Published on June 2nd, 2017 | by Assoc Editor

Foiling and Foil Shapes, a Beginner’s Guide

Published on June 2nd, 2017 by Assoc Editor -->

by Mark Chisnell, Land Rover BAR The rules covering the design and construction of the team’s America’s Cup Class (ACC) boat have defined many of the parts of the boat, including the hull and crossbeams (together called the platform), and the wing shape and size. What’s left for the team’s designers and engineers to work on is principally the daggerboards and rudders, and the control systems that operate them along with the wingsail.

A lot of the technology that goes into the control systems is hidden well inside the hull, with just glimpses of the HMI (human machine interface) that the sailors use to control the board rake, wing trim and so on. The foils are on full view however, so we thought a beginners guide to ACC foil design would come in useful now the racing is approaching.

Basic Principles The foils use exactly the same scientific principles as an aircraft wing. Just as an aircraft wing will lift a plane up off the ground, the foils of an America’s Cup Class boat will lift it out of the water. Wings are foils too, called aerofoils because they work in air. The foils on the new America’s Cup boats are more accurately called hydrofoils, because they work in water.

The secret to both types of foil is the shape – aerofoils and hydrofoils use a special shape to guide the wind or water around them, and generate the lifting force to get planes and boats up in the air. Of course, the America’s Cup boats also use an aerofoil. The main wingsail works exactly the same way as an aircraft wing, it’s just rotated to stand up straight, rather than lie flat.

While an aircraft needs an engine to push the air over the wing fast enough to generate enough force to lift the aircraft up off the ground, the wingsail on the Cup boat generates force from the wind blowing past it. The harder the wind blows, the more force it makes to push the boat forward. When the boat is going fast enough, the hydrofoils will then be able to create enough force to lift the boat out of the water. This reduces resistance to the forward motion and the boat goes faster still.

There are four hydrofoils on the boat — we count the rudders at the back because they have small wings at the tips called elevators. However, the real power to keep the boat in the air comes from the hydrofoils (the daggerboards, as you will often hear them called by the sailors) and we will concentrate on these.

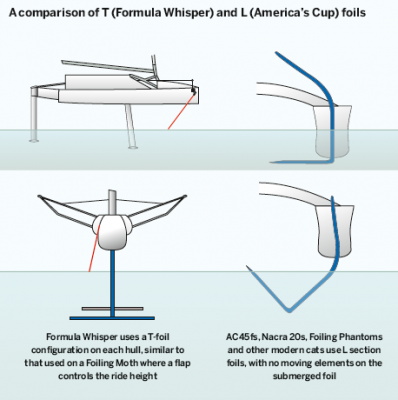

The L-Foil The L-foil is exactly that; a vertical daggerboard shaft that goes through the hull of the boat, with a single horizontal hydrofoil on the bottom, the whole thing shaped like an ‘L’. If nothing else changes, then the L-foil keeps generating lift as the boat goes faster and so the boat keeps rising, and as it rises, less and less of the daggerboard is in the water.

At the basic level, two things then happen: firstly, the boat starts to slip sideways because there is less of the vertical part of the daggerboard in the water and this makes the boat feel unstable and hard to steer. Then, ultimately, if the boat keeps rising the horizontal part of the board that is doing all the lifting will break the surface. If it does, there will be a catastrophic loss of lift and the boat will come crashing back down.

Aircraft use moving parts on the foils to control the amount of lift – trailing edge flaps — but the rules forbid these on the ACC boats, so to maintain stable flight the sailors change the rake or angle of attack of the whole dagger board (and hence the foil) to the water.

Rake If you rake the board backwards as the boat accelerates, the lift will reduce and the boat will come to an equilibrium at a steady height above the water. This is all well and good until the conditions change, maybe the wind speed goes up or down, or the boat hits some waves. When that happens the rake will need further adjustment to find the new equilibrium… until the next puff or lull when it must change again.

In the big breeze and rough water of San Francisco Bay in the 34th America’s Cup it turned out that these moments of equilibrium didn’t last very long and on occasions barely existed at all. The crew’s ability to generate the hydraulic power to change the board and wing trim was simply overwhelmed; they couldn’t achieve stable flight.

V-foil The solution was what’s called the V-foil, in which the horizontal part of the ‘L’ is angled upwards to form more of a ‘V’ shape (the angle at the bottom of the ‘V’ is called the dihedral – a dihedral of 90 degrees would define an L-foil, less than that is progressively more of a V-foil).

The V-foil uses the same principle as one of the most successful original foiling powerboats. The grand old man of 19th century innovation, Alexander Graham Bell put a couple of 350hp engines on the back of what was called HD-4 and set a new marine world speed record in 1919 of just over 70mph.

HD-4 used three ‘ladders’ of small foils, one at the front, and one each side close to the back. When the boat accelerated it started to lift out of the water, and as it lifted, one by one the ‘rungs’ of the foils would break clear of the water. As they did so the lift would decrease, and unless the boat continued to accelerate the boat would stop rising and settle at an equilibrium.

The V-foil achieves this same effect with a single foil and is used in the commercial application of fast ferries— one runs between Southampton and Cowes on the Isle of Wight, right across the Solent waters where the team train, and has done so (on and off) since 1969 – so V-foils are well understood.

When a boat equipped with a V-foil keeps rising as more lift is generated by faster speeds, both parts of the ‘V’ come out of the water together. Critically, when the ‘horizontal’ section starts to break the surface at the tip, it has the effect of reducing the lift gradually, because it doesn’t all come out of the water together. So the boat comes back down gently, working towards an equilibrium ‘ride height’ of its own accord.

It might be that it doesn’t reach this equilibrium before something else changes, but the V-foil has some inherent stability (unlike the L-foil) that doesn’t require human intervention. The shape provides a feedback mechanism to control the amount of lift and produce a more stable ride at a consistent height above the water. The downside of the V-foil is that it will generate less lift and more drag than the L-foil under the same conditions, because some of the lift generated is pushing sideways rather than up.

So one of the big questions facing the teams at the outset of this campaign was whether or not the sailors could achieve stable flight with an L-foil in the new boats and the new venue. Bermuda was a very different place to San Francisco; the winds were expected to be lighter, the water flatter and it seemed that stable flight should be easier to achieve with an L-foil under human control.

A huge amount of work has gone into foil and control system design and we now know that the answer is yes, they can – all the teams are using L-foils, often with unloaded dihedral angles of greater than 90 degrees. These angles close as the boat sails and the foil is loaded up to become much closer to, or 90 degrees.

Cant Another buzz word for the 35th America’s Cup is the cant. The cant of the board is similar to the rake, except that the bottom of the board is moving sideways across the boat, to and from the centreline, rather than backwards and forwards. When the board is canted outwards (towards the edge of the boat) it creates greater ‘righting moment’ and more power to drive the boat forwards.

Righting Moment When the wind hits a sail it creates the force to move the boat forward but it also creates a force that is trying to tip the boat over. If you have ever seen a dinghy or yacht knocked flat by a big gust of wind then you’ve already got the idea.

It’s considerably simplified, but essentially the more force that can be applied to resist the wind’s effort to tip the boat over, then the faster the boat will go, because more of the wind’s energy can be captured and applied to forward motion. The resisting force is called the righting moment and creating as much righting moment as possible is a fundamental principle of designing fast sailboats. It’s the reason that you see people leaning over the windward side when they are racing, putting bodies as far out on the windward side as possible is creating righting moment.

S-Foil Finally, there’s the question of whether the vertical part of the daggerboard should be straight or ‘S’ shaped. The curve of the S-foil could be used — like the cant — to move the bottom of the board outboard and increase the righting moment. So S-foils are more powerful, but they are also more difficult to use. The curves have to raised up and down through the bearings and internal mechanisms in the hull, and that means a lot of work to keep the friction down and the efficiency high.

Tags: AC35 , America's Cup , foiling , Land Rover BAR , Mark Chisnell

Related Posts

Kiwis reveal their America’s Cup AC75 →

Update: Youth, Women’s America’s Cup →

British AC75 arrives in Barcelona →

Swiss America’s Cup team reveal AC75 →

© 2024 Scuttlebutt Sailing News. Inbox Communications, Inc. All Rights Reserved. made by VSSL Agency .

- Privacy Statement

- Advertise With Us

Get Your Sailing News Fix!

Your download by email.

- Your Name...

