Yachting Monthly

- Digital edition

Best marine diesel engines: a buyer’s guide

- Sam Fortescue

- September 24, 2021

Modern marine diesel engines may look very similar to the large, noisy, oily chunks of iron of yesteryear, but a lot has changed under the bonnet, says Sam Fortescue

An inboard engine is a critical part of any boat, whether you're a purist who only motors when safety demands, or if you'd rather get into harbour in time for last orders. The chances are you also rely on the engine for battery charging. Credit: WorldFoto/Alamy Stock Photo

Best marine diesel engines: the new tech making inboard engines cleaner, more efficient, lighter and more reliable

Once referred to as the ‘auxiliary’ engine , your boat’s inboard diesel is now so much more than just a helping hand.

Not only is it central to your boat’s ability to manoeuvre safely into tight marina berths, it also allows you to keep up average speeds and make the tidal gate before it closes, charges the batteries that run the ever-expanding suite of entertainment and navigational tools aboard, and keeps the beers cold and showers warm.

Despite visual similarities to the noisy models of yesteryear, modern marine diesel engines are cleaner and more efficient, lighter and more reliable. And they are increasingly interactive.

If you’re considering re-powering your boat, here are some of the key features to look out for.

Marine Diesel Engines: Emissions

Tighter regulation in Europe has been forcing engine manufacturers to reduce the harmful emissions generated by their equipment.

In the marine sector, that means complying with the 2013 Recreational Craft Directive, known as RCD 2, and often with the EPA Tier 3 requirements in the USA.

Though most manufacturers anticipate further tightening in the future, there is nothing yet on the cards for marine diesel engines in the leisure sailing sector.

The focus on reducing emissions has resulted in a better understanding of the combustion process inside the cylinder.

A key pollutant, nitrous oxide, is formed at higher combustion temperatures, so one advance has been to reduce those temperatures.

A mechanical system, like this Beta Marine engine, offers ease of maintenance. You don’t need a laptop to reset the electronics

Increasing the swept volume of the cylinder theoretically creates more power, because there is room to burn more fuel each cycle, but if you keep fuel consumption the same, the diesel generates less heat in combustion.

Another area of development has been around the fuel injection system.

A lot has been written about the desirability and reliability of so-called common rail versus mechanical injection for marine diesels.

As Andrew Growcoot, CEO of Beta Marine puts it: ‘The benefits of a mechanical system [are] simplicity and ease of maintenance. One doesn’t need a laptop to reset the electronics ; a mechanical system is safe and will not power down at the wrong time.’

Beta Marine is a British marine diesel engine supplier that uses a Kubota block, and has no intention of introducing the technology any time soon on sub-100hp engines.

The same is true of France’s Nanni and Spain’s Solé, who both supply good, reliable diesel marine engines to the sailing market.

Hedley Beavis of Solé distributor Engines Plus says research to find a common rail injection system has been delayed by COVID-19.

‘It is not an easy task finding a reliable common rail engine but also at a reasonable price for the marine market,’ he adds.

But while common rail injection makes your engine reliant on an electronic control unit for precise high-pressure fuel injection and makes it more susceptible to poor quality fuel, this widely used technology can also offer significant benefits in terms of power and fuel consumption.

Continues below…

Diagnose and fix marine diesel engine problems

Tim Bartlett explains how you can diagnose some common marine diesel engine problems, and fix most of them

White diesel: is it worth converting from red?

Duncan Kent examines the implications of switching from red to white diesel and what you can do to avoid fuel…

How to: troubleshoot your marine diesel fuel system

One of the most common causes of a marine diesel engine not starting is a fuel problem. If you have…

How to avoid diesel bug

Diesel bug can clog filters, wreck engines, corrode fuel tanks, and leave you powerless at sea. Ben Sutcliffe explains how…

Plus, it’s quieter and produces less vibration.

That’s because the diesel is injected as a huge number of tiny droplets, greatly increasing the surface area for better combustion.

Common rail injection is usually found on more powerful engines – Volvo Penta uses the system in its D3 engine and above, which starts at 110hp.

But Yanmar took a bold step in 2018 when it launched a new 40hp unit with electronic fuel injection. The 3JH40 is still the smallest marine diesel engine with this technology.

‘Through common rail technology, the 3JH40 offers minimal fuel consumption and exceptionally low noise and emission levels, exceeding EPA Tier 3 and EU RCD Tier 2 emission regulations for virtually smoke- and odour-free operation,’ says marketing manager Sander Gesink.

‘People don’t want to have the smell of diesel onboard making them seasick.’

The demand for more plentiful electrical power on board boats has led engine manufacturers to increase the output of their alternator systems.

Where a typical alternator on a 30hp engine might have been around 50A two decades ago, they are now often in excess of 100A.

So, for example, even Volvo Penta’s entry-level D1-13 engine packs a meaty 115A alternator with its own built-in charging regulator, for optimal battery charging.

The 50hp D2-50 offers the same alternator, as well as the option of expanding output with a pulley take-off for a second alternator.

Even Volvo Penta’s entry-level D1-13 engine packs a meaty 115-amp alternator with a built-in charging regulator

Beta Marine’s 43hp engine comes with a 70A alternator as standard, but can accommodate upgrades to 120A or 175A alternators, as well as a second 175A alternator for really hefty charging.

It is worth noting, however, that many of these alternators remain fairly basic bits of kit with an inflexible charging regime.

That’s one reason that Yanmar has worked with Mastervolt on its 150hp-plus 4LV engines to develop a secondary charging option in addition to the on-board 130A unit.

Using the Alpha III charge regulator, that alternator will put exactly the right charge into the battery bank on a three-step regime that works regardless of the RPM by varying the field current going into the alternator.

Units on smaller, older marine diesel engines can easily be retrofitted with a regulator, such as Sterling Power’s Pro Reg.

Interactive marine diesel engines

It used to be that marine diesel engines would buzz along in the background unless they overheated, in which case you were treated to an ear-splitting alarm from the control panel.

They still do sport their own dedicated warning lights which ping on if oil pressure drops or the temperature rises above a safe 80-90ºC.

But with the growth of instrumentation on board, and the development of fast, bi-directional networks, engine manufacturers have had to up their game.

That means enabling the engine to put data into your NMEA2000 instrument network about its speed, temperature and oil pressure, as well as many other potential parameters on more complex systems.

‘Captains just want to see their engine performance and details on their MFDs,’ says Yanmar’s Gesink.

Steyr’s unique monoblock marine diesel engine starts at 75hp. The MO 4-CYL uses a two-stage unit injection system with the benefits of high-pressure fuel without the requirement for electronic control

As a common rail injection engine, Yanmar’s 3JH40 already has the electronics necessary to connect directly to the boat’s NMEA2000 instrument network, as well as the VC10 electronic throttles and other controls via a J1939 CAN bus.

These include the YD42 smart panel display, which will toggle through engine data such as load percentage and engine hours, as well as standard navigational data like depth and wind speed.

‘Direct connectivity to NMEA and J1939 CAN-bus networks has been purpose engineered into the 4LV range, allowing future-proofed integration to any multifunction bridge display. Same counts for the 3JH40 and the rest of our common rail engine range,’ adds Gesink.

While 110hp-plus Volvo Penta marine diesel engines – the D3 upwards – have been built since 2006 with a proprietary Electronic Vessel Control system, its smaller D1 and D2 marine diesel engines were given a hybrid solution.

This Mechanical Diesel Interface (MDI) is a black box fitted to the side of the exhaust manifold, where heat and vibration have made it somewhat temperamental.

Without the MDI, the engine simply won’t run, although it is quite straightforward to bypass.

Volvo sells an Easy Connect adapter that plugs into the J1939 socket on the MDI and feeds its data out onto a NMEA 2000 instrument network, allowing it to be visualised on the plotter or other displays.

Volvo’s Easy Connect app allows you to monitor engine-specific data over Bluetooth on smart devices

Other manufacturers also offer products that can do this.

Volvo offers dedicated instruments to show fuel level, temperature and voltage if you want it.

It also produces its own glass bridge touchscreen displays from 7in to 24in, although this will mainly appeal to the powerboat market.

More interesting for sailors is Volvo’s Easy Connect app available for smart devices, which allows you to monitor engine-specific data over Bluetooth thanks to the Easy Connect adapter.

Other engine manufacturers have adopted a more agricultural approach.

Beta Marine, for instance, has worked with market-leading sensor firm Actisense to build a module that plugs into the wiring loom that runs between the engine and the control panel, and feeds data into the NMEA 2000 network.

It only works with one of Beta’s more expensive C and CW Deluxe control panels, and requires a bit of splicing in of wires.

Solé also offers an NMEA 2000 converter to get analogue data from the engine into your digital instrument network.

You still need a dedicated control panel, but the SDC2000 kit even allows the engine’s alarms to be transferred to your MFD.

It is compatible with all Solé diesel engines since 2008.

France’s Nanni uses a similar NMEA adapter, but also offers a dedicated interactive display to enhance its control panel – available for all engines above 21hp.

There is a small 4in model, and larger 7in and 9in display built around Raymarine technology, with charting, radar and CHIRP sonar support.

The choice is yours

Every owner will make up their own mind on common rail injection.

It looks like the way of the future, judging by the automotive sector, but critics point out that poor quality fuel and the need for maintenance in out-of-the-way places weigh in favour of mechanical fuel systems.

It depends whether you’ve got far-flung cruising in mind, or whether you plan to stick to home waters.

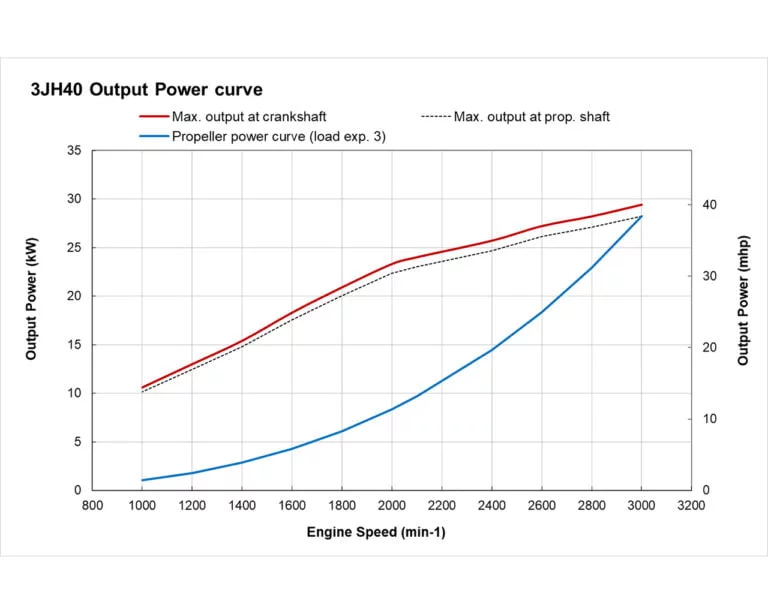

Weigh up your priorities. The Yanmar’s fuel consumption is certainly better than the competition.

But the Beta offers one of the best torque curves, equating to more usable power at cruising revs.

Thinking about going electric? Click here

Either way, don’t be tempted to overpower the boat, as marine diesel engines are most efficient at around 80% of their revs.

If you want the engine to feed data onto the network, it’s best to know from the outset, so the engineer can hook the whole thing up.

That said, it’s hardly a complex job, although the necessary kit amounts to several hundred pounds in the aftermarket.

If you’re looking to re-power, the key criteria will always be the space available, and access to filters, impellers and freshwater systems for maintenance .

While there’s broad consensus about hydrogen being the fuel of the future, the path to fuel-cell propulsion is distinctly unclear.

In the meantime, alternative fuels may play an increasing part in the energy mix for combustion engines: methanol or ammonia can be stored as liquids and mixed with diesel in a combustion engine.

There are challenges to overcome, not least the nitrous oxides produced when ammonia burns, but there is research time going into just that.

Shipbuilder CMB is working with manufacturers of bigger engines to make the design tweaks to run on dual fuels; focused on the injection system.

A more immediate possibility is the use of hydrogenated vegetable oil ( HVO ) or gas-to-liquids (GLT).

HVO is essentially biodiesel and can be made from waste cooking oil, while GLT is made from natural gas and is said to burn more cleanly than diesel.

