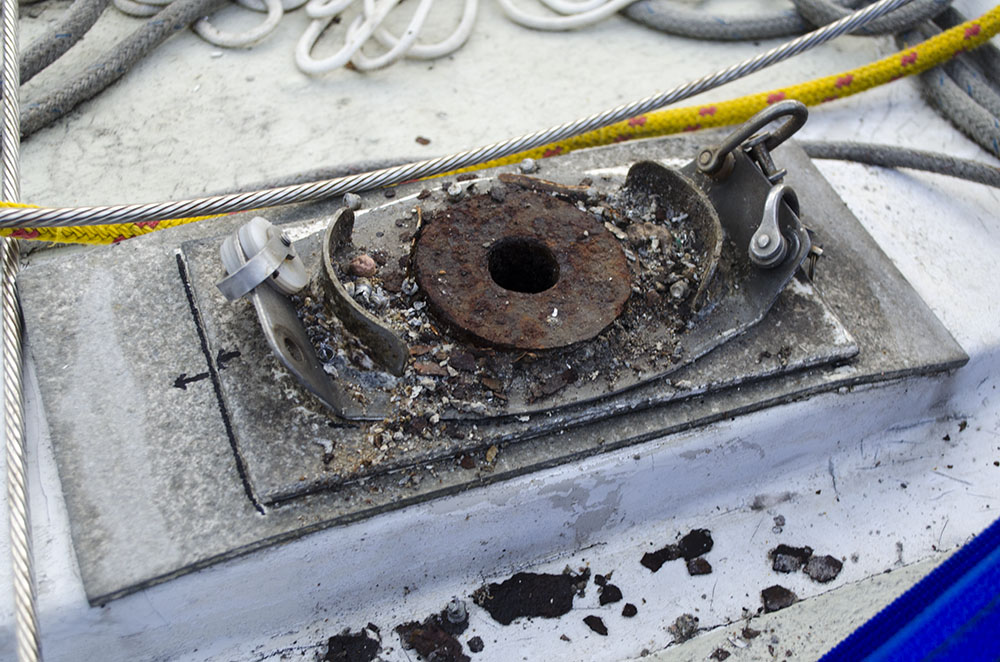

Now onto the repair itself. This is what my mast base looked like before being repaired:

Yikes! This is caused by galvanic corrosion, two dissimilar metals not playing well with one another. The mast step arrangement was also ugly:

Also yikes-worthy! Getting started, I removed that plug you see in the center. Easier said than done, to say the least. But after a day of wrestling, I did manage to get it out. This is what I was left with:

It became evident that at some point, someone put a lot of effort into reinforcing the mast step. They actually did a very good job below decks reinforcing the step. An SS plate mounted aft and aluminum angle fore, sandwiched between them is the wood bulkhead. The aluminum had slots cut into it, allowing it to be formed to the curvature of the cabin top. Ten bolts mate the three pieces. Additional wood supports then help transfer all that load down to the cabin sole. Here is what that looks like inside facing forward:

Whoever designed this did so in a way that would displace the force of the mast onto the aluminum angle, SS plate and bulkhead, which would then distribute that load across the bulkhead and down to the sole. I didn’t like the plug arrangement, but I did like the concept as a whole. So I decided to retain the features I liked and modify the ones I didn’t. Inside that gaping hole looked like this:

What I did to replace it would be better understood if I just show you. The tube I used is 3″ 6065 aluminum, 1/8″ thick:

Using the cut section of mast for the measurement, I made a spacer by encapsulating G10 in fiberglass. I gave it a large footprint to insure a widely distributed load.

I’m very pleased with the end result. Though it was a more drawn out process than some would have taken on, I don’t foresee the base being an issue again with this fix. It also looks much better than what it started as.

The most difficult and, let me be clear, very sketchy part of the operation was having the mast suspended in the air, being held up by tiny 3/16″ SS pins that seemed sure to break at any moment. Dropping and raising the mast in the slip is very doable, but heed my aforementioned advice, particularly the height of the A-Frame and stretchiness of the rope used for the stays.