- Your Email... *

- Email This field is for validation purposes and should be left unchanged.

Support our hydrofoil educational content for free when you purchase through links on our site. Learn more

[2023] Hydrofoil Yacht: The Ultimate Guide to Sailing on Foils

- November 1, 2023

- Hydrofoil Basics

Quick Answer: A hydrofoil yacht is a sailboat equipped with wing-like foils that lift the hull out of the water as it gains speed. This reduces drag, increases speed, and provides a smoother ride. Hydrofoil yachts can be retrofitted on both monohull and multihull sailboats, with different types of foils used for stability and control.

Welcome to Hydrofoiling™, where we bring you all the latest and greatest information about hydrofoil boarding. In this comprehensive guide, we’ll dive into the world of hydrofoil yachts, exploring their history, configurations, classes, and more. Whether you’re a seasoned sailor or a curious beginner, this article will provide you with expert advice and insights into the exciting world of hydrofoil yachts.

Table of Contents

Quick answer, quick tips and facts, background: the evolution of hydrofoil yachts, types of hydrofoil yachts, hydrofoil classes: from moths to ac75, hydrofoil yacht brands and models, advantages and disadvantages of hydrofoil yachts.

- Recommended Links

- Reference Links

A hydrofoil yacht is a sailboat equipped with wing-like foils that lift the hull out of the water as it gains speed. This lifting action reduces the wetted area of the hull, minimizing drag and allowing the yacht to achieve higher speeds. Hydrofoil yachts can be retrofitted on both monohull and multihull sailboats, with different types of foils used for stability and control.

Shopping Links: Check out hydrofoil yacht products on Amazon | Shop hydrofoil yacht on Walmart | Etsy hydrofoil yacht products

- Hydrofoil yachts use foils to lift the hull out of the water, reducing drag and increasing speed.

- Different types of foils, such as T foils, C foils, S foils, and L foils, are used for stability and control.

- Hydrofoil yachts can be retrofitted on both monohull and multihull sailboats.

- The International Moth class is one of the most widespread uses of hydrofoils in sailboats.

- Hydrofoil yachts can achieve impressive speeds, with some reaching over 50 knots.

Hydrofoil technology has been around for over a century, with the first patent for a hydrofoil boat filed in 1898 by Italian engineer Enrico Forlanini. Since then, hydrofoil yachts have undergone significant advancements, transforming the sailing experience and pushing the boundaries of speed and performance.

The concept behind hydrofoil yachts is simple yet ingenious. By using wing-like foils mounted under the hull, these yachts can lift themselves out of the water as they gain speed. This lifting action reduces the wetted area of the hull, minimizing drag and allowing the yacht to glide effortlessly through the water.

Hydrofoil yachts come in various configurations, each designed to optimize performance and stability. Let’s explore some of the most common types of hydrofoil yachts:

Monohull Hydrofoil Yachts : Monohull hydrofoil yachts feature a single hull and employ a “ladder” arrangement of hydrofoils. These hydrofoils typically have a dihedral angle of around 50 degrees and are complemented by a stabilizing rudder foil. This configuration provides stability and control, allowing the yacht to sail smoothly on foils.

Multihull Hydrofoil Yachts : Multihull hydrofoil yachts, such as catamarans and trimarans, offer increased stability and performance. These yachts use wider planforms, allowing for greater lift and control. Some multihulls utilize three foils, with two main forward foils providing lift and a horizontal foil on the rudder for additional control.

Hydrofoil Catamarans : Hydrofoil catamarans, also known as foilcats, combine the stability of a catamaran with the speed and efficiency of hydrofoils. These yachts can achieve impressive speeds while maintaining excellent stability, making them popular choices for racing and recreational sailing.

Hydrofoil technology has found its way into various sailing classes, revolutionizing the way we sail. Let’s take a closer look at some of the notable hydrofoil classes:

International Moth : The International Moth class is one of the most widespread uses of hydrofoils in sailboats. These single-handed dinghies feature foiling capabilities, allowing sailors to achieve incredible speeds and maneuverability. The class has seen rapid growth since 2001, with carbon fiber foils and advanced design techniques pushing the boundaries of performance.

Waszp : The Waszp class is similar to the International Moth class but utilizes aluminum foils instead of carbon fiber. This makes the Waszp more accessible to a wider range of sailors while still providing the exhilaration of foiling.

AC75 : The AC75 is a foiling monohull sailboat class used in the 2021 America’s Cup. These impressive yachts can reach speeds of up to 50 knots, showcasing the incredible potential of hydrofoil technology in the world of competitive sailing.

IQFoil : The IQFoil windsurfer class was selected by World Sailing for the 2024 Summer Olympics. These windsurfers feature hydrofoils, allowing athletes to glide above the water and achieve impressive speeds.

IMOCA 60 : Originally designed as non-foiling offshore racers, the IMOCA 60 class has embraced hydrofoil technology. These yachts now feature S-shaped daggerboard foils, providing partial foiling capabilities and enhancing performance in various conditions.

F50 : The F50 sailboat class is used in the SailGP series and is the first sailboat class to break the 50-knot barrier during a race, with a top speed of 52.2 knots. These high-performance catamarans showcase the incredible speed and agility that hydrofoil technology can offer.

Several brands have embraced hydrofoil technology, offering a range of hydrofoil yachts to cater to different sailing preferences. Here are some notable hydrofoil yacht brands and models:

Gunboat : Gunboat is a renowned brand in the world of luxury hydrofoil yachts. Their models, such as the Gunboat 68 and Gunboat 72, combine performance, comfort, and elegance, providing an exceptional sailing experience.

GC32 : The GC32 is a hydrofoil catamaran designed for high-performance racing. This foiling catamaran offers thrilling speeds and precise control, making it a favorite among competitive sailors.

AC72 and AC45f/AC50 : These hydrofoil catamarans were used in the America’s Cup, showcasing the cutting-edge technology and innovation in the world of hydrofoil yachts. These yachts pushed the boundaries of speed and performance, captivating sailing enthusiasts worldwide.

Nacra 17 and Nacra F20 : Nacra is a well-known brand in the world of multihull sailing, and their Nacra 17 and Nacra F20 models feature hydrofoil capabilities. These yachts offer a perfect balance of speed, stability, and maneuverability, making them popular choices for recreational and competitive sailing.

Hydrofoil yachts offer a range of advantages that make them appealing to sailors seeking speed, performance, and an exhilarating sailing experience. However, they also come with some drawbacks. Let’s explore the pros and cons of hydrofoil yachts:

Advantages:

Increased Speed : Hydrofoil yachts can achieve impressive speeds, thanks to reduced drag and increased lift. This allows sailors to cover more distance in less time, making hydrofoil yachts ideal for racing or simply enjoying the thrill of speed on the water.

Smooth Ride : By lifting the hull out of the water, hydrofoil yachts provide a smoother and more comfortable sailing experience. The reduced contact with the water minimizes the impact of waves and chop, resulting in a smoother ride even in rough conditions.

Improved Efficiency : Hydrofoil yachts are more efficient than traditional sailboats, thanks to reduced drag and improved lift. This increased efficiency translates to better performance and reduced energy consumption, making hydrofoil yachts an environmentally friendly choice.

Disadvantages:

Complex Design : Hydrofoil yachts require a more complex design compared to traditional sailboats. The addition of foils and the associated control systems can increase the complexity of the yacht, requiring more maintenance and potentially higher costs.

Learning Curve : Sailing a hydrofoil yacht requires a certain level of skill and experience. The handling and control of a hydrofoil yacht can be more challenging compared to traditional sailboats, requiring sailors to adapt to the unique characteristics of foiling.

Higher Costs : Hydrofoil yachts, especially high-performance models, can come with a higher price tag compared to traditional sailboats. The advanced technology, materials, and design required for hydrofoil yachts contribute to their higher cost.

How fast is the hydrofoil racing yacht?

Hydrofoil racing yachts can achieve impressive speeds, with some models reaching over 50 knots (57.5 mph or 92.6 km/h). The F50 sailboat class, used in the SailGP series, holds the record for the fastest sailboat class, with a top speed of 52.2 knots (60 mph or 97 km/h).

What does a hydrofoil do to a boat?

A hydrofoil lifts the hull of a boat out of the water as it gains speed. This reduces the wetted area of the hull, minimizing drag and allowing the boat to achieve higher speeds. The lifting action of the hydrofoil also provides a smoother ride by reducing the impact of waves and chop.