‘The advantage of mechanical injection systems is that the engine can take advantage of using low- emission alternative fuels, such as HVO and GLT, without alterations to the engine,’ adds Beta Marine CEO Andrew Growcoot.

Marine Diesel Engines: A buyer’s guide

Volvo penta d2-50.

Volvo Penta D2-50: Easy to get NMEA data from the engine

Volvo has an odd gap in its engine line-up between the 28hp D1 and the 50hp D2, which exist in both shaft and saildrive formats.

The D2 marine diesel engines run at 3,000rpm, which is pretty standard for this power rating.

In general, slower rotation makes for less noise and vibration. Both series use inline injection and feature the MDI electronic interface which has suffered from reliability problems in the past.

On the plus side, the interface makes it easy to get NMEA data out of the engine and onto your instrument network. It also opens up a good range of snazzy remote displays.

Volvo’s ergonomic electronic controls won’t work with the D2 engine, however. They are only compatible with the EVC marine diesel engines that run on common rail injection.

Volvo has excellent, if expensive, global support.

- Power: 51hp (37.5kW) crankshaft

- Cylinders: 4

- Displacement: 2,200cc

- Fuel consumption at max rpm: 11.5lt/hr

- Dry weight: 249kg

- D2-50: £9,360

- Dealers: www.volspec.co.uk ; www.goldenarrow.co.uk

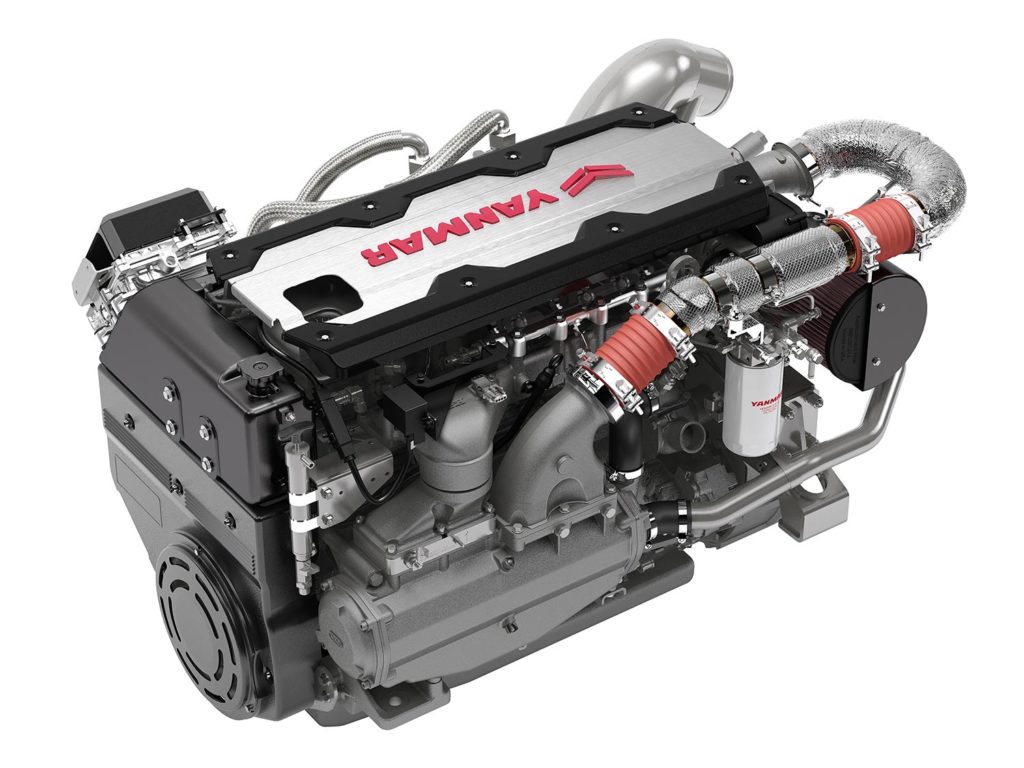

Yanmar 3JH40

Yanmar 3JH40: An award-winning 40ho engine

With a power output rated at 40hp, this hugely successful, award-winning engine was launched in 2018.

Its key feature is the common rail injection system which Yanmar has introduced with claims that it reduces smoke and odour to nearly nil.

This is due to the more complete combustion of the diesel fuel when injected under high pressure.

It also operates at a relatively low 3,000rpm, which makes it quieter than faster-spinning engines, and reduces vibration.

Yanmar has developed a series of digital controls for its engines. The VC10 and VC20 electronic throttles make data such as engine loading available on the network.

There are also dedicated displays like the YD42, which has a full-colour screen. Otherwise, a £350 analogue-to-digital converter will get your engine data onto the NMEA 2000 network.

There’s a saildrive option, which costs some £2,500 more than the shaft alternative.

Yanmar engines are also very well supported with servicing.

- Power: 40hp (29.4kW)

- Cylinders: 3

- Displacement: 1,642cc

- Fuel consumption at max RPM: 8.8lt/hr

- Dry weight: 192kg

- www.barrus.co.uk

Beta 43: Excellent, mid-range torque for its rating

Beta Marine diesel engines are based on the solid Kubota block, and represent good value, no-frills performance.

Painted a distinctive red colour, they offer flexible installation thanks to a good range of options.

This makes them well suited to repowering in tight corners.

Though the design is constantly being improved, this is a traditional mechanical engine with the minimum of electronic gimmickry.

It offers excellent mid-range torque for its rating.

The standard control panels are steadfastly analogue, although a NMEA2000 converter is available to get limited engine data onto the network.

A new digital display panel is now available, with a standard loom input and a NMEA 2000 output.

Reliable and well supported with spares, and readily serviced, these are good engines that are sold worldwide.

- Power: 43hp

- Displacement: 1,999cc

- Fuel consumption at max RPM: 9.3lt/hr

- Dry weight: 238kg

- www.betamarine.co.uk

Nanni N4.43

Nanni N4.43: Low rpm makes for a quieter unit

Nanni, a French-Italian brand, is well represented in the UK by AR Peachment. These distinctive blue marine diesel engines have helped make Nanni the world’s third largest marine engine supplier.

The engines are fairly traditional, with indirect mechanical fuel injection, natural aspiration and water-cooled exhaust manifold. Relatively low RPM makes for a quieter unit.

The N4.43 is in fact a de-rated version of the larger 50hp unit.

Being a mechanical engine, the N4.43 relies on an NMEA adapter to get engine data onto the network.

Though controls remain analogue, the N4.43 is compatible with a series of Nanni digital displays which start at 4in.

Support at the leisure end is not as widespread as bigger brands, but as it’s based on a Kubota engine block, it should be easy to find a competent mechanic.

- Power: 43hp (29.4kW)

- Displacement: 2,197cc

- Fuel consumption at max RPM: 10.3lt/hr

- Dry weight: 228kg

- www.peachment.co.uk

Solé Mini-44

Solé Mini-44: Decent torque at mid range

Spain’s Solé produces a very wide range of diesel marine engines, and the Mini-44 is aimed at yachts in the 10-12m LOA range.

Sam Fortescue is a freelance marine journalist and former magazine editor who sails a Sadler 34, which has taken his family from the Caribbean to the Baltic

It looks cheaper than the competition, but Solé’s model is to quote a fixed price and not engage in the inevitable discounting of the other brands.

This is the smallest four-cylinder unit the company builds, giving quieter running but greater fuel consumption at top speed.

Though rated 42hp, it has a smaller capacity and has to work harder to achieve it.

For that reason it compares better against 38hp models.

A purely mechanical engine, it relies on cam-driven indirect fuel injection and produces decent if not outstanding torque at the mid range.

Available with an impressive range of gearboxes, including saildrive fittings, the Mini-44 is a very flexible engine with lots of options.

A very expensive converter (SDC2000 – £800) is available to transfer the engine’s analogue data into digital signals for your NMEA 2000 network.

But the control panel options, although very attractively styled, remain resolutely analogue.

Solé has decent global support, naturally focused on Europe and the Spanish-speaking world.

- Power: 42hp (30.9kW)

- Displacement: 1,758cc

- Fuel consumption at max RPM: 10.4lt/hr

- Dry weight: 175kg (w/o gearbox)

- www.enginesplus.co.uk

Enjoyed reading Best marine diesel engines: a buyer’s guide?

A subscription to Yachting Monthly magazine costs around 40% less than the cover price .

Print and digital editions are available through Magazines Direct – where you can also find the latest deals .

YM is packed with information to help you get the most from your time on the water.

- Take your seamanship to the next level with tips, advice and skills from our experts

- Impartial in-depth reviews of the latest yachts and equipment

- Cruising guides to help you reach those dream destinations

Follow us on Facebook , Twitter and Instagram.

Best Small Marine Diesel Engines: Compact Powerhouses for Your Boat

Embarking on marine adventures calls for reliable power sources, and choosing the best small marine diesel engines is paramount for smooth sailing. In this comprehensive guide, we delve into the top-performing options available in the market to assist you in making an informed decision. From compact yet powerful engines suited for smaller vessels to efficient models ideal for sailboats or motorboats, our reviews cover a range of top-rated products tailored to meet various marine needs. Whether you are a seasoned sailor or a novice enthusiast, finding the best small marine diesel engine is essential for enhancing your boating experience.

We’ll cover the best small marine diesel engines later in this article. Meanwhile, check out these related products on Amazon:

| # | Preview | Product | |

|---|---|---|---|

| 1 | |||

| 2 | |||

| 3 | |||

| 4 | |||

| 5 |

Last update on 2024-07-08 at 03:10 / Affiliate links / #ad / Images from Amazon Product Advertising API

Table of Contents

Understanding Small Marine Diesel Engines

Small marine diesel engines are compact, reliable power sources used in various watercraft, including boats, yachts, and small commercial vessels. These engines are designed to provide efficient propulsion and generate electricity for onboard systems. Typically ranging from 10 to 400 horsepower, small marine diesel engines offer a balance between size, power, and fuel efficiency.

One of the key advantages of small marine diesel engines is their durability and longevity. Built to withstand the harsh marine environment, these engines are known for their robust construction and ability to operate effectively in challenging conditions. This reliability makes them a popular choice among boat owners and commercial operators who require dependable performance on the water.

Small marine diesel engines are also valued for their fuel efficiency, consuming less fuel compared to gasoline engines of similar size. This not only reduces operating costs but also minimizes the environmental impact of marine vessels. Additionally, diesel fuel is more readily available in many parts of the world, making these engines a practical choice for long-distance cruising and international travel.

Overall, small marine diesel engines offer a cost-effective solution for propulsion and power generation in a wide range of marine applications. With advancements in technology, these engines continue to improve in terms of performance, emissions control, and onboard integration, ensuring they remain a popular choice among boaters and marine enthusiasts.

5 Best Small Marine Diesel Engines

01. yanmar 3ym30.

The Yanmar 3YM30 is a reliable and powerful marine diesel engine that is perfect for sailboats and small yachts. With a compact design and smooth operation, this engine delivers impressive performance while remaining fuel-efficient. Boaters can rely on the 3YM30 for smooth and quiet sailing experiences on the water.

Featuring advanced technology and durable construction, the Yanmar 3YM30 is known for its low emissions and low maintenance requirements. Boasting a reputation for longevity and dependability, this engine is a popular choice among boat owners looking for a solid and efficient power source for their vessels.

02. Volvo Penta D1-30

Featuring a robust 30 horsepower engine, the Volvo Penta D1-30 is a powerful and reliable marine propulsion system. Designed for sailboats and yachts up to 40 feet in length, this engine offers smooth and efficient performance on the water. Its compact size and low weight make it easy to install and maintain, while the advanced fuel injection technology ensures optimal fuel efficiency and reduced emissions.

Boasting a reputation for durability and longevity, the Volvo Penta D1-30 is a popular choice among boaters looking for a dependable and high-performing engine. With its quiet operation and minimal vibration, this engine provides a comfortable and enjoyable boating experience, whether cruising along the coast or navigating open waters.

03. Nanni N3.30

Nanni N3.30 is a reliable and efficient marine diesel engine that delivers impressive performance. Its compact design makes it versatile for various boat sizes, providing smooth operation and easy maintenance. The engine’s power output is suitable for small to medium vessels, ensuring a steady and dependable propulsion system.

With its durable construction and low fuel consumption, the Nanni N3.30 is a cost-effective choice for boat owners seeking long-term value. The engine’s quiet operation and minimal vibration enhance the overall boating experience, making it a preferred option for those who appreciate a smooth and comfortable ride on the water.