Christmas in Jamaica

The old switcheroo - buying a hallberg-rassy 33.

Jacob is an incompetent sailor that expends 83% of his energy attempting not to embarrass himself. He intends to sail around the world on his 33-foot sailboat. Following years of training, Jacob has become adept at repairing things he has broken.

Related Posts

La Paz Boatyard Price Comparison

Refreshing the brightwork

The old switcheroo – Buying a Hallberg-Rassy 33

Circumnavigation by Sailboat

Hi J. I came to know of this through Cruising Forum. Well done, well crafted and well sorted through internet advice. I’m in Sydney Oz’tralia and I would be pleased to be in touch and have you stay local as you journey. Please personal message me. Fare weather and foul, best wishes. A

Thanks A! I’ll be in touch when I get nearer to Oz, feel free to send me a message anytime.

Hello J. You are most welcome in Sydney. I know this end of the Pacific. If you put chipboard into a mast base the I suggest you acknowledge with honor or correct me with facts and actual. If not, then your early reputation will be world wide announced, before you even set voyage. Not my voyage situation. Please don’t leave a maintenance death trap as you choose another vessel. Doubtfully, A.

As mentioned – it is not chip board, it is fiberglass.

Jacob, I too read about your V27 (being for sale) on ‘Cruisers Forum’, and found my self wanting to look at your web page. I think you did a very detailed mast step refit on this boat and your repair appears as seaworthy as any I have seen on any boat over the years. Lastly, you remind me of myself 40 years ago, full of interest in Life and what’s around the next bend! Never stop exploring or being willing to tackle something you’ve never done before. Now I know I’ll be logging on here to view all of your other travel logs and enjoy your creative photography as well. Don’t forget to join ‘Cruisers Forum’ as I’m sure more folks over there will come around to enjoying your travels as well! Bon Voyage! Pat

Thanks Pat! Great hearing of third party approval. Although I’ve been working on land vehicles my whole life, this boat stuff is fairly new to me…so it’s comforting that my methods meet the standards of the informed community.

It’s funny you say that [I remind you of you], as the man who sold me the new boat at such an incredible price said the same thing. Out of curiosity, how do you find life on your end of the spectrum, are you still excited and compelled to push boundaries?

You can find me over at CF, username “AmericanVagrant”. I lurk quite a bit, but am pretty selective about the conversations I join (both because they’re divisive and because I can’t proclaim to have a vast, infallible knowledge about something I’ve only been doing for a relatively short amount of time).

At any rate, hope you can find some entertainment in my journey. Be sure to stay in touch – Jacob

I want your boat, but cannot have it. Spouse doe not like her, particularly after I told her one had even done the NW passage. It is tough to be both old and stupid, but I have managed. Enjoy you venture/adventures! Best to do them before becoming youthless, but I still believe it is possible.

To prevent corrosion of mast again, could you not have used aluminum at base? Since job is done, perhaps you can use super hard rubber pad used to hold heavy compressors etc.?

Alternatively, or perhaps in addition too, you could inject base of mast, say to one foot high, with expandable polyurethane insulation. In this way condensation happening inside mast will not reach base of mast where the two different metal are close. I believe galvanic corrosion will still happened in mast if there is a continuous water film touching both metals.

Polyurethane foam is relatively easy to break up if you ever need to, to run new wiring, for example.

Instead of polyurethane foam you could add inside base of mast small plastic beads or a powdered plastic.

Leave a Reply Cancel reply

More stories, landfall in the marquesas.

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

Mast repair

- Thread starter rickv123

- Start date Oct 8, 2019

- Forums for All Owners

- Ask All Sailors

Hi. I am fairly experienced small boat sailor looking to buy a used Sonar sailboat. I recently came across a Sonar for a decent price, the only problem is that the mast had been snapped at the deck (a mooring field accident!) The mast was repaired with a replacement section placed inside the mast at the break point as a reinforcement with the the 2 original pieces (top & bottom) riveted together. Any thoughts?? Assuming a quality repair, does anyone have experince with this type of repair? Thanks, Richard

Captain Larry-DH

If the sleeve is a good fit (and of proper thickness) your repaired section is as strong or stronger than the original. It is a bit stiffer, but not an issue. Go sailing. Edit: Many new masts are shipped in sections and assembled like this at destination. Its standard in the industry.