Read more about “… Hydrofoil Catamaran: The Ultimate Guide to Foiling on Water”

How fast do hydrofoil boats go?

Hydrofoil boats can reach impressive speeds, depending on their design and purpose. Racing hydrofoil yachts can achieve speeds over 50 knots (57.5 mph or 92.6 km/h), while recreational hydrofoil boats can reach speeds of 20-30 knots (23-34.5 mph or 37-55.5 km/h) or more.

Why don’t boats use hydrofoils?

While hydrofoils offer significant advantages in terms of speed and efficiency, they also come with certain limitations. The complex design and higher costs associated with hydrofoils can be prohibitive for some boat owners. Additionally, the handling and control of hydrofoil boats require a certain level of skill and experience, making them less accessible to novice sailors.

Read more about “… Why do boats not use hydrofoils?”

Hydrofoil yachts have revolutionized the sailing experience, offering increased speed, improved efficiency, and a smoother ride. Whether you’re a competitive sailor looking for the thrill of high-speed racing or a recreational sailor seeking a more exhilarating sailing experience, hydrofoil yachts provide an exciting and innovative option.

Recommended Links:

- Hydrofoil History

- Advanced Hydrofoiling Techniques

- Hydrofoil Equipment Reviews

- How Do Hydrofoils Work on Boats? 2023

Reference Links:

- Sailing Hydrofoil – Wikipedia

- Gunboat Official Website

- Nacra Official Website

- SailGP Official Website

- America’s Cup Official Website

Now that you have a comprehensive understanding of hydrofoil yachts, it’s time to set sail and experience the thrill of foiling firsthand. Whether you’re racing on the high seas or cruising along the coast, a hydrofoil yacht will take your sailing adventures to new heights. Happy foiling!

Disclaimer: The information provided in this article is based on research and personal experience. Hydrofoiling™ is not affiliated with any specific brand or product mentioned in this article. Always consult with experts and follow safety guidelines when engaging in hydrofoil activities.

Review Team

The Popular Brands Review Team is a collective of seasoned professionals boasting an extensive and varied portfolio in the field of product evaluation. Composed of experts with specialties across a myriad of industries, the team’s collective experience spans across numerous decades, allowing them a unique depth and breadth of understanding when it comes to reviewing different brands and products.

Leaders in their respective fields, the team's expertise ranges from technology and electronics to fashion, luxury goods, outdoor and sports equipment, and even food and beverages. Their years of dedication and acute understanding of their sectors have given them an uncanny ability to discern the most subtle nuances of product design, functionality, and overall quality.

Related Posts

What are hydrofoil ferry vessels well known for [2024] 🚀.

- April 12, 2024

What is a Hydrofoil Ferry? [2024] 🚢

Best hydrofoiling for beginners: a comprehensive guide [2024] ✅.

- April 9, 2024

Leave a Reply Cancel Reply

Your email address will not be published. Required fields are marked *

Add Comment *

Save my name, email, and website in this browser for the next time I comment.

Post Comment

Trending now

- Subscribe Now

- Digital Editions

Foiling technology: everything you need to know about hydrofoils

Fitting foils to powerboats is all the rage, but how do they work and why is foiling back in fashion?

What is foiling?

Foiling refers to the use of hydrofoils attached to the hull of fast boats, which provides additional lift at planing speeds – often enough to lift the hull completely clear of the water.

What is the benefit of this?

Efficiency. The enemy of fast boats is the amount of effort required to push them through the water. Planing boats go some way to addressing this by rising up over their own bow wave and skimming across the surface, but the stern sections are still immersed, creating significant hydrodynamic drag. It follows that if you can lift the boat completely clear of the water, hydrodynamic drag is only acting on the foils themselves and the sterngear that propels and steers it.

Any advantages beyond efficiency?

Lifting the boat clear of the surface can reduce the disturbance of waves, smoothing the ride, but only up to a point. It’s not just about lift though – active foils can also be used to improve stability or handling and in some circumstances, can improve efficiency even without lifting the boat.

Recommended videos for you

How do foils work.

Foils work in a similar way to aircraft wings. In simple terms, as they move through the water they deflect the flow, which exerts a force on the foil. If that force is upward, the faster they move, the greater the lift.

So why are they so much smaller than aircraft wings?

Because water is much denser than air – almost 800 times, in fact. The foils have far more to push against than aircraft wings, so don’t require the same surface area.

Is this new technology?

Far from it. Foiling technology can be traced back to 1898 when Italian inventor Enrico Forlanini began work on a ‘ladder’ foil system, obtaining patents in both the UK and the USA. He had a prototype operating on Lake Maggiore soon after. British boat designer John Thornycroft followed up with a series of scale models featuring stepped hulls and a single foil, and by 1909 had a full-scale 22ft prototype running. During WWII, the German military developed a 17-tonne foiling mine layer that was tested in the Baltic at speeds of up to 47 knots. By the early 1950s, the first commercial hydrofoil ferry was running between Italy and Switzerland and a decade later, a private hydrofoil yacht featured in the Bond movie Thunderball.

Why did they never catch on in production boating?

Traditionally, high-speed hydrofoils used large V-shaped foils that jutted out beyond the boat’s beam. This made berthing tricky and increased the draught. They were also costly to construct, vulnerable to damage and difficult to power, as the propellers of conventional shaftdrives would be clear of the water once foiling. Lastly, although hydrofoils were often more efficient than monohulls, high-speed cats could usually match the efficiency without the drawbacks.

Why are they back in the news?

Foiling technology came back into public focus when the 2013 America’s Cup contenders started to use foil-shaped daggerboards to hit speeds of more than 40 knots. Ben Ainslie’s spectacular last-gasp victory for the Oracle USA team and his subsequent BAR Land Rover Cup Challenger brought foiling to a global audience. More recently, we’ve seen the emergence of several foiling motor boats, including the SEAir RIB and the Sunreef Open 40 Power. More exciting still is the news that Princess will use an advanced Active Foil System on its new R Class superboat .

What has changed?

Technology has overcome many of the shortfalls of older systems. Simon Schofield, chief technology officer at BAR Technologies, told MBY the real game changer has been the adoption of ‘Dalí’ foils. Instead of two fixed V-shape foils, Dalí foils use four independent L-shaped blades that stick out of the hull at an angle before curving up like Salvador Dalí’s famous moustache. They are far more efficient and can be retracted, solving the berthing and draught issues. In addition, computer-controlled active systems allow the foils to be adjusted to suit speed and sea conditions. This doesn’t just improve efficiency, it can enhance the ride and handling too. When cornering, for example, a traditional hydrofoil boat doesn’t lean into the turn, making it uncomfortable for passengers. An active system can adjust each foil to induce the correct degree of lean. Modern materials also reduce drag and cavitation.

How about propulsion?

The Enata Foiler uses twin BMW diesel 320hp engines, but instead of being connected to the propellers with hefty drag-inducing shafts and gearboxes, these generate electric power which can be sent down a thin flexible cable to slender electric motors mounted on the retractable rear foils.

Lifecord – The kill cord revolution

Lifecord, a new alarmed smart kill cord that knows when you are not wearing it, ensures you’ll never forget to

Motor boat stabilisers: DMS’s new stabilisation fins

DMS's new flapping fins could become a staple for motor boats

Hybrid heaven: Adler’s 76 Suprema

Taking diesel electric propulsion to a new level, Adler's 76 Suprema may just be too innovative for the yachting marketplace

The world’s biggest electric foiling boat is coming

Sliver bullet first look – 130ft foiling boat with spaceship looks, toy of the month: pelagion hydroblade is the foiling tricycle of the future, latest videos, arksen 85 explorer tour: the ultimate long-range cruiser, sacs rebel 50 tour: the world's most luxurious rib, fairline targa tour: sensational new british sportscruiser, navan s30 & c30 tour: exceptional new axopar rival.

- Vessel Reviews

- Passenger Vessel World

- Offshore World

- Tug and Salvage World

- Maritime Security World

- Specialised Fields

- Marine Projects World

- Small Craft World

- Tanker World

- Dry Cargo World

- Boxship World

- Aquaculture World

- Trawling World

- Longlining World

- Seining World

- Potting World

- Other Fishing Methods

- Regulation & Enforcement

- Feature Weeks

- Classifieds

- Book Reviews

FEATURE | The future of hydrofoils

The following is the presentation given at the fiftieth anniversary virtual symposium of the International Hydrofoil Society (IHS) by Professor Karl Gunter Wilhelm Hoppe – naval architect at the Technical University of Berlin, Emeritus Professor at Stellenbosch University in South Africa, and director at Foil Assisted Ship Technologies.