04. Mercury Diesel TDI 3.0

With the Mercury Diesel TDI 3.0, power and efficiency seamlessly come together. This marine engine delivers strong performance and exceptional fuel economy, making it a standout choice for boat owners. Its advanced technology ensures smooth operation and reliability even in challenging conditions, providing peace of mind on the water.

Boasting impressive torque and horsepower, the TDI 3.0 offers the perfect balance of power and control. Its low emissions and quiet operation enhance the overall boating experience, while its easy maintenance requirements add convenience for users. The Mercury Diesel TDI 3.0 is a top-tier option for those seeking a high-performing and dependable marine engine.

05. Beta Marine 25

With its compact design and reliable performance, the Beta Marine 25 is a standout choice in the marine engine market. Boasting a power output of 25 horsepower, this engine is ideal for both leisure and commercial vessels. The Beta Marine 25 is known for its fuel efficiency and low emissions, making it environmentally friendly without compromising on power.

Users commend the quiet operation of the Beta Marine 25, as well as its smooth running and easy maintenance. Its durability and robust build ensure a long service life, making it a top pick for boat owners seeking a dependable engine for their marine needs.

Top Reasons to Invest in Small Marine Diesel Engines

Small marine diesel engines are essential for a variety of marine vessels, including small boats, yachts, and fishing vessels. These engines provide reliable power for propulsion and electrical systems, making them a crucial component for boaters and sailors alike. One key reason people need to invest in small marine diesel engines is their durability and efficiency, ensuring reliable performance on the water.

One of the primary advantages of small marine diesel engines is their fuel efficiency, making them a cost-effective choice for long journeys or frequent use. Additionally, these engines are known for their reliability and ability to withstand harsh marine environments, providing peace of mind to boat owners. Whether for recreational or commercial purposes, having the best small marine diesel engines ensures smooth sailing and efficient operation.

Boat owners looking for compact yet powerful engine options often turn to the best small marine diesel engines to maximize performance within limited space constraints. The compact size of these engines makes them suitable for a wide range of boat sizes, from small dinghies to mid-sized yachts, offering versatility and ease of installation for marine enthusiasts. Overall, investing in a small marine diesel engine is a smart choice for those seeking dependable and efficient power for their marine vessels, enhancing the overall boating experience.

Key Factors to Consider When Choosing Small Marine Diesel Engines

Choosing the best small marine diesel engine requires careful consideration of several critical factors. From power output and fuel efficiency to reliability and ease of maintenance, the decision-making process can be complex. By understanding and evaluating these key factors, you can select the ideal small marine diesel engine that suits your specific boating needs.

Engine Power And Performance

Consider engine power and performance when choosing small marine diesel engines to ensure your vessel can operate efficiently and effectively. The engine’s power output will impact your boat’s speed, acceleration, and overall performance on the water. Opting for an engine with the right power rating will provide sufficient propulsion for your specific boating needs, whether for leisure cruising or commercial purposes. Additionally, a well-performing engine can enhance fuel efficiency, reliability, and longevity, making it a crucial factor to consider when making a purchasing decision for small marine diesel engines.

Fuel Efficiency

Fuel efficiency is a crucial consideration when choosing small marine diesel engines due to its direct impact on operating costs and overall sustainability. Opting for a more fuel-efficient engine can significantly reduce fuel consumption, resulting in long-term savings. Additionally, improved fuel efficiency means lower emissions and reduced environmental impact, aligning with growing regulations and preferences for greener maritime operations. By selecting a small marine diesel engine that prioritizes fuel efficiency, users can enjoy cost savings, prolonged engine lifespan, and minimized ecological footprint, making it a wise and responsible choice for both economic and environmental reasons.

Size And Weight

Size and weight are crucial considerations when selecting small marine diesel engines due to the limited space available on boats. The engine must fit comfortably within the vessel without causing overcrowding or imbalances. Additionally, the weight of the engine can affect the boat’s overall performance and stability in the water. Choosing a compact and lightweight diesel engine ensures efficient use of space and optimal boat operation. By carefully considering the size and weight of the engine, boaters can enhance maneuverability, fuel efficiency, and overall safety while enjoying their time on the water.

Durability And Reliability

Durability and reliability are crucial when selecting small marine diesel engines because they directly impact the engine’s performance and longevity on the water. A durable engine can withstand the harsh marine environment, including saltwater exposure and constant vibrations, ensuring fewer breakdowns and maintenance issues. Reliability is essential for smooth sailing and peace of mind, as it assures boaters that the engine will start up consistently and operate efficiently when needed. By prioritizing durability and reliability in their purchase decision, boaters can enjoy greater confidence in their vessel’s engine performance and overall sailing experience.

Maintenance Requirements

Considering maintenance requirements is crucial when selecting a small marine diesel engine due to its impact on performance and longevity. Engines that require frequent and complex maintenance may lead to costly downtime and potential breakdowns. By opting for an engine with manageable maintenance needs, boat owners can ensure efficient operation and minimize the risk of unexpected issues. Additionally, engines that are easy to maintain can save both time and money in the long run, making them a practical choice for boaters seeking reliable and hassle-free performance from their marine equipment.

Maintenance Tips For Small Marine Diesel Engines

Regular maintenance is essential for small marine diesel engines to ensure optimal performance, longevity, and safety on the water. Here are some crucial maintenance tips to keep your engine running smoothly.

Firstly, adhere to the manufacturer’s recommended service schedule for oil changes, fuel filter replacements, and overall inspections. Regularly checking and maintaining proper oil levels and quality will help prevent premature wear and tear on engine components.

Secondly, pay close attention to the cooling system. Inspect and clean the heat exchanger, raw water strainer, and impeller regularly to prevent overheating and ensure proper cooling of the engine. Clogged or damaged components can lead to costly repairs or even catastrophic engine failure.

Additionally, keep fuel system maintenance a priority. Use clean, high-quality fuel and regularly drain any water or contaminants from the fuel filters. It is also important to inspect and clean the fuel injectors to maintain proper fuel delivery and engine performance.

Lastly, do not overlook the importance of inspecting belts, hoses, and electrical connections. Loose or worn belts and hoses can lead to serious engine malfunctions, while corroded electrical connections can cause starting problems or electrical system failures. Regularly check and replace these components as needed to keep your small marine diesel engine in top condition.

Fuel Efficiency Considerations

When considering small marine diesel engines, fuel efficiency is a crucial factor to take into account. Opting for an engine that offers good fuel efficiency can lead to significant cost savings over time, especially for vessel owners who frequently operate their boats for extended periods. Engines that consume fuel efficiently can help minimize operating costs and reduce the environmental impact of marine diesel engines.

Key factors that influence fuel efficiency include the engine’s design, technology, and fuel consumption rate at various speeds. Look for engines with advanced fuel injection systems and efficient combustion processes to maximize fuel efficiency. Additionally, engines with electronic controls can help optimize fuel usage by adjusting performance based on current operating conditions.

It’s also essential to consider the engine’s power output in relation to its fuel consumption. Choosing a properly sized engine that matches the vessel’s requirements can ensure optimal fuel efficiency. Regular maintenance, such as cleaning filters and tuning the engine, is vital for preserving fuel efficiency over the engine’s lifespan. By prioritizing fuel efficiency considerations when selecting a small marine diesel engine, boat owners can enjoy enhanced performance and cost-effectiveness on the water.

Troubleshooting Common Issues

In the Troubleshooting Common Issues section, you will learn how to effectively address and resolve common problems that may arise with small marine diesel engines. Understanding these issues and their solutions can save you time, money, and frustration while ensuring the smooth operation of your engine.

Common problems such as overheating, starting issues, unusual noises, and fuel system malfunctions will be discussed in detail. You will find practical tips on how to identify the root causes of these issues and the appropriate steps to take to rectify them promptly.

By following the troubleshooting techniques outlined in this section, you will be equipped with the knowledge and skills to diagnose engine problems accurately and implement solutions effectively. This will help you maintain the performance and longevity of your small marine diesel engine, allowing you to enjoy worry-free boating experiences.

Overall, the Troubleshooting Common Issues section serves as a valuable resource for boat owners and enthusiasts alike, offering practical guidance on how to troubleshoot and resolve common engine issues efficiently and effectively.

Frequently Asked Questions

What are the key factors to consider when choosing a small marine diesel engine.

When choosing a small marine diesel engine, key factors to consider include the engine’s power output, fuel efficiency, and reliability. It’s important to match the engine’s horsepower to the size and weight of the boat for optimal performance. Fuel efficiency is crucial for long journeys and cost savings. Additionally, opting for a reputable brand known for reliable engines can ensure smooth sailing and reduce the risk of breakdowns at sea. Regular maintenance and availability of parts should also be taken into account when making a decision.

How Does The Power Output Of Small Marine Diesel Engines Impact Performance?

The power output of small marine diesel engines directly impacts the performance of the boat or vessel. A higher power output allows for increased speed and acceleration, making it easier to navigate through rough waters or currents. On the other hand, a lower power output may result in slower speeds and reduced maneuverability, especially in challenging marine conditions. It is essential to match the power output of the engine to the size and weight of the vessel to ensure optimal performance and efficiency on the water.

What Maintenance Tasks Are Essential For Keeping A Small Marine Diesel Engine Running Smoothly?

Regularly check and change the engine oil, fuel filter, and air filter to ensure proper lubrication and clean fuel and air intake. Keep the cooling system in good condition by checking and topping up coolant levels and inspecting hoses for leaks or damage. Run the engine regularly to prevent build-up of carbon deposits and ensure all components are functioning properly. Conduct routine inspections for signs of corrosion or wear on components like belts, hoses, and gaskets to prevent breakdowns.

Additionally, adhere to the manufacturer’s recommended service schedule for tasks such as adjusting valve clearances, replacing injectors, and inspecting the turbocharger to maintain optimal engine performance. Regularly inspect the fuel system for leaks or contamination and use quality fuel additives to prevent microbial growth in the fuel tank. Store the engine in a clean and dry environment when not in use to prevent moisture-related issues and consider professional servicing by a marine diesel mechanic for more complex maintenance tasks.

How Does Fuel Efficiency Vary Among Different Small Marine Diesel Engines?

Fuel efficiency can vary among small marine diesel engines based on factors such as engine size, design, and technology. Generally, newer engines equipped with advanced fuel injection systems and turbocharging tend to be more fuel-efficient than older models. Additionally, the specific usage patterns and operating conditions of the engine can also impact fuel efficiency. Factors like vessel weight, cruising speed, and maintenance practices all play a role in determining the overall fuel efficiency of a small marine diesel engine.

In conclusion, small marine diesel engines with higher horsepower ratings and modern fuel-saving technologies are likely to be more fuel-efficient compared to older, lower-powered models. Regular maintenance and optimal operating conditions also contribute to maximizing fuel efficiency in small marine diesel engines.

What Are Some Recommended Brands Known For Producing High-Quality Small Marine Diesel Engines?

Some recommended brands known for producing high-quality small marine diesel engines include Yanmar, Volvo Penta, and Cummins. These brands are widely recognized for their reliability, efficiency, and performance in marine applications. They offer a range of compact and powerful diesel engines that are suitable for various types of boats and vessels, making them popular choices among boat owners and marine enthusiasts looking for durable and high-performing propulsion systems.

Final Words

To make an informed decision on the best small marine diesel engines, it is essential to consider factors such as power output, durability, and fuel efficiency. By comparing features and reading user reviews, buyers can find the perfect engine to suit their needs. Investing in a high-quality small marine diesel engine can ensure smooth sailing and reliable performance on the water. Choose one of the top-rated options available in the market for the best small marine diesel engines that will meet your boating requirements and offer long-term value.

Leave a Comment Cancel reply

Save my name, email, and website in this browser for the next time I comment.

