- Metals & Electronics ›

Shipbuilding

Shipbuilding industry worldwide - statistics & facts

Impact of covid-19, short history of shipbuilding, key insights.

Detailed statistics

Shipbuilding capacity worldwide 2013-2026, by country

Regional breakdown of the global shipbuilding market - contracting

Global shipbuilding order book 2022, by vessel type

Company Insights Top 100 metals & electronics companies

- Toyota Motor

- Mercedes-Benz Group

Editor’s Picks Current statistics on this topic

Current statistics on this topic.

Water Transport

Number of merchant ships by type 2022

Maritime Transport

Largest shipbuilding nations based on gross tonnage 2022

Size of the global shipbuilding market 2020-2030

Related topics

Recommended.

- Water transportation industry

- Ocean shipping

- Container shipping

- Container carriers worldwide

- Green maritime shipping

Recommended statistics

- Premium Statistic Size of the global shipbuilding market 2020-2030

- Premium Statistic Number of active shipyards worldwide 2014-2022

- Premium Statistic Shipbuilding capacity worldwide 2013-2026, by country

- Premium Statistic Regional breakdown of the global shipbuilding market - contracting

- Premium Statistic Largest shipbuilding nations based on gross tonnage 2022

- Premium Statistic Number of merchant ships by type 2022

- Premium Statistic Age distribution of the world merchant fleet by vessel type 2022

Size of the global shipbuilding market in 2020 and 2021, with a forecast through 2030 (in billion U.S. dollars)

Number of active shipyards worldwide 2014-2022

Number of active shipyards worldwide from 2014 to 2022

Global shipbuilding capacity from 2013 to 2020, with a forecast for 2021 through 2026, by country (in million CGT)

Regional breakdown of the global shipbuilding market as of October 2021, based on contracting activity

Largest shipbuilding nations in 2022, based on deliveries (in million gross tons)

Number of ships in the world merchant fleet as of January 1, 2022, by type

Age distribution of the world merchant fleet by vessel type 2022

Age distribution of the world merchant fleet in 2022, by vessel type

- Premium Statistic Global shipbuilding order book 2022, by vessel type

- Premium Statistic Deliveries of new vessels worldwide by type 2021

- Premium Statistic New deliveries of bulk carriers worldwide by country 2021

- Premium Statistic New deliveries of oil tankers worldwide by country 2021

- Premium Statistic New deliveries of container ships worldwide by country 2021

- Premium Statistic New deliveries of chemical tankers worldwide by country 2021

- Premium Statistic New deliveries of general cargo ships worldwide by country 2021

- Premium Statistic Gross tonnage of cruise ship deliveries worldwide by region 2022

Global shipbuilding order book in 2022, by vessel type (units)

Deliveries of new vessels worldwide by type 2021

Deliveries of new vessels worldwide in 2021, by type (in 1,000 gross tons)

New deliveries of bulk carriers worldwide by country 2021

New deliveries of bulk carriers worldwide in 2021, by country of construction (in 1,000 gross tons)

New deliveries of oil tankers worldwide by country 2021

New deliveries of oil tankers worldwide in 2021, by country of construction (in 1,000 gross tons)

New deliveries of container ships worldwide by country 2021

New deliveries of container ships worldwide in 2021, by country of construction (in 1,000 gross tons)

New deliveries of chemical tankers worldwide by country 2021

New deliveries of chemical tankers worldwide in 2021, by country of construction (in 1,000 gross tons)

New deliveries of general cargo ships worldwide by country 2021

New deliveries of general cargo ships worldwide in 2021, by country of construction (in 1,000 gross tons)

Gross tonnage of cruise ship deliveries worldwide by region 2022

Gross tonnage of cruise ship deliveries worldwide in 2022, by region (in millions)

- Premium Statistic Leading Chinese shipbuilding companies on the Fortune China 500 ranking 2022

- Premium Statistic Domestic market share of shipbuilding companies South Korea 2022