Hydrofoils are hybrids of a planing monohull with a foil system. Hydrofoils were developed over 100 years now with some high-tech applications in the 1960s and 1980s.

The fact that the IHS still exists means there is still strong public interest in hydrofoil development even though they are not anymore in the public news.

However, some of the later hydrofoils are still in operation in certain countries and especially the Russian river hydrofoils. And yet the talk still goes around that hydrofoils are “drying out” and becoming relics that belong in museums.

Inevitably, a question has arisen after so many years have passed without virtually any new hydrofoils being built: Did we run out of experts to design hydrofoils and build them?

The clear answer is no, as hydrofoil systems have strong applications in sailboats now with extremely high tech applications reaching over 50 knots in much slower winds.

However, these are mainly sport sailboats. Why then did the hydrofoils seem to disappear?

One has to look carefully at the design of hydrofoils to find out what the real reasons of their neglect could be and find out what restraints are involved as well as the associated costs.

The two photos below show examples of hydrofoils.

There are many different foil forms and combinations with monohulls.

There are V-shape foil systems, flat type foils and deeply submerged foils; mostly all foils come in pairs for longitudinal stability. The fundamental design concept behind all hydrofoils is the idea that the foil must carry the full load weight of the craft, driving the hull out of the water and letting the foil carry all the weight with the hull being carried as deadweight, which is only there to supply sufficient buoyancy at rest and low speed.

The request for safe stability complicates the hydrofoils and this led to various ways, either to have fixed foil systems with the V-foils piercing the surface or later developments with full submerged foils and angular automatic foil control which ended up in the Boeing hydrofoils’ high-tech wave scanning system as used in aircraft – which increases costs considerably.

Another design request concerns the operation in open sea waves to let the hydrofoil platforming, which means it is not following the wave surface contour but runs on a horizontal plane. This required the foils to be deeply submerged with long struts to transmit the full weight force into the hull, which is not supposed to have any water contact when the hydrofoil is “foilborne.”

These foils and struts were of solid high tensile steel and had to have polished surfaces as the foils lose efficiency when the surfaces are rough. In seawater, especially in warm, tropical areas, foils needed to be kept clean of fouling.

All these restraints led to expensive craft and high maintenance costs.

Propulsion systems are challenging with very long propeller shafts and low OPC data. To get the hydrofoil rising at start speed, considerable power is required before it becomes foilborne.

In very bad weather only very slow speed can be used with bad efficiency and bad sea-keeping due to the low deadrise of hull. Turbine and air propulsion have low efficiency.

Hydrofoil wings at very high speed have to be extremely slender with low thickness over chord to prevent cavitation. Such wings are highly stressed and bends and struts are required to carry the ship’s weight load.

These struts create additional resistance reducing craft efficiency. They also increase ship weight and costs.

Operational constraints

At speed, hydrofoils run high above the water. This increases their tendency to experience accidents when hitting floating objects. If these objects are solid like floating containers or floating trees, the hydrofoil will come to an abrupt standstill and crash into the sea with full power on.

Several fatalities were recorded in Hong Kong with the Boeing-type Hydrofoil ferries. Even the US Navy hydrofoil patrol boat USS Tucumcari had a serious accident wherein it struck a coral reef and ended up with some crewmembers sustaining serious – but non-life-threatening – injuries.

Hydrofoils require deep harbours and they cannot navigate in smaller harbors. They are not able to approach typical sandy beaches or land on one.

A Thai company had asked us to design a Hysucraft for beach landing as their Russian hydrofoil could not approach the beach to deliver passengers. The project did not materialise as local fishermen opposed the idea.

Hydrofoils, especially those used in defence applications, are easily detected by radar due to their higher profile compared to vessels with conventional hulls.

Hydrofoils also cannot manoeuvre alongside other ships because of protruding foils. Overland transport is complicated and special trailers are needed.

Yet with all these constraints, the classic hydrofoil vessels performed exceptionally well. In 1960 to 1980, craft efficiency had no high priority and power, fuel consumption and CO2 emissions were not yet taken seriously.

Today, with climate change and CO2 reduction requirements, the pressure is on ship designers to optimise hydrofoil vessel design to ensure operating efficiency and low fuel consumption.

Also, the use of electric drive systems requires low power as batteries are very heavy still and guarantee only short ranges.

At the Stellenbosch University, RSA Marine Engineering courses were offered as early as the 1960s. The South African police and navy had requested assistance in the construction of fast patrol boats in the 10- to 15-metre range that could also operate at high speeds in extreme wind and wave conditions with short but very steep waves.

They had imported boats which did not function well and crews had to be retired already at age 40 because of damage to their kidneys and vertebrae.

We looked at offshore race boats and found that the so-called “tunnel boats” (actually split-deep-V-boats with a tunnel between two asymmetrical demi-hulls) performed best in rough sea conditions. Because of the high deadrise (24 degrees or more), they needed significantly greater engine power compared to monohull vessels.

I proposed to fit a single foil in the tunnel of such a boat at keel height to carry some of the ship’s weight more efficiently at speed. The idea was rejected. However, I tried to prove its usefulness and built a small model for towing tank tests.

Using a simple foil design with a good feel for size and profile (K-profiles) and with my experience on hydrofoil tests in the Berlin towing tank years before and also my experience on propeller design, the model was built and tested.

Expecting a 20 per cent resistance reduction, I was surprised by a 40 per cent resistance reduction. This was certainly a welcome development!

My research project at the university was called the Hysucat (hydrofoil-supported catamaran) Development, and many towing tank tests followed. Also, the theoretical development with software development for the design of Hysucat was started.

So, it was found out that the Hysucat mainfoil was considerably more efficient installed and that the interference effect increased the efficiency of hull and foil, as explained in the image below.

In the Hysucat arrangement the mainfoil is attached to the vertical tunnel walls and the foil has no tip vortex.

The foil induced downwash mass flow of hulls, and the foil is much larger than the downflow behind a free foil. The larger the induced downwash is, the more efficient the foil-hull combination will be.

This influence allowed the Hysucat to be considerably more efficient than originally expected.

Later we changed the name to Hysucraft (hydrofoil-supported craft) as we also developed foils for multihulls and even monohulls.

The fundamental design concept for Hysucraft was changed from “hydrofoils” in that the foils would only carry a partial load of the craft and relegate the stability reserves to the remaining portion of the hull that was in contact with the water surface.

So, there were no stability problems with our Hysucraft compared to “conventional” hydrofoils, wherein stability was a major problem. Hysucraft have none of the above design and operational constraints typical with hydrofoils. Further, the foils are smaller, lighter, and thinner – and therefore cheaper.

However, I want to mention two systems which give Hysucraft increased efficiency. The first are surface propeller systems with high OPC values. These propellers create strong uplift forces at the transom in the order of the thrust forces.

This has the effect as if the ship would be lighter which needs lower power. This uplift has to be incorporated in the trim calculations or it requires a certain LCG shift or foil shift.

The other propulsion system is a Servogear adjustable pitch propeller system which has a considerable higher OPC in the lower speed range as the pitch can be reduced for maximum propeller efficiency. This allows it to overcome the hump resistance at Froude number around 0.8 to 1.2 which is especially high when the Hysucraft is heavily loaded.

For extreme high speeds the propeller pitch is increased to deliver very high OPC values. Servogear systems also come with propeller half tunnels that create a significant uplift force, which in turn reduces apparent ship weight.

Hysucats can also be designed to land on sandy beaches and are easily transported on flatbed trailers.

Please compare now the typical hydrofoils with our Hysucraft in the below image, which shows the first 5.6-metre Hysucraft on the water as a manned half-sized sea model.

You can hardly see the small mainfoil amidships and the twin rearfoils for trim stabilisation near the transom. This little boat performed exceptionally well even in extremely rough seas.

We gained the Shell design award for it, a first for Stellenbosch University at the time.

The BMI-Hysucat was tested for a whole year in the sea around the cape and many experts and vessel crews from the navy and private shipping companies were invited. They checked out the Hysucat’s performance even in wave conditions that no deep-V-hull vessel owners would dare to run with speed. This was in the 1980s.