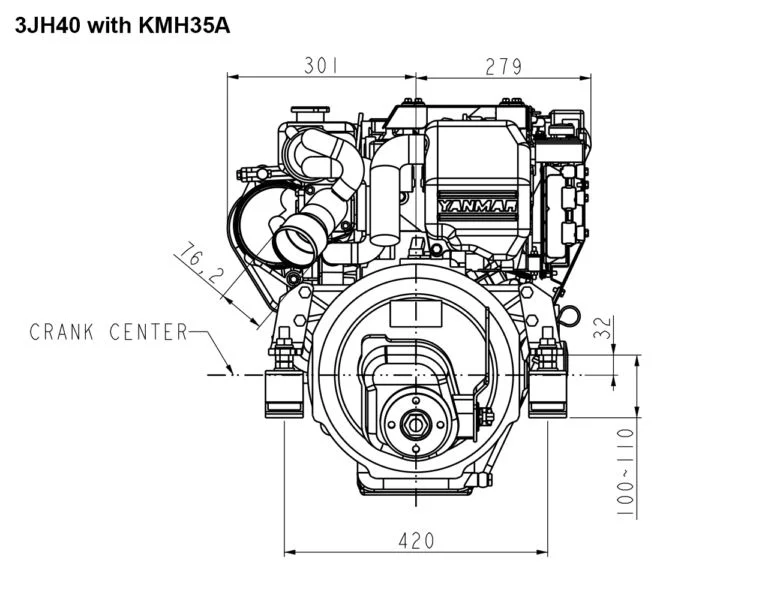

Specifications

NOTE: 1 kW = 1.3596 mhp = 1.34102 bhp Fuel condition: density at 15°C = 0.842 g/cm³ Technical data is according to (ISO 8665) / (ISO 3046) Fuel temperature 40°C at the inlet of the fuel injection pump (ISO 8665) Length includes KM35A marine gear (Dimensions may vary with other gears/elbow)

More Information

Winner of the miami 2018 innovation award for the inboard engine category.

The 3-cylinder 3JH40, with an output of 40 mhp, will enable a whole new category of smaller leisure boat owners and commercial vessel operators to benefit for the first time from the efficiency and performance advantages associated with the most recent electronically-managed CR fuel-injection technology.

With an output of 40 MHP @ 3000 rpm (29.4 kW @ 3000 rpm), the 3JH40 is the smallest common rail inboard marine diesel in:

- Displacement, with only 3 cylinders measuring 1.642 L (100 cu in)

- Physical size, measuring 774 x 580 x 632mm

- Weight, measuring 192kg without gear

Through common rail technology, the 3JH40 offers minimal fuel consumption and exceptionally low noise and emission levels, exceeding EPA Tier 3 and EU RCD Tier 2 emission regulations for virtually smoke and odor-free operation.

The 4-stroke, water-cooled 3JH40 is an ideal solution for new builds and repowering applications, specifically monohull sailing yachts and catamarans up to 45ft, small motor boats or sloops, and light duty commercial craft.

*The next largest common rail inboard marine diesel engines are the YANMAR 4JHCR line: 45, 57, 80, 110 MHP.

Drawings Download Drawings

Performance Curves Download Specification Datasheet

Standard Engine Package

- Exhaust mixing elbow [L-type]

- Alternator 12V – 125A

- Flexible mounts

- Mechanical throttle sensor

- Fuel pre-filter with water separator

- Fresh water expansion tank

- Belt safety cover

Optional Accessories

- High-riser mixing elbow [instead of L-elbow]

- Secondary alternator 12V – 125A or 24V – 60A

- Extension harness [3m, 5m, 10m]

- Second station

- TFX Sidemount control head

- VC10 Vessel Control System

- NMEA2000 Engine monitoring system

- Semi 2-pole

- SOLAS including Certificate [factory fit only]

- Hot water kit with cocks

- Extension saildrive leg [75 mm]

- Propeller cone nut kit SD60

- On-board spare parts kit

Operation Manual

Product guide, specification datasheet, technical drawings - bobtail, technical drawings - gear, technical drawings - saildrive, compatible products, gears / drives, controls / panels.

Kanzaki Gears

B25 & C35 Panels

Sign-up to receive the latest information about new products, services, and general updates.

YANMAR’S extensive global service and parts network spans 130 countries and over 2100 locations.

We’re here to help and would love to hear from you. Contact us with inquiries, comments, and feedback.

Elige tu idioma

Choisissez votre langue, velg ditt språk.

Nederlandsk

Portugisisk

Välj ditt språk

Portugisiska

16 HP - 11,8 kW 3600 RPM

27 HP - 20 kW 3600 RPM

31 HP - 23,1 kW 3000 RPM

42 HP - 30,9 kW 3000 RPM

50 HP - 36,8 kW 3000 RPM

59 HP - 43,4 kW 3000 RPM

60 HP - 44 kW 2700 RPM

64 HP - 47 kW 2500 RPM

82 HP - 60,3 kW 2500 RPM

94 HP - 69 kW 2500 RPM

103 HP - 75,8 kW 2500 RPM

160 HP - 118 kW 2300 RPM

196 HP - 143,9 kW 2300 RPM

272 HP - 200 kW 2300 RPM

Add new address, área privada solé diesel.

Introduzca su email y contraseña para acceder a su área privada.

Every sailor knows that operating and maintaining a diesel engine in a saltwater environment can be a challenge. Add to that the fact that many of these engines are upwards of twenty years old and may have a sketchy maintenance record. Enjoying sailing can often translate to being a part-time diesel mechanic .

Well, that’s where SaltWaterDiesels.com kicks in to gear. Here you can learn how to maintain, troubleshoot and repair your sailboat’s small marine diesel engine. There’s a little bit of history about the development of the diesel engine and some general advice about maintaining your engine.

We passionately believe that if you know how it works, then you will know how best to fix it.

This means that if your engine gives you trouble when you’re at sea, you have at least a fighting chance of getting it working again yourself. Self-sufficiency at sea (in this case the ability to solve minor engine problems) is the hallmark of a good skipper.

Let’s begin. Choose your engine by manufacturer…

- About Modern Wooden Boats

- Tips & tricks

- What’s inside a boat plan ?

Engine for small sailboats

Engine for small sailboats : how to choose it.

My projects are focussed on small sailboats, up to about 30 feet, boats on which the choice of the engine often has a heavy impact on the project from several points of view: costs, reliability, weights, effectivness of the propulsion system, safety at sea.

There are currently three main options to power a small (or not so mall, hirundo 750, Petrel 28) sailboat:

inboard diesel engine , both with shaft line transmission or saildrive one

outboard engine on transom bracket

electrical engine, both transom mounted as an outboard engine or fitted in bilge as a traditional diesel inboard one

until two decades ago this triple choice was simply not existent: small 2 strokes outboards were definitely unreliable (on J24 we used to go in and out of the harbour with sails mostly because we were SURE that our engine would have quitted working in the worst possible moment, providing us a plenty of adrenalinic moments…), electrical marine engines simply didn’t exist , so the only possible choice for a small cruising sailboat was a small inboard engine.

Nowadays things are definitely changed: small 4 strokes outboard engine are really sturdy and reliable , electric engine are becoming a reality year after year, and on the other side small diesel engines are stucked on models , technology , costs and weights not so different from 20 years ago, but nonetheless they are really workhorses;

Let’s now consider some of the choice parameters.

idea 19: a 5 HP outboard engine fitted on transom in central position, a good choice for smallest sailboats

engine has a dramatic impact on total budget on a small homebuilt boat that can be built with a budget of 20-23k euros (hirundo 750, very much less for idea 21 or 19) , let’s see how much dramatic:

10 hp 4 strokes outboard engine: it costs around 2700 € vat included , and can be purchased basically in each marina, additional costs to fit it on board are low: a plastic gasoline tank with pipes and plugs, a sturdy transom bracket, few bolts and nuts , and you have your powerplant ready to work ; if you want to go for a smaller 5 HP (perfect for Saltaspiaggia or idea 21), engine cost is about 1600 € ; there’s a wide market of second hand engines (pay attention, there are a lot of “archeological” outboard engines on the market…)

inboard diesel engine : thing become serious for our wallet: a fresh new 10 HP diesel engine fitted with saildrive costs around 7500-8500 €, a shaft line version, just engine and transmission, is about 5600-6500 € , in this case you have to buy also complete shaftline, bracket, propeller, and fitting all the system on board properly requires a good amount of experience (or hiring a mechanic, other costs) , and you even have to buy and fit ancillary systems: fuel tank and filters, exhaust system, and a dedicated engine battery and related wirings ; upgrading from 10 to 20 HP (good choice for bigger boats like Petrel 28) engine cost raises of about 2000 €, both for saildrive models and for shaftline one;

electrical engines: small electric outboards , perfect to power idea 21, costs around 2000€, and other 600-800 € are required for a spare battery pack, which IMHO a mandatory upgrade; for bigger boats, an electric engine that can be compared to a 10 hp endothermic one , in the 4kW class, can be purchased for around 3700 euros, with no batteries; if you add an AGM battery pack for at least 2 hours of endurance total cost raise to 5700-6700 euros , definitely more expensive than an outboard gasoline engine and not so far from the workhorse diesel inboard engine

use related costs: that is to say , mainly, fuel: given the fact that we’re talking about small engines, fuel rates goes in the order of few liters/hour (tipically 2-3 for 10 Hp diesel inboard and 1.5 for 5Hp outboard engine), so there are not big differences between diesel inboard and gasoline outboard ; of course as long as you have an electric plug in your marina, recharging an electric engine battery pack is free

- servicing: small outboard engines can be taken away form the boat quite easily, so you can service them by yourself in your house’s garden or take them to a mechanic, same thing for electric engine, both outboard and inboard, since they’re quite light ; on the other side, removing a diesel inboard engine is a quite complicated task, and you’ll be forced to service it on board, they’re normally removed only for major overhauling or to be replaced

Reliability

sailboats are made to set on sails and turn off the engine, any sailor know the magic of this moment , but there are several situations in which you have to turn on the engine, even for a good amount of time, and sometimes you have even to push hard your engine: strong tidal streams, strong upwind seas, total zero wind situations (and sometimes even no wind and big waves which is quite annoying), emergency situations due to failures on board and so on; so we need a reliable engine in which we can trust ; I’m not considering here the normal situation in which you’ll turn on the engine for 10-20 minutes to sail away from your marina in calm-normal seas, for this standard purpose each engine is fine; in case of smallest boats, up to 23 feet, I’d anyway go for a electric engine (first choice) or a outboard 4 stroke engine, taking care that our battery pack for the electric engine gives us enough endurance, which may be a decent headache ; for bigger boats, from 23 to 30 footer, diesel inboard engine can be a good choice, and becomes the best choice if you normally need to motor for a quite long amount of time; in this last situation electric engine might be also a good choice but it’d be hugely compromised by the weight of a properly sized battery pack , or by its cost if you go for a light hi tech Litium-polymeric battery pack (they may cost a huge percentage of your entire boat) ; outboard engines often suffer from poor installation on a high placed transom bracket, that may lead the propeller to jump out of the water in short and steep waves with boat pitching, so the engine may be reliable in itself but its set up lead to a unreliable usage (a small well in the cockpit will make the outboard work veeeeery much better, see picture below)

in my humble opinion this is definitely the smartest way to fit an ouboard engine if you have a roomy cockpit : engine is on the centerline, propeller is in a very good position and it can work even with the boat heeled , and if you have to work on the engine you can do it in the cockpit, not hanging outboard in the weirdest positions

inboard diesel engine: Lombardini 20 HP fitted with saildrive on Petrel 28, an uncompromised classical choice for a mediterranean cruiser

a very neat and clean inboard electric engine fitted on a wooden boat : will this be the future ?

we’ll keep on with this subject in the next part of this post, stay tuned !

- Metric (cm, liter)

- Imperial (inch, gallon)

Marine Diesel Engines

At VETUS, we understand the profound connection between boat owners and their vessels. Consequently, we take immense pride in having developed a complete range of certified marine diesel engines to suit the most diverse and stringent of expectations.

With almost 60 years of experience in engineering onboard systems, we embrace the importance of delivering products that embody innovation, reliability, and exceptional quality.

Our commitment to excellence is reflected not only in the products we develop but also in the support and services available to you.

VETUS: Marine Diesel Engine overview

Our marine diesel engines' design transform your boating experience into one of joy and comfort. Whether you're seeking the power to cruise swiftly or the tranquility of a quieter voyage, VETUS has a solution.

M-Line Engines - Excellence in Small Marine Diesel Engines

The M-Line marine diesel engines excel in power, torque, reliability, and fuel efficiency. Developed with pioneering and exclusive technologies, including a water-cooled aluminum top cover and a new air inlet filter housing to reduce heat and noise levels. They are ideal for launches, yachts, canal boats, and cabin cruisers up to 52 HP.

The M-line engines are available in twelve different models, with or without sail drive and power output ranging from 12 hp to 52 hp.