Thank you Capt. Larry, I was told that the sleeve is a piece of a mast, from the same model, different boat. Thanks for the input. Peace.

rickv123 said: Thank you Capt. Larry, I was told that the sleeve is a piece of a mast, from the same model, different boat. Thanks for the input. Peace. Click to expand

Such repair is standard practice, but there are repairs and there are repairs. Pull strongly on the shrouds and see if there is any play at the joint, there should not be any. What they usually do is cut a section from another mast and then cut vertically a strip where the gate is leaving the section in the shape of "U" for which the sides can be compressed to fit inside the broken mast.

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

321-446-5176

Explore the world, it is a sense of well being knowing your sailboat rigging can weather the storm..

Sailboat Mast Rigging

Roller Furler Repair

Lifeline Repair

Riverview rigging llc - sailboat rigging company.

Riverview Rigging is Brevard's go to sailboat rigging company for sailboat mast repair, side stay, front stay, back stay replacement, sailing rigging, lifeline repair and replacement. We come to your location to service the needs for your vessel. Some the most common services we provide are:

- Replace sailboat standing rigging

- Repair and replace sailboat mast spreaders and electric lights.

- Repair or replace furling systems

- Lifelines, stanchions & deck hardware

- Sailboat Rigging Survey

- Architectural rigging for fences, gates, stairwell railing & more

- Custom line splicing services

- Prepare sailboat mast for shipping

Sail Repair

Line Splicing

Mast & Rigging Survey

Mast Repair & Transport

Architectural Rigging

Rigging Survey

The Worldwide Leader in Sailmaking

- Sail Care & Repair

- Sailing Gear

- Sail Finder

- Custom Sails

- One Design Sails

- Flying Sails

- New Sail Quote

- 3Di Technology

- Helix Technology

- Sail Design

- NPL RENEW Sustainable Sailcloth

- Sailcloth & Material Guide

- Polo Shirts

- Sweaters & Cardigans

- Sweatshirts & Hoodies

- Accessories

- Mid & Baselayers

- Deckwear & Footwear

- Luggage & Accessories

- Spring Summer '24

- Sailor Jackets

- Maserati X North Sails

- NS x Slowear

- Sailor Jacket

- Sustainability

- North Sails Blog

- Sail Like A Girl

- Icon Sailor Jacket

- Our Locations

- North SUP Boards

- North Foils

- North Kiteboarding

- North Windsurfing

SAIL FINDER

SAILING GEAR

COLLECTIONS & COLLAB

COLLECTIONS

WE ARE NORTH SAILS

ACTION SPORTS

Popular Search Terms

Collections

Sorry, no results for ""

THE WORLD'S BEST SERVICE

SAIL CARE & REPAIR

On Your Team, At Your Service

WE'RE HERE FOR YOU

North certified service.

Sails are a major investment, and North Certified Service experts are committed to helping you maximize their performance and lifespan. Our global network of service lofts puts North Sails service and support within easy reach no matter where you are. Every sail serviced in a North loft undergoes a thorough inspection designed to identify maintenance issues early, so they do not become major problems later on. Find your closest loft and get in touch today.

WHAT TO EXPECT?

Our expertise, customized.

With the most experienced team in sailmaking, North Sails is positioned to deliver expert repairs, maintenance, and upgrades in a timely manner. We wrote the North Manufacturing Blue Book, the industry benchmark for quality control, and we adhere to its strict standards for each and every sail that’s repaired in a North loft. Whether you need an emergency repair or annual washing and storage, our North Certified Service team will keep your sails looking their best.

BLUE BOOK STANDARDS

The Blue Book is the most comprehensive documentation of sail construction standards ever written. Our manufacturing and service sites around the globe depend on the Blue Book to build and repair a consistently excellent product. It is our clients’ guarantee of superior quality, durability, and performance in every North sail.

LOCAL LOFTS, GLOBAL SUPPORT