Many Hysucats were designed after this in South Africa first and soon after in Germany, Thailand, Australia, the USA, the UK, New Zealand, Brazil, Chile, Argentina, and Hong Kong among others. Including Hysucraft designs that are not our own, there must be several thousands of them on the water worldwide right now!

Ship evaluation method

During the Hysucraft development a tool was required to enable comparison of the ship’s efficiency with those of other craft. We already used a method to compare the quality of a foil wing with a planing craft by use of the aeronautical term lift/drag ratio.

In ship building the inverse is used to compare hull qualities, called the Resistance/Displacement ratio ε with R and D in Newtons it gives a dimensionless ratio.

The ship weight is usually given in t = 1000 kg but as a force has to be in newtons: D [N] = D [t] * g [m/s²] with g being acceleration of earth, 9.81 [m/s²]. In Fig. 19 the Resistance over Displacement Ratio ε is shown and tendency curves of various types of ships indicated, including hydrofoils and Hysucraft which give best efficiency for fast craft.

However, to compare the whole ship’s or boat’s quality their propulsion power Pb [kW] has to be compared.

Pb is in the horizontal direction, whereas D is in a vertical direction and the basic Power:

Pbasic is D [N] * Vs [m/s] = Pbasic [kw]

A dimensionless ratio is achieved by the ratio of:

Pb / Pbasic = Pb / (D [N] * Vs [m/s]) = EPS which is the equivalent to R/D ratio but by comparison of Powers.

The EPS turned out to be the inversed of the well known Transport Efficiency.

We determined the EPS ratios of many different ship and boat types and collected them and plotted them over the dimensionless ship speed, (the Froude Displacement number) in the second chart below, which also shows tendency curves of typical ship types. This gives a good idea how ships compare and for which speeds they are best suited.

We developed the hydrodynamic performance ratio (HPR) by dividing the Froude number by the EPS value, which is called HPR. The HPR indicates a ship’s quality by a single number. The largest number indicates a most efficient craft. The most efficient ships hardly reach a HPR of 30, which would be the most efficient craft seen.

The best hydrofoils reach about 22, USS Tucumcari about 18.3, some hovercraft about 26.3, SES Corsair about 22.54, the demonstrator craft Thunder Child II with 26.176 at top speed and 24.117 at 45 knots cruising speed, and the Alpha Yacht with 28.765 to name a few examples.

The above evaluation method gives every boat owner a tool to find out how well their ship compares to others.

Hydrofoils’ HPR data are somewhat disappointing as these might have been adversely influenced by the low OPC data of the propulsion system and by the often-used V-foils. It might have even impeded worldwide hydrofoil craft development. We thus see hydrofoils still used in certain countries but hardly any new developments in recent years.

More recently a Hysucraft hydrofoil system was designed for the 23-metre trimaran Thunder Child II of Safehaven Marine in Cork, Ireland in collaboration with Frank Kowalski.The foils improved Thunder Child II ‘s performance by nearly 35 per cent.

The World Speed Record Run for boats of 15 metres length or more was then established on August 9, 2020 on the Cork-Fastnet Rock-Cork route with average speed of 45 knots and 53 knots top speed. We are proud of this considerable result together with Frank Kowalski.

I hope that my contributions to the IHS project are well understood and that it dispells the notion of hydrofoils becoming obsolete. Hydrofoils will continue to be developed, maybe just in minor deviations from the traditional hydrofoil designs as the enormous lift-drag ratio of hulls with foils cannot be ignored in marine technology overall.

Already sailing boats are revolutionised by foil assistance and many smaller boats, especially those with electric propulsion systems, are showing improved performance.

I hope that the IHS will continue their valuable efforts and present the technological development of hydrofoil wings to improve popular understanding.

More great content as part of this month’s Hydrofoil Week right here.

Related Posts

Baird Maritime

Tags: Argentina Australia Boeing Brazil Chile Germany Hong Kong hydrofoils Hysucat HYSUCRAFT International Hydrofoil Society Ireland New Zealand Nordblitz Russia Safehaven Marine South Africa South African Navy Stellenbosch University Thailand Thunder Child II United Kingdom US Navy USA USS Tucumcari

- Previous Maersk Product Tankers completes sale of 14 vessels to CDBL

- Next VESSEL REVIEW | Seven Island Yui – New hydrofoil passenger vessel enters service between Tokyo and Oshima island

Baird Maritime , launched in 1978, is one of the world's premier maritime publishing houses.

The company produces the leading maritime new portal BairdMaritime.com , home of the world famous Work Boat World, Fishing Boat World, Ship World, Ausmarine, and Commercial Mariner sub-sites, and the industry-leading ship brokerage platforms WorkBoatWorld.com and ShipWorld.com .

Contact us: [email protected]

© Copyright - Baird Maritime

- Terms & Conditions

- Advertise with Baird Maritime

- Submit News/Leads

- AROUND THE SAILING WORLD

- BOAT OF THE YEAR

- Email Newsletters

- Best Marine Electronics & Technology

- America’s Cup

- St. Petersburg

- Caribbean Championship

- Boating Safety

The Foiling AC75

The mechatronics required to move the A75’s foils deliver precision handling and speed, and while they may look basic in form, their execution is anything but standard.

The physics of a foiling AC75 are as simple as they are complex, but envision a large windsurfing board with towering sails; there is no heavy keel to help keep it upright like a traditional sailboat. Wind blowing across the sails is the energy that essentially propels the boat forward while also making it lean over onto its side. Counteracting that heeling force on the AC75 is the boat’s subsurface horizontal foil, adjustable wings that provide lift for takeoff and steady flight.

On the opposite of the hull is the other foil arm, suspended by a massive hydraulic ram inside the boat. It’s weight helps to keep the boat balanced and upright while underway. When the boat tacks or jibes, battery-driven hydraulic rams push one foil underwater during the turn and then pulls the opposite into its up position.

Touchdowns are slow and, from what is known, take-off speed is king. Maneuverability comes next.

Under the rules of the regatta, all AC75s must meet certain dimension restrictions (length, width, weight, etc.), but the overall hull shape is left to the design team’s vision of what’s fast. There was noticeable variety in each team’s first-generation boats, common traits appeared with the second-generation designs: namely in the form of an underbody appendage that is said to capture airflow beneath the boat when foiling. Once a boat is foiling, however, the hull becomes an aerodynamic fuselage to carry the sailors controlling the boat.

Foil designs are open to development as well and that’s where the experts say the Cup will be won or lost. Teams are limited in the number of foil wings they can build for competition, but do have wide latitude to reshape them during the competition. Different wing profiles produce different results: larger wing foils get earlier liftoff in lighter winds (6.5 knots is the minimum required for racing), but come with drag. At the top of the wind range (23 knots maximum), smaller foil wings can and will be used, but here the tradeoff is speed versus control and maneuverability. The wings also have adjustable flaps and the internal mechanics of these adjustments are highly protected intellectual property.

Inside the AC75’s hull is an intricate web of hydraulic pumps, tubes, valves and rams that allow the sailors to make micro adjustments, using programmable logic controllers to manipulate the sails and foils on demand. Of the 11 crew members onboard, the division of labor is clear: the helmsman essentially steers the boat around the racecourse. The mainsail trimmer controls the three-dimensional shape of the mast and the mainsail, using a handheld controller with toggles and buttons to manipulate the sails and effectively balance the boat through every gust and lull in the wind.

The third critical crewmember in this modern-day afterguard is called the “flight controller” who uses custom controllers and software to move the big foil arms up and down, to alter their angles, and adjust the foil flaps. Essentially, these three individuals fly the boat, which leaves the eight others as pure muscle, powering the boat’s hungry hydraulic systems every time some presses a button. Nothing happens on these boats without hydraulic pressure, which is why the “grinders” will be heads-down, hammering away for 60-minute stretches on their pedestals.

- length: 75 feet – 22,86m

- max beam (width): 5m

- mast: 26,5 m

- sail area: mainsail/soft wing 145m2 – jib 80m2 – code zero 180m2

- weight: 6500 kg

- crew: 11 people

- crew weight: 990 kg

- ideal grinder weight: 105 kg

- expected speed: upwind: from 25 to 38 knots downwind: between 32 and 50 knots (one knot = 1 mile per hour = 1,852m per hour)

Exploring The Generation 1 America’s Cup 75

Naval architect Scott Ferguson examines the first-generation AC75 designs.