H-Line Engines - A perfect balance of reliability and performance

Keeping durability and reliability at the forefront, our H-Line engines are meticulously crafted. Consequently, they emerge as the preferred choice for diverse applications, ranging from cabin boats and small fishing vessels to sizable canal boats. Due to their sturdy construction, the H-Line engines exhibit remarkably low noise and vibration levels, ensuring a comfortable and enjoyable boating experience.

H-line engines, with superior power-to-weight and fuel efficiency, come in 63 HP and 80 HP versions.

D-Line Engines: Common-rail technology for heavy displacement boats

The D-Line engines power heavy displacement boats, offering an exceptionally smooth performance at low rpm. Featuring a unique water-cooled top cover and a range of innovative features and optional such as a second high-output alternator, our D-Line engines are ideal for long-distance cruising.

The D-line is available in four different versions, with:

Peace of mind and performance - The best output of an engine

VETUS marine diesel engines are more than just products; they represent a commitment to quality, innovation, and customer satisfaction. Whether you're seeking efficiency, durability, or high performance, our engines will do the job.

With nearly 60 years' experience and a vast dealer network, we aim for every boater to navigate confidently and joyfully. Embark on a journey that is powered by innovation, reliability, and technical expertise.

Subscribe to our newsletter

Receive the latest information about offers, promotions and news

21 Best Diesel Marine Engines for Your Fishing Boat

- By Cameron J. Rhodes

- Updated: May 31, 2022

It’s difficult to even quantify the importance of a reliable marine diesel engine . Sport-fishing boats around the world simply wouldn’t have the legs to do what they do without these expertly and carefully crafted diesel machines. Evolving technologies continue to produce highly efficient and advanced engines for marine applications, whether starting new or repowering. Here, we’ve compiled a list of some of the best in the business.

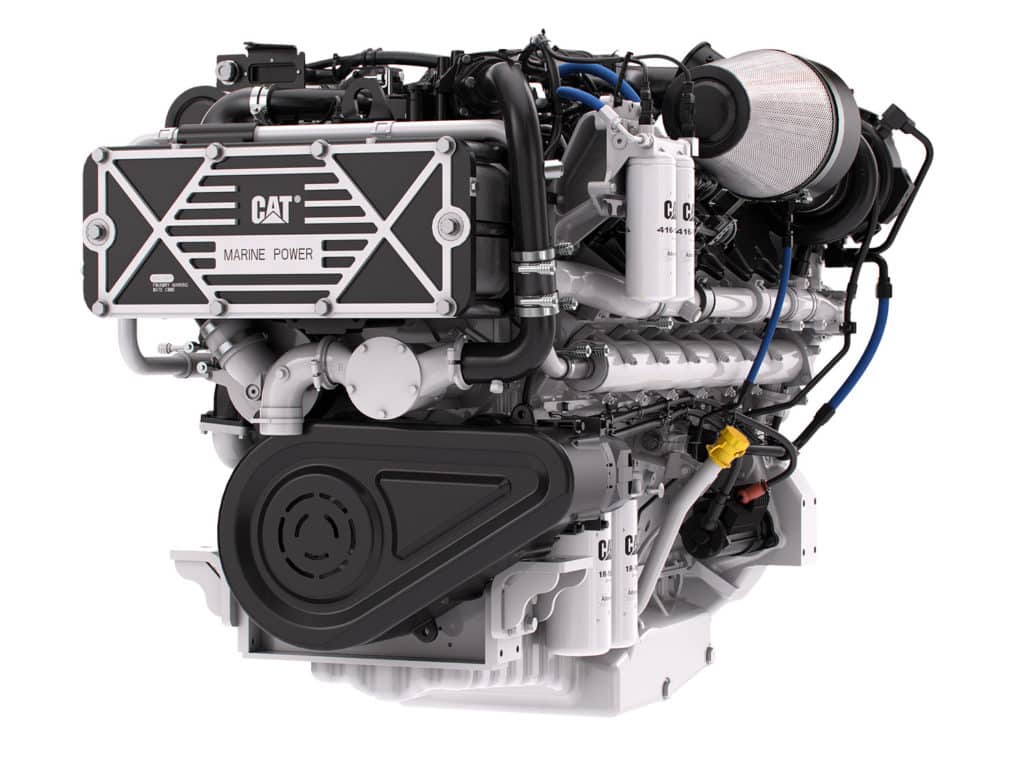

Caterpillar C18 Marine Diesel Engine

The Cat C18 is a popular in-line, six cylinder, and 4-stroke marine diesel engine for various sport-fishing applications. With a range of 1,015 mhp to 1,150 mhp, this engine offers maximum benefits in power density emissions, performance, and fuel efficiency. Expect an advanced aftercooler system and turbocharger, along with compatibility with Cat display and vessel control systems. The Cat C18 is EPA Tier III compliant and runs at 2,300 rpm.

Specifications

- Horsepower: 1015-1150 MHP

- Dry Weight(lbs): 4000-4299

- Displacement: 1106 cubic inches

Caterpillar C32B 2025 Marine Diesel Engine

The Cat C32 engine lineup has a longstanding history of excellence among sport fishing enthusiasts. The C32B 2025 engine boasts a laundry list of updates from previous models, resulting in greater speed and power. EPA Tier III compliant, the C32B 2025 engine weighs in at 6,780 pounds dry, just slightly heavier than older models in the lineup, all while ensuring 5 percent more power. Compared to previous engines in the C32 series, this model offers a 25 percent noise reduction with an advanced unit injection system when operating at low speeds. The size and shape of the engine has changed so little that a drop-in replacement is possible when repowering and replacing an older C32 model.

- Horsepower: 2,025 MHP

- Dry Weight(lbs): 6,780

- Displacement: 1,959 cubic inches

Caterpillar C32B 2433 Marine Diesel Engine

Much like other engines in the Cat C32 lineup, the C32B 2433 is a cutting-edge machine that promises speed and power. This model has all the upgrades seen in the C32B 2025 engine, along with some special features. Expect even better performance with an updated cooling system and a sequential air system. In addition, this model offers 20 percent more power output within the same reliable package.

- Horsepower: 2,433 MHP

Cox CXO300 Marine Diesel Outboard Engine

Designed with various uses in mind, the CXO300 stands alone in this list as the only diesel outboard engine. The CXO300 produces 30 percent less CO2 emissions thanks to its 30 percent fuel savings. These metrics certainly bode well for the eco-friendly. Operating at 479 foot-pounds of torque, boaters can expect to reduce emissions without giving up speed. Running at 300 hp and 3,700 to 4,000 rpm, this world-class diesel outboard engine has a dry weight of 866 pounds.

- Horsepower: 300 HP

- RPM: 3,700-4,000

- Dry Weight(lbs): 866

- Displacement: 266 cubic inches

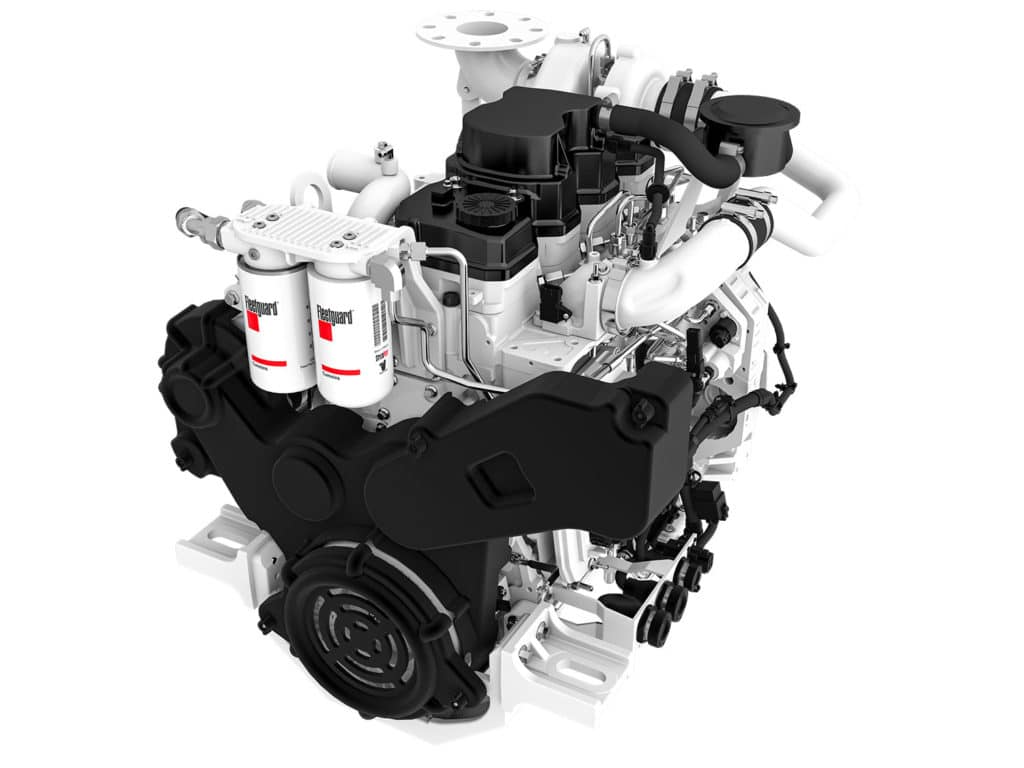

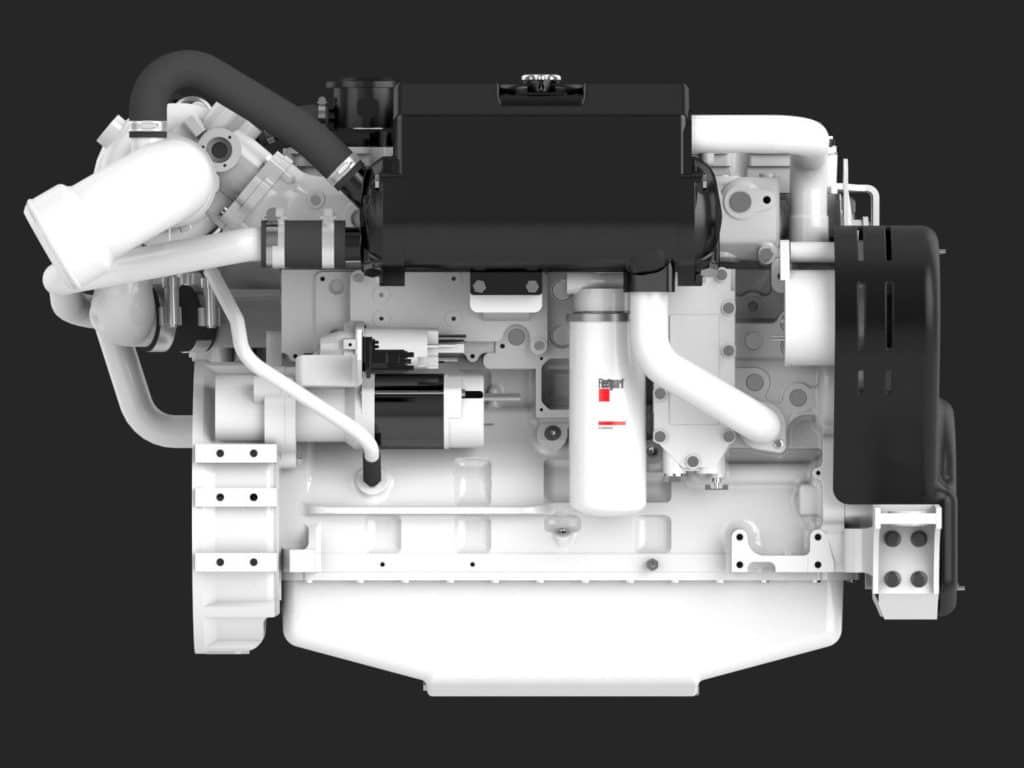

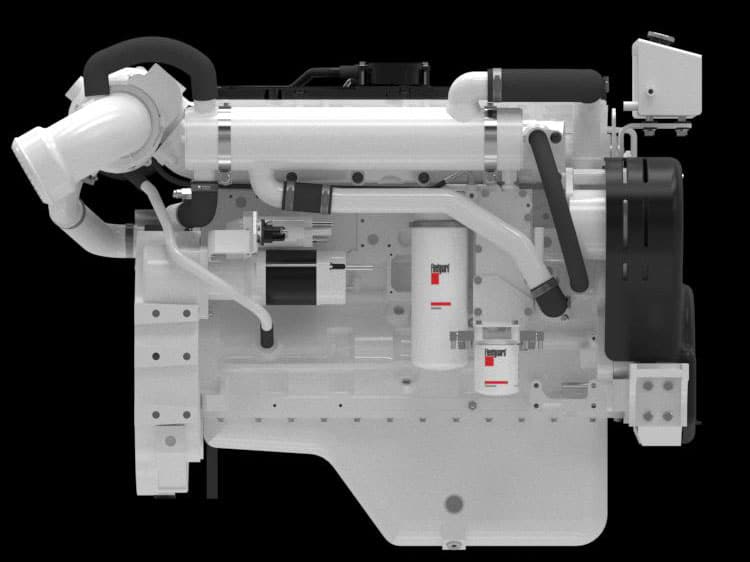

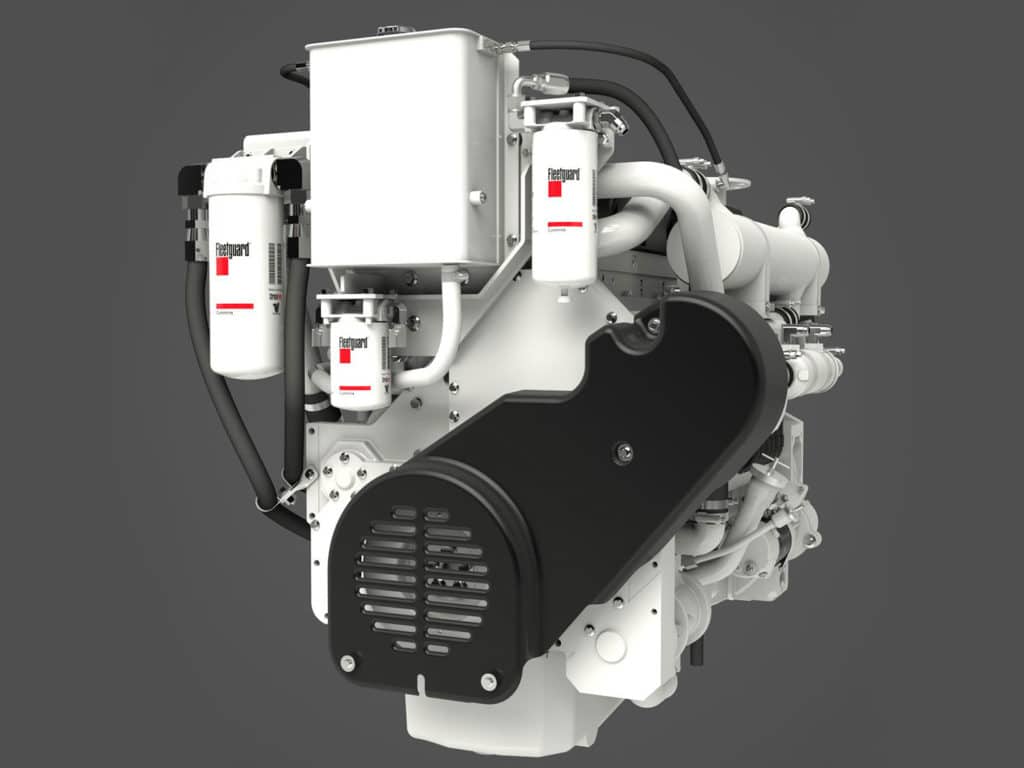

Cummins B4.5L Marine Diesel Engine

The Cummins diesel B4.5L engine for marine applications was developed based on the B4.5L industrial version. Compliant with EPA Tier III standards, the B4.5 is an inline, 4-cylinder, 16-valve, and 4-stroke marine diesel engine. Running at 230 bhp and 2,600 rpm, this turbocharged model has a dry weight of 1,202 pounds and a displacement of 272 cubic inches.

- Horsepower: 230-250 BHP

- Dry Weight(lbs): 1202

- Displacement: 272 cubic inches

Cummins QSB6.7 Marine Diesel Engine

The Cummins QSB6.7, an in-line, 6-cylinder, and 4 stroke marine diesel engine, offers an 80 percent reduction in noise when idling thanks to its common-rail fuel system. EPA Tier III compliant, this engine helps to improve the boating experience by eliminating smoke. The QSB6.7 weighs in at 1,450 pounds and boasts up to 3,300 rpm.

- Horsepower: 247-542 BHP

- RPM: 2,600-3,300

- Dry Weight(lbs): 1,450

- Displacement: 408 cubic inches

Cummins QSC8.3 Marine Diesel Engine

An in-line, 6-cylinder, 4-stroke diesel marine engine, the Cummins QSC8.3 offers impressive power density. The common rail fuel system improves fuel economy and reduces smoke. The engine meets EPA Tier III standards. With an impressive rpm range of 2,600 to 3,000, the QSC8.3 delivers 493 to 592 bhp.

- Horsepower: 493-592 BHP

- RPM: 2,600-3,000

- Dry Weight(lbs): 1,975

- Displacement: 505 cubic inches

Cummins QSL9 Marine Diesel Engine

The QSL9 is another in-line six-cylinder, four-stroke marine diesel engine from Cummins. This model is known for its longevity, having been used in commercial trawling fleets. Like other models in the Cummins marine diesel engine lineup, the QSL9 virtually eliminates smoke when starting up and reduces noise. Expect great fuel economy when traveling long distances at cruising speeds. EPA Tier III compliant, the QSL9 offers 405 bhp and 2,100 rpm.

- Horsepower: 405 BHP

- Dry Weight(lbs): 2,153

- Displacement: 542 cubic inches

Cummins QSM11 Marine Diesel Engine

The Cummins QSM11 offers proven acceleration and torque performance with a horsepower range of 295 to 705 bhp. Its innovative four-cycle design enables fuel efficiency and reduces noise. As expected in Cummins’ industry-leading engines, the QSM11 puts off little to no smoke and meets EPA Tier III standards. The QSM11 weighs in at 2,620 pounds with a displacement of 661 cubic inches.

- Horsepower: 295-705 BHP

- RPM: 1,800-2,500

- Dry Weight(lbs): 2,620

- Displacement: 661 cubic inches

Cummins 6BT/6BTA ReCon Marine Diesel Engines

ReCon engines offer buyers a great way to both save money and benefit the environment. When choosing to purchase a ReCon engine, Cummins doesn’t simply repair or rebuild it for you. Instead, Cummins ensures it meets remanufacturing standards by having it reconstructed and replacing old parts with new (as necessary) at specially authorized factories. The 6BT and 6BTA ReCon marine diesel engines from Cummins are built to at least meet or exceed the performance specifications of the original engine. These models can be used to replace and repower older Cummins engines or those from other manufacturers. The 6BT and 6BTA are both in-line, 6 cylinder, 4-stroke diesel marine engines. The 6BT model meets EPA Tier III standards at certain speed ratings.

- Horsepower: 220-370 MHP

- Dry Weight(lbs): 1,025

- Displacement: 359 cubic inches

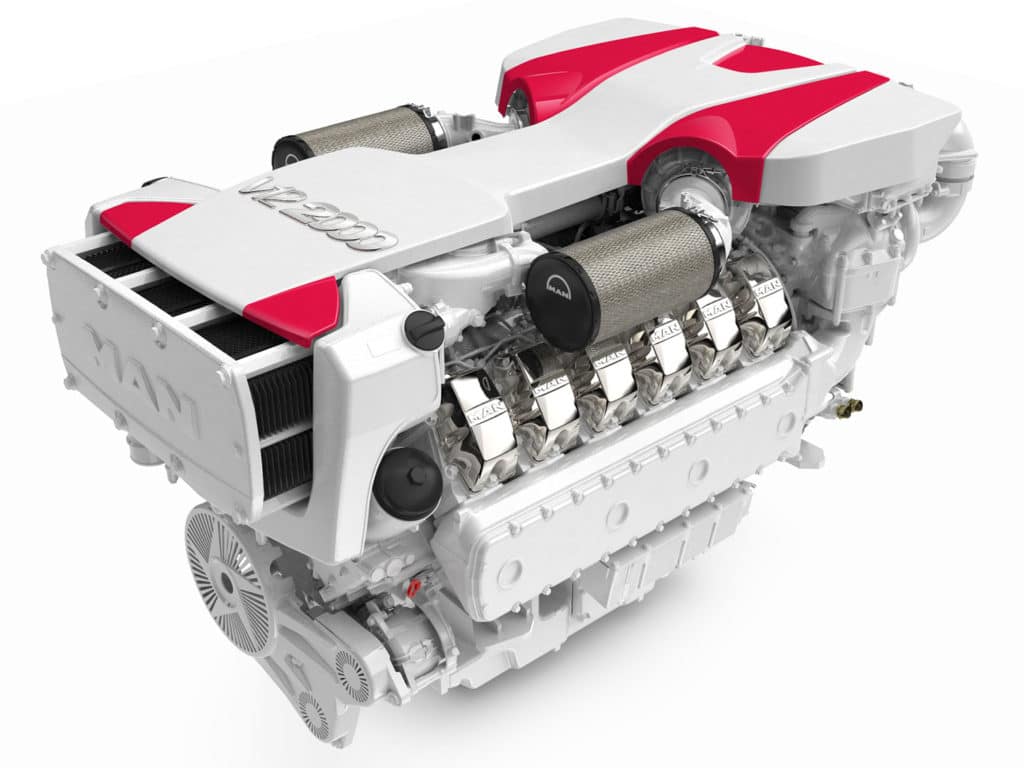

MAN V-2000 hp Marine Diesel Engine with e-Motion Hybrid Parallel Propulsion System

The e-Motion diesel hybrid system is unlike any other listed here. The Hybrid Parallel Propulsion system allows boaters to run in various modes such as full diesel traditional propulsion mode, diesel-electric navigation mode, and zero-emissions mode. Under the dedicated sport fishing hybrid package, the system enables unparalleled fuel savings and sound reduction, allowing for four hours of run-time in zero-emissions trolling mode. Once those four hours are up, the operator can restart the diesel engine and fast recharge the lithium battery packs within just 20 minutes. Preassembled and ready for installation, the Hybrid Parallel Propulsion System can be combined with variable speed generators to increase acceleration.

- Horsepower: Full range from 850 to 2,000 HP + 325 HP

- Dry Weight(lbs): 5,950 (as shown)

- Displacement: 1,476 cubic inches (as shown)

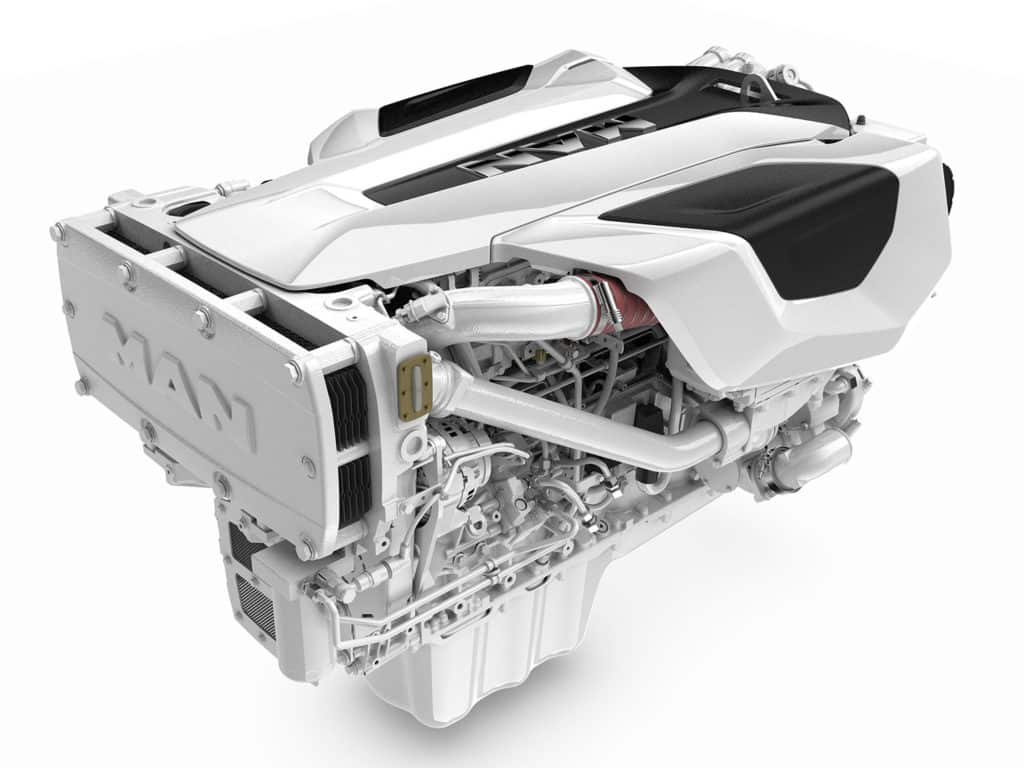

MAN i6 Marine Diesel Engine

Available in three variants (i6-730/800/850), the in-line six-cylinder i6 upholds MAN’s standards for high power density, as well as smooth and quiet operation. The i6 features an advanced plate heat exchanger, which also reduces maintenance requirements. The marine diesel engine’s common-rail fuel injection system, which can be controlled electronically, optimizes combustion, resulting in lower vibrations, less noise, and decreased fuel consumption. Weighing in at 1,251 kilograms, this engine meets the EPA Tier III requirements and offers an impressive horsepower-to-weight ratio.