American Magic’s Defiant Unveiled

America’s Cup Challenger American Magic unveils its AC75 and we go in for a closer look.

The Cup’s Pro-Sailing Spinoff Takes Off

A new sailing circuit is launched, with a turbocharged fleet of America’s Cup foiling catamarans and a pool of pro sailors itching to get air time.

The Tech Behind the America’s Cup

Experts have drilled into new areas as never before for the 35th America’s Cup. While the boats might look alike, the hidden differences are critical.

Second U.S. America’s Cup Challenger Goes Live

Stars & Stripes Team USA, American flagged Challenger for the 36th America’s Cup, today released additional details outlining their boat build and design process. This

Holland in the House

At some point in the summer of 2019, Composite Builders will open the big doors on the backside of its beige 30,000 square-foot fabrication lair

Confirmed Flight for American Magic

With a productive first session on its test boat, the American Magic challenger confirms it can fly, and is quickly advancing toward the launch of its first AC75.

America’s Cup 36 Monohull Revealed

An exciting new era in America’s Cup racing has been unveiled today as the concept for the AC75, to be sailed in the 36th America’s Cup is released.

- Digital Edition

- Customer Service

- Privacy Policy

- Cruising World

- Sailing World

- Salt Water Sportsman

- Sport Fishing

- Wakeboarding

- Motorcycles

- Car of the Month

- Destinations

- Men’s Fashion

- Watch Collector

- Art & Collectibles

- Vacation Homes

- Celebrity Homes

- New Construction

- Home Design

- Electronics

- Fine Dining

- Costa Palmas

- L’Atelier

- Les Marquables de Martell

- Reynolds Lake Oconee

- Scott Dunn Travel

- Wilson Audio

- 672 Wine Club

- Sports & Leisure

- Health & Wellness

- Best of the Best

- The Ultimate Gift Guide

Boat of the Week: Meet the ‘Patriot,’ the New Lightning-Fast America’s Cup Foiling Yacht Representing the US

After being airlifted 9,000 miles from the factory, the 45-foot sailing racer exceeded designers' initial expectations by zigzagging around the auckland waterfront at insane speeds., michael verdon, michael verdon's most recent stories.

- This New 144-Foot Superyacht Has a Glassed-In Dining Room With Ocean Views

- Taking a Bow: How Yacht Makers Are Rethinking the Front End

- Airliners Are Trying Radical New Wing Designs to Improve Fuel-Efficiency

- Share This Article

Patriot , the just-launched America’s Cup racing yacht representing the United States, completed its first week of sailing last week in New Zealand . The New York Yacht Club’s representative team, American Magic, tested the potential of a design that had only been proven by computer simulation. The 75-foot navy-hulled Patriot , which just days before had been shipped by cargo plane 9,000 miles from Rhode Island, streaked across the Auckland waterfront, zigzagging on its foils, videos suggesting it reached its “sound barrier,” or top speed, of an estimated 50 knots (America’s Cup teams don’t like to talk about top speeds), or 57 mph.

Related Stories

- The 9 Best Vintage Ferraris Ever Made

- This Luxury Residential Community in Tennessee Is Opening Its Own Private Race Track

- This 29-Year-Old Is the First American Woman to Sail Around the World Solo and Nonstop

“We went off the dock thinking that if the breeze filled in, we’d have a good sail,” Terry Hutchinson, skipper and executive director of American Magic, said after the sail. “Straight away, we came into 21 knots [of wind pressure], and we were into it. Despite having a brand-new boat that we were all excited about, the whole session felt normal. That’s a great validation of our shore team and all of the work put in since we launched the Mule in 2018.”

“The Mule” was the first prototype that American Magic built to train its crew on at its facility in Pensacola, Florida, and that basic design was followed by Defender , a more complex boat that has been decommissioned since Patriot ’s arrival. Like its competitors Lunna Rossa from Italy, Britannia from the UK and the America’s Cup defender, Te Aihe from New Zealand, American Magic won’t divulge technical details about Patriot , beyond the fact its steering station is more forward than on Defender .

Patriot performed her first week of tests in front of the Auckland waterfront recently, as her team learns the idiosyncrasies of the lightning-fast foiling yacht, and designers figure out how to tweak for maximum speed. Courtesy Will Ricketson

The 75-footer is clearly fast, even out of the box, and for the next three months, designers and specialists will tweak the carbon-fiber hull and 1560-square-foot mainsail to make it even faster.

The world’s foremost sailing event, the America’s Cup has been around since 1851, though the last three Cups were more like Formula One racing, compared to the stately, slow-sailing monohulls of previous generations. The last three Cups have all been designed around foils, starting in 2013 with the AC72, and then three years ago, the boats became smaller, and much more nimble, 50-ft. catamarans that not only accelerated like an F-22 Raptor, but could nearly pivot on their own axis.

The last-generation cats were a bit too wild, so the powers that be came up with the current AC-72 class using a one-design rule where all competitors had to use common parts. The idea was to level the playing field. Organizers supply some parts of the boat, including the mast, rigging, foil-cant arms and hydraulics. The boats—16 feet wide with a crew of 11—are also built of lightweight composites because they’re designed to fly, rather than plough through the water.

While America’s Cup teams do not release top speeds, it’s estimated that the AC75 boats break the Cup’s “sound barrier” at about 50 knots, or 57 mph. Courtesy Will Ricketson

Patriot ’s foil-cant arms are also designed to move both under or outside the boat to provide the leverage to keep it upright. If it does capsize, the crews can right the boat much easier than the previous generations of foiling racers. Another new evolution for this America’s Cup is the twin-skin mainsail on the 87-foot-tall mast. The double-sail skins combine with the spar to generate the power the AC75 needs to foil. On the last two generations, the sails were much stiffer sail-wings that many non-Cup racers complained about because there was no trickle-down technology for the rest of the sailing world.

Beneath the water, Patriot also has an interesting breakthrough design. The foil-cant system uses new technology that employs a battery-driven, hydraulic-power unit to raise and lower the strong, but very heavy, foil-cant arms, that give the boat its stability and speed. As the boat changes tacks, the cant system is activated, placing one hydrofoil in the water, and lifting the other one out, where its weight becomes ballast.

Beyond the sail plan and hull design, the foil wings at the end of the arms will be another of Patriot ’s secret weapons. American Magic designers will have the ability to create any design they believe will be most effective to give the boat an edge over competitors, and the next month will be devoted to trying new shapes and sizes.

Patriot was built in Bristol, Rhode Island, by a 50-strong team and then shipped by cargo plane 9,000 miles to Auckland. Courtesy Will Ricketson

Considering the America’s Cup’s ambitious timetable, and the unexpected time pressures Covid-19 put on design and production of Patriot in Rhode Island, it’s amazing that this yacht came through so well. “This team didn’t exist three years ago, and now we have three boats built and two AC75s launched,” said Marcelino Botin, American Magic’s lead designer. “The first thing we need to focus on next is to make sure the new boat is sailed the way we want it to be sailed.”

Botin said this initial “analysis” phase will be critical to future modifications to the design. “We are all interested in knowing how the boat performs compared to our predictions and compared to our previous boat,” he says.

Hutchinson says that Patriot ’s initial performance was encouraging, especially on its first gybe. “We had a great nosedive, and that was exciting,” he said. “It was nothing that we haven’t seen or done on our other boats, and our familiarity with Patriot will increase rapidly over the coming days.”

The powerful foils allow Patriot to tack and jibe at high speeds, and to self-right if it capsizes. Courtesy Will Ricketson

Helmsman Dean Barker described the boat’s performance as “lively.”

After the America’s Cup World Series and Christmas Cup from December 17 to December 20 will come the Prada Cup Challenger Selection Series, from January 15 through February 22, 2021, where Patriot will compete against Luna Rossa and Britannia II for the challenger title. The winner of that event will then compete against Emirates New Zealand for the America’s Cup, which runs from March 6 through 15, 2021.

Read More On:

- America’s Cup

- New Zealand

- Sailing Yacht

More Marine

Forget F1. A-Lister’s Are Getting Into the SailGP Racing Game.

This Luxe 157-Foot Catamaran Lets You Explore the Galápagos With a Personal Butler

This New 79-Foot Sailing Catamaran Is Like a Pied-à-Terre for the High Seas

You Can Now Play Padel Ball on the Deck of Your Superyacht

Culinary Masters 2024

MAY 17 - 19 Join us for extraordinary meals from the nation’s brightest culinary minds.

Give the Gift of Luxury

Latest Galleries in Marine

Meet ‘Sarastar,’ the 197-Foot Superyacht With the Wildest Interior on the High Seas

Hermes Catamaran in Photos

More from our brands, exclusive: marco bizzarri leads acquisition of design company visionnaire, timberwolves can clinch west title, but ownership remains in flux, pierce brosnan, amir el-masry join agc’s biopic of boxer prince naseem hamed ‘giant,’ sylvester stallone to executive produce, greek archaeologists strike over assault, benin to stage first venice pavilion, and more: morning links for march 15, 2023, the best running water bottles according to marathoners.

The Valder Yachts designs are a development of the previous 17m and 18m asymmetric, foil assisted cats designed by Roger Hill. The hull shape best suited for a foil assisted yacht is without doubt, asymmetric. The Inner chine is brought closer to the keel line allowing for a lower foil attachment position. This places the foil deeper in the water, without compromising the hull geometry.

Speed at our core

The carbon foil design has been developed utilising the latest Computational Fluid Dynamics (CFD). This software is an analysis tool for evaluating performance and sea keeping characteristics. The Valder Yachts foil has a target speed of 50 knots, with an optimum efficiency for fuel savings in the 20 to 30-knot range.

ADVANCED CONSTRUCTIOn

The traditional method of construction and interior fitout is through the transom. This quickly becomes a congested thoroughfare for the construction team, causing a delay in the build process. At Valder Yachts, the construction of our vessels is completed with the topsides left off. This allows unrestricted access to the interior on both sides of the vessel. Using the latest 3D computer aided design and CNC machining ensures unparalleled precision, in-conjunction with modern materials and construction techniques we can construct Valder Yachts with more efficiency than traditional methods.

DESIGN FLEXIBILITY

Carbon-fibre has an incredible strength to weight ratio and can be employed in a multitude of marine applications. For example, it can be laid to form complex geometry impossible to achieve with traditional forms of boatbuilding.

LIGHTWEIGHT

Valder Yachts undergo a FEA (Finite Element Analysis) for the engineering of components. This ensures the lightest of vessels are safe for fast ocean cruising.

HIGH TENSILE STRENGTH

Carbon fibre is renowned for its tensile strength. It is one of the strongest fibres on the market.

RESISTANT TO CORROSION

Carbon is naturally resistant to oxidization. This makes it well suited to the harsh salt environment in which these boats play.

Bringing revolutionary style to yacht aesthetics

Following along the lines of the luxury car industry, Carbon Cats has taken a whole new direction when itcomes to designing luxury motor yachts in New Zealand. Clear coated exterior surfaces, exquisite leather work and sleek interior finishes with stain carbon trims. Say goodbye to bow rails, hello to free-flowing aesthetics. The traditional polished stainless brightwork has been superseded with matt black. The presentation is a snappy clean finish.

Designed for the most efficient use of space

Compared to a similar length monohull, the Valder Yacht 20m offers 20% more accommodation volume. Not only are the internal spaces larger, so to the cockpit and deck areas.

Elite Interiors

We build Valder Yachts to be bespoke with an interior that is tailored for every owner. The interior lower deck has four very comfortable staterooms with ensuite bathrooms. The full-width forward owner's cabin with king size bed is a characteristic of larger power cats. The main deck living is very 'open plan' with a seamless transition between the interior and the cockpit.

Kiwi ingenuity

Most of the work these days is centred around high-performance power cats and keeping up with current trends of foil assisted boats that push the boundaries from a speed and efficiency point of view. The team also produces a range of very efficient displacement hull designs and continue to explore design development in hull shapes, propulsion, building methods and materials.

LIGHTEN THE LOAD

For Valder Yachts to set the benchmark for speed and fuel efficiencies when cruising, a foil must be implemented to aid in reducing drag. Multiple foil designs and methods of implementation have been explored, analysing their different lift, efficiency, and pressure distribution characteristics. The foil chosen can produce 20 tons of lift at cruising speeds effectively halving the vessels displacement with a considerable reduction in wetted surface area.

EXPERIENCE THAT COUNTS

Valder Yachts has brought together the best in the business with no expense spared. Building a masterpiece requires a dedicated and committed team of artisans, who are passionate about their craft. From world leading designer Roger Hill to Scott Lane Boat Builders, one of New Zealand's most prestigious luxury power boat manufacturers.

UNBEATABLE STYLE

Valder Yachts represent a yachting renaissance, bringing back old core values coupled with modern-day trends and styling where architectural form meets craftsmanship. Soft interiors are complemented with modern materials and durable surfaces, presenting a simply timeless style.

VALDER YACHTS - GET WHERE YOU WANT TO

To give you more time for enjoying the things that you love, by delivering fast motor yachts, with a support network that you can trust.

-02.png)

Start your adventure today with Valder Yachts New Zealand, High Performance power cats that push the boundaries of yachting.

Stay up to date with our latest news and events.

- Service & Refit

- Baltic Yachts Rendezvous

FOIL-ASSISTED CRUISING

7 october 2020.

First adopted a decade ago by small racing yachts and, more recently, making the headlines as a key feature on board the latest America’s Cup boats, foil technology is typically associated with high-performance and high-speed sailing. However, Baltic Yachts’ adoption of the innovative Dynamic Stability System (DSS) from Infiniti Yachts is changing this out-dated perception and proving that the foil technology offers major benefits for the cruising sector. As testament to this, the recently delivered Baltic 142 Canova is the largest DSS foil-assisted yacht ever built, with the main aim of the technology being to improve on-board comfort as well as performance.

The average cruising sailor might dismiss a foil as complex technology that makes the boat more difficult to handle with increases in speed and sensitivity, but this is not the case at all,

explains Henry Hawkins, executive vice president at Baltic Yachts.

The deployment of the DSS foil within a cruising environment actually stabilises the boat, making sail handling and control of the boat easier and safer. One of the key benefits is the reduction in heel angle and pitching, which dramatically increases comfort levels for those on board. There are also significant performance gains to be achieved, but this is not necessarily the primary focus for employing the DSS foil on cruising yachts and certainly wasn’t on Canova.

While the development of the Infiniti-designed DSS foil has been an engineering feat for Baltic Yachts, working in conjunction with partners Farr Yacht Design, Isotop and BAR, the system has been simplified to make it as bulletproof as possible.

We wanted to ensure that something so apparently complex was made as simple and reliable as possible,

adds Roland Kasslin, head of research and development at Baltic Yachts. The system comprises a retractable foil built into the yacht just above the waterline. As the wind increases, the yacht heels and the foil is projected underwater to leeward, counteracting the heeling force and creating lift so that the yacht sails more upright.

As a result, Baltic 142 Canova is proving to be more comfortable than any comparable sailing yacht. The DSS foil package has seen reduced heel angles of between eight and 10 degrees, as well as significant pitch and heave damping, both of which dramatically enhance comfort for those on board and reduce motion and strain on the helmsman. During Canova’s first long-distance passage, the yacht crossed the Bay of Biscay in 50-plus knots of wind and big seas, but the deployment of the foil made the passage comfortable for all on board.

For inexperienced sailors, heel angle is one of the aspects about large sailing yachts that people fear the most and can make life on board untenable – a heel angle of 18-plus degrees on a 43m yacht with a 9m beam creates a considerable sloping deck, says Hawkins. This significant reduction in heel angle means that moving around the boat is much easier and safer, making long passages more enjoyable.

Another benefit of the additional stability that the DSS foil provides is that less keel weight is required, which has the knock-on advantages of less required sail area, draught and overall displacement. Therefore, a lightweight hull in carbon composites ideally suits the system – Canova displaces just over 145 tonnes lightship. For this reason, it is important that the decision to include a DSS foil is made right at the beginning of a project, as retrofitting the system is not always the optimal solution.

While Canova is the largest yacht to be fitted with a foil by a significant amount, the scope of the DSS is boundless.

The technology is scalable as long as there is the technical space for it, and the bigger the boat, the more possibility there is for that,

advises Kasslin. It would also be a weight-conscious decision: if you are deploying a foil then the boat needs to be able to achieve a certain speed in order to overcome the natural drag that the foil will produce.