- Horsepower: 730-850 HP

- Dry Weight(lb): 2,752

- Displacement: 12.42 liters

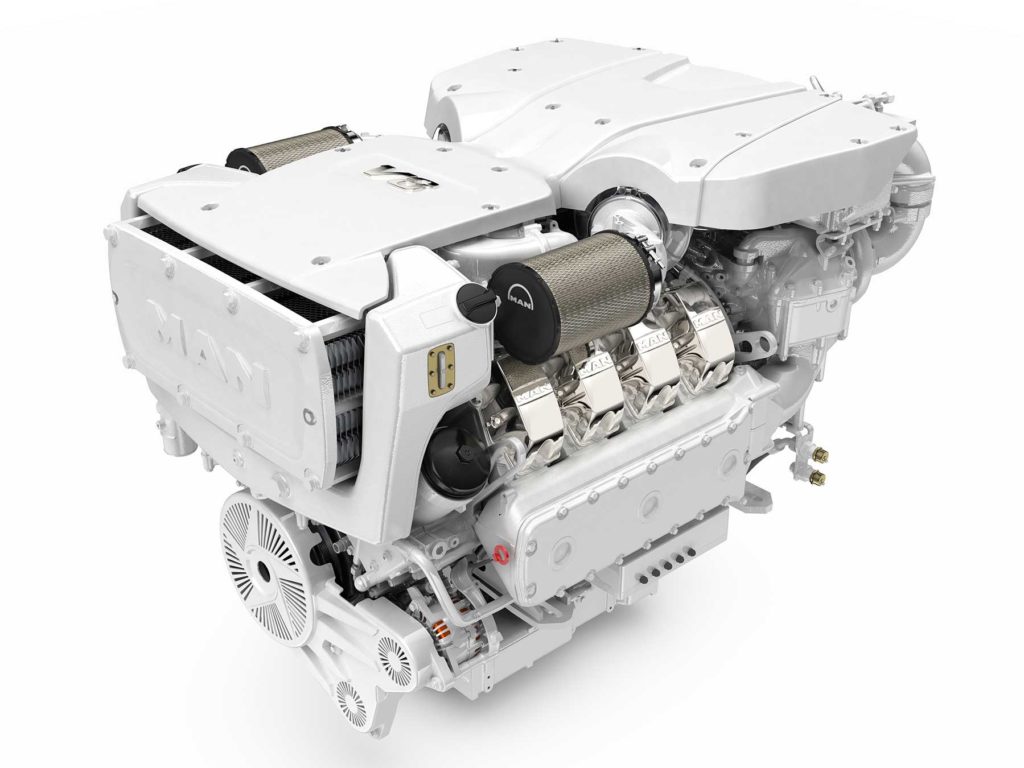

MAN V8 and V12-1900 and V12-2000 Marine Diesel Engine

Although the power rating of MAN’s V lineup has increased, folks can still expect these engines to be lightweight with a small overall footprint. Given the limited space available on sport-fishing boats , a thoughtfully designed and streamlined package is a must, and MAN delivers.

The V12-2000 is the earliest engine of its kind: a 12-cylinder V-engine with 2,000 hp. With a displacement of a mere 24 liters, this engine generates an enormous amount of power. The V8 and V12 engines offer many power ratings from 1,000 to 2,000 hp and are all EPA Tier III compliant.

- Horsepower: 1,000-1,200 HP

- Dry Weight(lb): 3,916-5,324

- Displacement: 16.16/24.24 liters

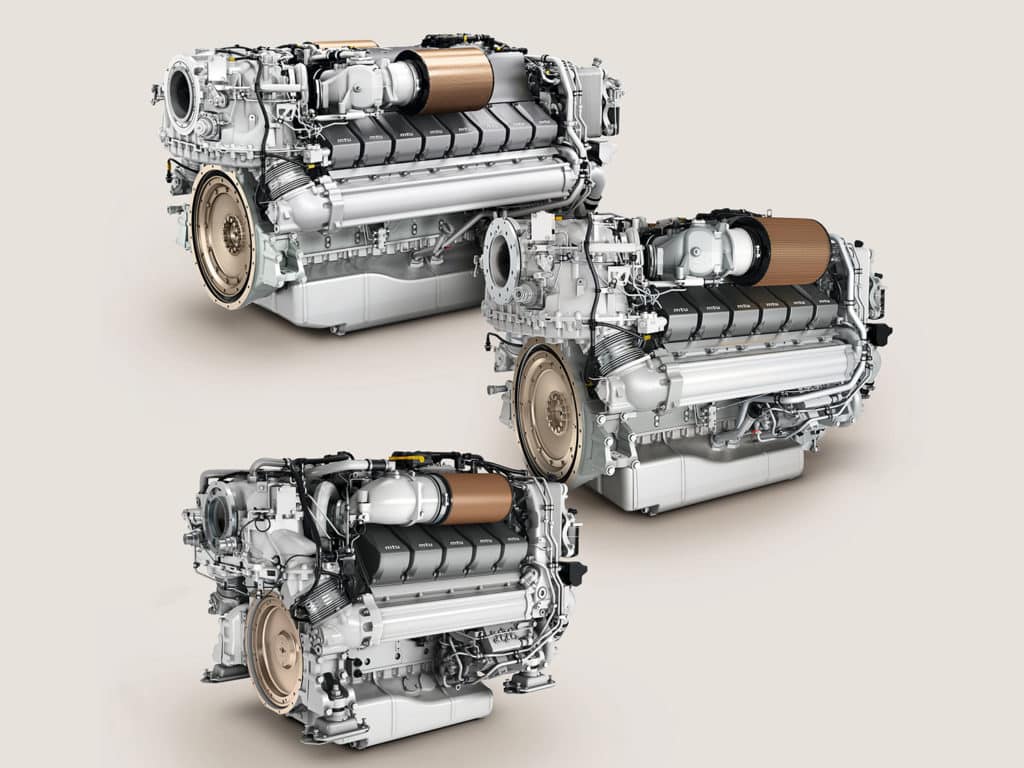

MTU Series 2000 Marine Diesel Engine

Performance is the first thing that comes to mind with the range of MTU 2000 series, which feature the 10V, 12V, and 16V versions. These diesel engines offer 1,360 to 2,600 hp and are designed specifically for high-speed marine use, and are ideal for both new builds and repowers. Each engine in this family boasts precise responsiveness, impressive acceleration, quiet operation and the great benefit of no smoke. MTU Series 2000 engines boast an unprecedented power-to-weight ratio. All of the models in the Series 2000 marine diesel range meet the EPA Tier III standards.

- Horsepower: 1,360-2,600 BHP

- Dry Weight(lbs): 5,082-7,606

- Displacement: 1,362-2,179 cubic inches

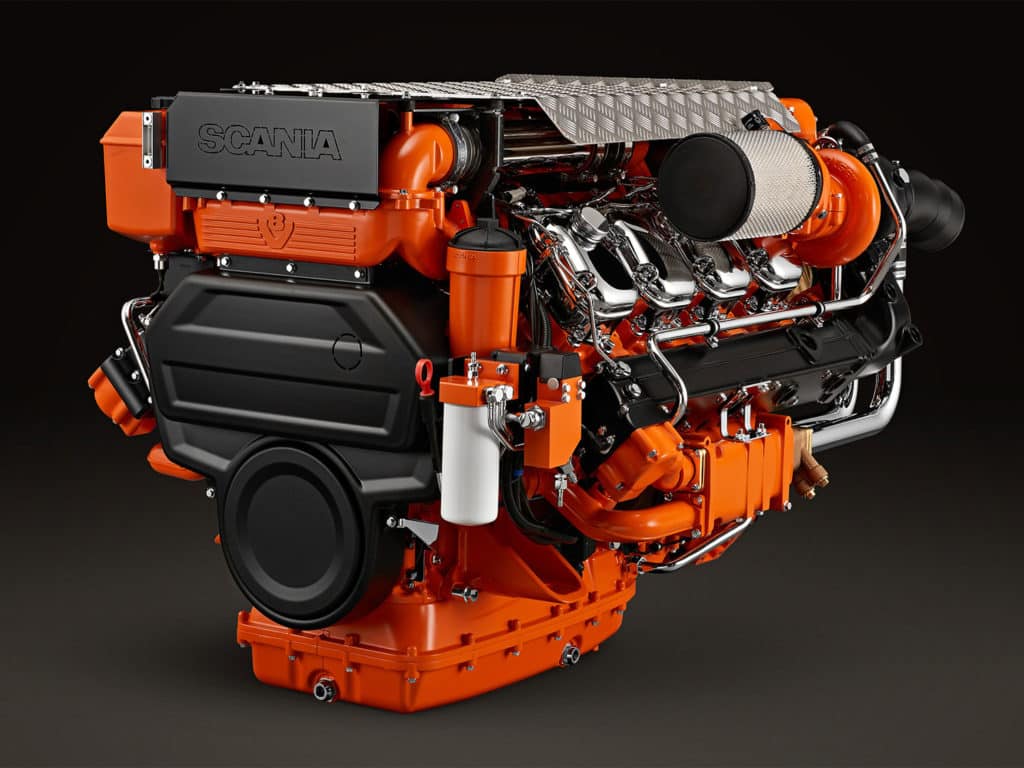

Scania DI13 Marine Diesel Engine

Designed to withstand some of the toughest conditions, Scania’s compact and lightweight engines are built to last. The DI13 is built on a compacted graphite iron engine block with a simple wastegate turbocharger, allowing for top performance. The engine offers optimal fuel delivery via its common-rail extra high-pressure injection system and Scania’s Engine Management System. Expect greater torque, less noise, and improved fuel efficiency. The DI13 is EPA Tier III compliant at certain ratings and weighs in at 2,832 pounds, offering an impressive power-to-weight ratio.

- Horsepower: 700-900 HP

- Dry Weight(lbs): 2832

- Displacement: 12.7 liters

Scania DI16 Marine Diesel Engine

The Scania DI16 model is a 16-liter V8 which delivers up to 1,150 hp. This engine offers all of the great features available in the DI13, but with greater power. Scania ensures that its engines, including the DI16, are easy to install and repair, with separate cylinder heads so that a technician can change a head on site. Buyers can expect greater torque, less noise, and improved fuel efficiency. The DI16 model has a dry weight of 3,659 pounds and a displacement of 16.4 liters.

- Horsepower:1,000-1,150

- Dry Weight(lbs): 3,659

- Displacement: 16.4 liters

Volvo Penta D4 DPI and D6 DPI Marine Diesel Engines

Ranging in horsepower of 150 to 440, the Volvo Penta D4 DPI and the Volvo D6 DPI feature a robust block with ladder-frame construction. The D4 and D6 are both equipped with common-rail fuel injection systems, superchargers, turbochargers, and charge-air coolers. Volvo Penta’s advanced electronic control system allows for low fuel consumption and emissions. Exceeding EPA Tier III standards, the D4 and D6 allow for a more enjoyable day on the water with reduced vibration and noise.

- Horsepower: 150-440 HP

- RPM: 3,400-3,700

- Dry Weight(lb): 1,444-1,742

- Displacement: 224-336 cubic inches/3.7-5.5 liters

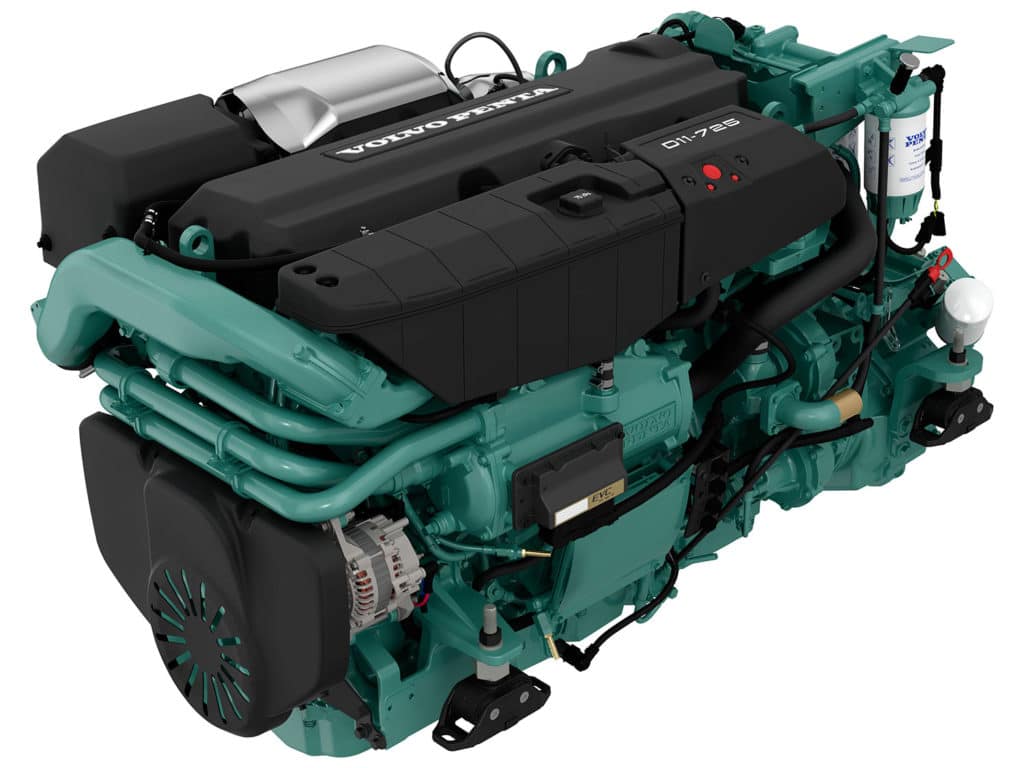

Volvo Penta D11-725 Marine Diesel Engine

Volvo Penta’s D11-725 is an in-line six-cylinder diesel marine engine that gets up to 725 hp. Like other marine diesel engines in Volvo Penta’s lineup, expect low emissions and excellent performance thanks to the D11’s camshaft, twin-entry turbo, and common-rail fuel injection system. EPA Tier III Compliant, this engine runs at 2,500 rpm with a dry weight of 2,524 pounds.

- Horsepower: 725 HP

- Dry Weight(lbs): 2,524

- Displacement: 661 cubic inches/10.8 liters

Volvo Penta D13-IPS1350 Marine Diesel Engine

Volvo Penta’s D13-IPS1350 is the big sister to the D13, offering longer range at a lower fuel consumption and reduced emissions. Buyers can expect powerful performance as well as maneuverability. One of the greatest features that sets the D13-IPS apart from other engines in the Volvo Penta marine diesel engine lineup is its twin counter-rotating propellers. Made from a cast-iron cylinder block, this model boasts greater longevity and durability. The D13-IPS1350 is EPA Tier III compliant and comes with a fully integrated system courtesy of Volvo Penta’s Electronic Vessel Control.

- Horsepower: 1000 HP

- Dry Weight (lbs): 5,419

- Displacement: 780 cubic inches

Volvo Penta D13-1000 Marine Diesel Engine

Another in-line six-cylinder engine from Volvo Penta, the D13-1000 features many of the same benefits offered in the D11, but with additional power. With 1,000 hp at 2,400 rpm, this marine diesel engine offers impressive performance with low emissions. In addition, the D13-1000 has a high-pressure unit injector system, another contributor to the world-class fuel efficiency expected of Volvo Penta products. The D13 also meets the standards for EPA Tier III compliance.

- Horsepower: 1,000 HP

- Dry Weight(lbs): 3,605

Yanmar 6LF550 Marine Diesel Engine

Complementing the largest common-rail marine diesel engine lineup available, the 6LF range from Yanmar offers compact, lightweight and high-performance solutions ideal for the sport-fishing sector. The global emission-certified inline 6-cylinder, 4-stroke, vertical water-cooled diesel engines offer leading fuel economy and feature Yanmar’s proprietary fuel mapping and a larger mixing elbow for reliable and consistent output performance. The three output models from 485 to 550 mhp are controlled by the next-generation Yanmar VC20 system, for three engines with up to four stations. The 3,000-rpm engines are custom engineered to offer direct connectivity to NMEA and J1939 CAN-bus networks. Suitable for boats up to 55 feet, the 6LF550 model creates a high-power density of 82 mhp/l.

- Horsepower: 550 mhp

- Dry Weight (lbs): 1,720

- Displacement: 411 cubic inches

- More: Boat Engines , Sport Fishing Boats

Free Email Newsletters

Sign up for free Marlin Group emails to receive expert big-game content along with key tournament updates and to get advanced notice of new expeditions as they’re introduced.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

By signing up you agree to receive communications from Marlin and select partners in accordance with our Privacy Policy . You may opt out of email messages/withdraw consent at any time.

Scania-Powered Viking 48: Showcasing Performance and Efficiency

Invincible 43 Open: A Game-Changer in High-Performance Fishing Boats

Ring Leader: The Life and Legacy of Randy Ringhaver

Preview of the Viking 82: A Luxurious Five-Stateroom Sportfisher

Bay Point Billfish Open Draws 80 Boats and Awards $1.5 Million in Prizes

Fender Bender Wins 2024 Bermuda Billfish Blast with Record-Breaking Payout

Cape Verde Produces 2024 Blue Marlin World Cup Champion

Doc Fees Dominates in Hatteras

- Digital Edition

- Customer Service

- Privacy Policy

- Terms of Use

- Email Newsletters

- Tournaments

- Expeditions

Many products featured on this site were editorially chosen. Marlin may receive financial compensation for products purchased through this site.

Copyright © 2024 Marlin. A Bonnier LLC Company . All rights reserved. Reproduction in whole or in part without permission is prohibited.

Sign up for free Marlin Group emails to receive expert big-game content along with key tournament updates and to get advanced notice of new expeditions as they’re introduced.

Subscribe to Marlin

Subscribe now to get seven keepsake print editions of Marlin per year, along with instant access to a digital archive of past issues, all for only $29 per year.

- Bermuda Triple Crown

- Los Cabos Billfish Tournament

- Offshore World Championship

- Scrub Island Billfish Series

- Marlin Expeditions

- Guatemala – Ladies Only

- Nova Scotia

- Dominican Republic

- Galápagos Islands

- Expert Instructors

- Corporate Retreats

- Our Sponsors

- Newsletters

You are using an outdated browser. Please upgrade your browser or activate Google Chrome Frame to improve your experience.

We Deliver To Your Door In Canada

24 hr Worldwide Shipping

Your cart will be saved on this device for 30 days.

From 8am - 5pm (USA - Est)

Parts Specialist

English - Español

Home | Blog | Finding the Most Reliable Marine Diesel Engines

Finding the most reliable marine diesel engines.

When it comes to a large-scale investment, such as a marine diesel engine, you need to carefully consider your options to ensure you choose the right one. You need to keep your requirements and budget in mind and understand the differences in horsepower, engine size and propulsion between various engines.

Choosing the right marine diesel engine can be challenging, but at Diesel Pro Power , we simplify the process. We stock top-tier, reliable marine diesel engine parts as well as other boat parts, and our site is designed to make finding the right parts easier than ever. We supply diesel engine parts from top brands like Cummins and Detroit Diesel . To make it the process even easier for you, we’ve created this guide on how to choose a diesel engine for marine applications.

Why Weighing Your Options Matters

Instead of leaping into a massive purchase, your best bet is to investigate and research your available options. Being aware of proper diesel engine information can ensure you make the optimal investment and the right choice for your specific boat or yacht.

Will the existing options meet your needs and expectations? To see what’s available on the market, you will need to manage some research. You can keep it simple by browsing various online vendors and manufacturers, magazines, newspapers, TV ads, etc. You can read forums and surveys that describe which makes and models are best for particular applications. Another simple step you can follow includes making a list.

Write down what you need and what you want out of your marine diesel engine. You can update and revise it as you learn more about your options. From there, break it down into the essentials — what you need the engine to have for basic operation and a wish list for characteristics you’d like to have. Are you looking for new or used diesel engines? How much horsepower does your vessel necessitate?

It can also be helpful to research recent trends and projects for the marine diesel engine market. Doing so can give you insight into what to expect as you compare diesel engines. For example, according to Global Market Insights, Inc., high-speed engines made up more than 20% of the marine diesel engine market in 2016, and the total market for marine diesel engines is predicted to grow at more than 5% and exceed $7 billion by 2024.

As you compare marine diesel engines, focus on features, price and quality. Start by eliminating engines with features that don’t match your expectations. Set up criteria and drop anything that doesn’t fit, then fine-tune the list to match your exact needs. Creating a spreadsheet can help you stay organized.

Next, define a price or price range that you’re comfortable spending and cross off everything that doesn’t conform to the budget. Be flexible, however, because having a range that you can work with is better than a set price. Then, listen to the experts. They know which engines are ideal for particular applications and have insights on industry trends and specific makes and models.

Finally, balance out the features, price and quality, remembering to prioritize quality over price. While you may be on a budget, investing in a high-quality engine will support you in the long-run. Pair your three researched elements with reviews and expert advice, then narrow down the engine to one or two options.

Determine What You’re Looking For

Before you buy a new marine diesel engine, evaluate the products you’re considering in more detail. Think about aspects such as the desired level of power, the different power options and the applications for which you’ll use the engine.

One crucial factor is how much power your vessel needs. The professionals at Diesel Pro Power can help you determine this. It can also be helpful to run a sea-trial with the available models. Sea-trials can help you get a feel for what you require. Understanding the power-to-weight ratio of a diesel engine is also crucial because a 25 to 50 HP variance can have a massive impact on performance.

Once you determine the horsepower you need, the weight of the engine is the next step. Other considerations include the physical dimensions of the engine as well as the motor mount footprint. If you’re looking to invest in an engine that doesn’t match the OEM, you will want to think about whether you will have access to parts like filters and water pump impellers.

Is your engine for applications like a cruise or cargo ship? Or for a yacht or fishing boat? Are you in need of a two or four-stroke trunk piston engine or a two or four-stroke cylinder engine? Asking yourself these questions will help you make the right decision.

Propulsion Systems to Take Into Consideration

There are numerous types of propulsion systems for marine diesel engines, including waterjet, pod and propeller.

Waterjet propulsion: A waterjet system has a ducted pump or propeller that forms a jet of water by forcing the liquid through a nozzle.

Pod propulsion: Mounted to a steerable pod that’s attached to the hull, a pod propulsion structure has a pitch propeller that’s linked to the engine through a mechanical link or diesel-electric link.

Propeller system: A propeller system is a fan system that converts rotational motion into thrust.

A waterjet propulsion system is ideal for ski-sport boats, picnic boats, personal watercraft and other vessels that operate in shallow waters. With this system, the engine draws in water through the bottom of the boat. The pump sucks it up and forces it out at high speeds through a nozzle located at the stern. Several benefits of this option include:

- Excellent maneuverability

- Higher speeds

- Less chance of obstructing lobster and fishing pits

- Reliability

- Shallow water operation

- Smooth rides

When using waterjet propulsion, you steer by changing the direction of the water stream as it leaves the jet unit. The boat will move in the direction opposite of where you point the stream.

Pod systems are perfect for large cruisers, semi-displacement trawler yachts, tugboats and cruise ships. Boats that use pod drivers have no rudders, and the pods rotate to steer the boat. The pods connect to the inboard engine and project down the hull, so there is no inefficient shaft angle. Advantages include:

- Impressive fuel efficiency

- Increased maneuverability when operating in tight spaces

- More space below the boat