Thanks to its outside partners and, crucially, one brave and forward-looking client, Baltic Yachts has pushed the boundaries of foil technology and proven its benefits to the superyacht industry. The industry is naturally cautious towards innovation and therefore adoption of foil-assisted cruising has taken time. However, the success of the DSS foil on board Canova is changing attitudes and, combined with the increasing use of foils on racing yachts, the technology is set to become more popular in the cruising sector, with Baltic Yachts paving the way.

MORE ABOUT US

DYNAMIC STABILITY SYSTEM

Aided by her DSS foil package, Baltic 142 Canova is proving herself to be faster and more comfortable than any...

Baltic 142 Canova

This highly innovative long distance cruising yacht is notable for being the first superyacht to be fitted with a transverse...

We’re constantly updating our website to bring you news of launchings, new commissions and Baltic inspired innovation.

Professional BoatBuilder Magazine

The efficiency of a foiling powercat.

By Dieter Loibner , Mar 13, 2020

Matanzas Watercraft’s founder, Jan Brandt, in his office with a rendering on the wall and the prototype of the Matanzas 29 foiling powercat peeking through the shop door.

Motivated by his own boating experience and America’s Cup foiling technology, a startup builder launches the Matanzas 29, a new breed of powercat for fishing and cruising.

Wherever Jan Brandt goes, a constant companion since his childhood days in Hamburg, Germany, is his passion for watersports. Competitive swimming, surfing, waterskiing, fishing, scuba diving, sailing, you name it, he’s done it—and still does. No surprise, then, that Brandt is also deeply involved with boats, not just using them but also designing and building them. His latest project is a 29 ‘ (8.8m) foil-assisted planing cruising power catamaran designed for twin outboards from 60 hp to 90 hp. Last fall, construction was far advanced as Brandt prepped for finishing, outfitting, and getting the boat ready for sea trials off St. Augustine, Florida, where he set up shop as Matanzas Watercraft LLC.

Inspired by the Sliver 29, a catamaran designed for fishing and weekending, built by SuperCat in South Africa , Brandt defined specifications that suited his own use patterns and his home port in St. Augustine. “I am looking to build a day-use cat for fishing offshore waters but also capable enough to make the run to Bimini and Abacos on a calm summer morning,” his design brief reads. Also on the list: sufficient load capacity for three to four people for day use and provisions for a couple to cruise for a few days; a range of 200 nm on one tank; and a cruising speed of 20 to 25 knots. Brandt: “I need to deal with a 2–3 ‘ [0.6m–0.9m] chop and Atlantic Ocean swells. While an open cockpit with center console and hardtop is totally sufficient, a head and dry storage for gear with maybe just enough space for a bunk for two would be awesome.” Since crab or lobster pot buoys are not much of a concern in Florida, Brandt explored the idea of foil assist to reduce power requirements and improve seakeeping. However, he was adamant about the ability to safely beach the cat and limit overall beam to 9.1 ‘ (3m) to keep the trailering permits manageable.

The Matanzas 29 plywood/carbon prototype has wave-piercing bows with a positive rake and peaked decks that shed water quickly. The bows’ fine entry flattens out toward the stern to encourage planing, even when operating without foils.

He did some preliminary design work himself, but when the project got serious he consulted with Bieker Boats of Anacortes, Washington. Principal Paul Bieker served as the lead designer of the Oracle America ’s Cup sailing team and was instrumental in developing the outrageously fast 72 ‘ (22m) foiling catamarans that ushered in a foiling revolution following the 2013 Cup on San Francisco Bay. Bieker now applies variations of the foiling concept to pleasure craft, most recently with an innovative 53 ‘ (16m) sailing catamaran intended for racing and weekend cruising (see “ Fledging the Eagle ,” Professional BoatBuilder No. 182) and now with Brandt’s foiling powercat.

The basic idea behind foiling is maximizing efficiency while curbing the need for big engines, a notion that has yet to find footing with production boatbuilders. Brandt: “I’m not interested in boats over 25 ‘ [7.6 m] running 250- or 300-hp twin motors. I’ve been doodling around for a year on the idea, spent more time on the hullform, and when I decided to pull the trigger on building one, that’s when I contacted Paul to help me finalize the design, incorporate some of the design criteria and requirements, and make it work from an engineering perspective. He helped crystallize the hull shape and get the details fleshed out.”

Foiling Tech Trickle-Down

A former racing sailor who campaigned a Mini 650, Brandt met Bieker in 2010 while cruising the waters of Puget Sound. He ran his own environmental consulting firm in Seattle and also took up boatbuilding. First came stitch-and-glue kayaks, but soon he graduated to the PT Skiff, an 18′ (5.5m) kit boat by Port Townsend Watercraft designed by Bieker and Russell Brown. With Brown’s encouragement Brandt designed and built the cedar-strip carbon composite Syhoya , a handsome 21 ‘ (6.4m) weekend cruiser powered by a 60-hp Evinrude E-Tec outboard for cruising Puget Sound and beyond.

Previously, Brandt designed and built Syhoya, a 21’ (6.4m) weekender with a 60-hp outboard for cruising the coastal waters of the Pacific Northwest.

In Brandt’s painstakingly clean and organized workshop a 10-minute drive from his house in St. Augustine Beach, Bieker’s plans laid out on the workbench and the prototype of the Matanzas 29 under construction showed how personal predilection, boating experience, and exposure to innovative design ideas informed his choices. For a simple boat that aims to maximize efficiency and minimize power requirements, the design process was complicated. Some salient features, like the combination of planing hulls with wave-piercing bows and the foil arrangement most commonly associated with fast sailing cats, seem a bit counterintuitive at first, but Brandt explained the underlying thinking.

He wanted to minimize the fatigue of the acceleration/deceleration forces when running the steep chop of St. Augustine Inlet during an outgoing tide, “letting the bows do the work,” rather than endure slamming, Brandt explained. “That’s when we combined the wave-piercing hulls with the foil assist in order to get away from larger engines while still being able to carry the displacement we need, all the things we added that were part of my criteria—the fish boxes and the scuba gear. All that weighs quite a bit, [but we wanted] to manage that with reasonably small motors. That’s how we got to wave-piercing bows and the foils.” Load-carrying capacity, especially at speed, is another reason he decided against displacement hulls.

Passengers can ride on the main deck, under the hardtop, or on the “rumble seat” forward.

Why plywood/composite instead of carbon-reinforced plastic construction, which would have further minimized weight? Brandt reasoned it was less complex and costly for a prototype that has to establish proof of concept and test the nascent market for foiling powerboats. Tooling up for a production run is his goal. The thin plywood—okoume 6mm/1⁄4 “ for the topsides, 9mm/0.35 “ for the bottom—is sheathed in E-glass, a laminate schedule of 200-g (5.9-oz) and 300-g (8.95-oz) layers inside and out. Turn Point Design in Port Townsend cut the kit, based on design files it received from Bieker Boats. “That worked perfectly. We have had zero issues with the wood fit,” Brandt recalled. “Every puzzle joint fit the first time.” For the foam-core portions of the boat, he used 20mm (0.79 “ ) Divinycell H80 sandwiched between multiple layers of regular-modulus carbon woven roving of 5.9 oz 0°/90°, and 2×2 twill weave of the same weight, which conforms well to complex 3D shapes. For taping and to reinforce high-load areas, Brandt applied 400 g/m2 (11.8 oz/sq yd) of 45° double biaxial carbon and 9 oz/sq yd (305 g/m2) unidirectionals.

The entire wet deck, measuring 18 ‘ x 10 ‘ (5.49m x 3.05m), was vacuum-bagged with the foam core and three layers of carbon fiber on each side, laid up in various directions. That’s a large piece to build in a compact workspace, so he tackled it first and then stored it against the wall to make room for hull construction. Florida’s warm, humid climate imposes its own demands on working with resins, which ideally are catalyzed and processed in an ambient temperature around 65°F (17°C). Brandt planned to get the big parts done during the cooler time of year, turning on the air-conditioning if necessary and starting at 3 a.m. Doing “the large areas of the hull, we had three layers of glass on the bottom, so running that over 30′ [9.14m] in one shot, even just hand layup, gets challenging, because the initial pot cures before you have the last layer on.” That’s a herculean task for one, but he had help from his wife, Tonya, and then hired some neighborhood kids to do some sanding.

This angle shows the square sterns, the cutouts for the fuel hoses and steering lines, the carbon-reinforced main deck, and the storage boxes.