- Premium Statistic China Shipbuilding Industry Company's revenue 2010-2022

- Premium Statistic China CSSC Holdings Ltd. revenue 2017-2022

- Premium Statistic DSME's sales revenue 2015-2022

- Premium Statistic Hyundai Heavy Industries - revenue 2018-2022

- Premium Statistic Samsung HI's revenue 2014-2022

Leading Chinese shipbuilding companies on the Fortune China 500 ranking 2022

Leading Chinese shipbuilding companies on the Fortune China 500 ranking in 2022, by revenue (in billion yuan)

Domestic market share of shipbuilding companies South Korea 2022

Leading shipbuilding companies in South Korea in 2022, based on domestic market share

China Shipbuilding Industry Company's revenue 2010-2022

Revenue of China Shipbuilding Industry Co.,Ltd (CSIC) from 2010 to 2022 (in billion yuan)

China CSSC Holdings Ltd. revenue 2017-2022

Revenue of the shipbuilding company China CSSC Holdings Ltd. from 2017 to 2022 (in billion yuan)

DSME's sales revenue 2015-2022

Daewoo Shipbuilding & Marine Engineering's sales revenue from 2015 to 2022 (in trillion South Korean won)

Hyundai Heavy Industries - revenue 2018-2022

Hyundai HI's sales revenue from FY 2018 to FY 2022 (in billion South Korean won)

Samsung HI's revenue 2014-2022

Samsung HI's sales from FY 2014 to FY 2022 (in billion South Korean won)

Shipbreaking

- Premium Statistic Number of commercial vessels dismantled worldwide 2013-2022

- Premium Statistic Average age of vessels scrapped worldwide 2013-2022

- Premium Statistic Number of commercial vessels scrapped worldwide by country 2022

- Premium Statistic Shipping tonnage sold for demolition worldwide 2014-2021

- Premium Statistic Shipping tonnage sold for recycling worldwide by vessel type 2021

Number of commercial vessels dismantled worldwide 2013-2022

Number of ocean-going commercial vessels dismantled worldwide from 2013 to 2022

Average age of vessels scrapped worldwide 2013-2022

Average age of vessels scrapped worldwide from 2013 to 2022

Number of commercial vessels scrapped worldwide by country 2022

Number of ocean-going commercial vessels dismantled in 2022, by country

Shipping tonnage sold for demolition worldwide 2014-2021

Reported shipping tonnage sold for demolition worldwide from 2014 to 2021 (in 1,000 gross tons)

Shipping tonnage sold for recycling worldwide by vessel type 2021

Reported shipping tonnage sold for ship recycling worldwide in 2021, by vessel type (in 1,000 gross tons)

Further reports Get the best reports to understand your industry

Get the best reports to understand your industry.

Mon - Fri, 9am - 6pm (EST)

Mon - Fri, 9am - 5pm (SGT)

Mon - Fri, 10:00am - 6:00pm (JST)

Mon - Fri, 9:30am - 5pm (GMT)

Boat Building in the US - Market Size, Industry Analysis, Trends and Forecasts (2024-2029)

Instant access to hundreds of data points and trends.

- Market estimates from

- Competitive analysis, industry segmentation, financial benchmarks

- Incorporates SWOT, Porter's Five Forces and risk management frameworks

- PDF report or online database with Word, Excel and PowerPoint export options

100% money back guarantee

Industry statistics and trends.

Access all data and statistics with purchase. View purchase options.

Boat Building in the US

Industry Revenue

Total value and annual change from . Includes 5-year outlook.

Access the 5-year outlook with purchase. View purchase options

Trends and Insights

Market size is projected to over the next five years.

Market share concentration for the Boat Building industry in the US is , which means the top four companies generate of industry revenue.

The average concentration in the sector in the United States is .

Products & Services Segmentation

Industry revenue broken down by key product and services lines.

Ready to keep reading?

Unlock the full report for instant access to 30+ charts and tables paired with detailed analysis..

Or contact us for multi-user and corporate license options

Table of Contents

About this industry, industry definition, what's included in this industry, industry code, related industries, domestic industries, competitors, complementors, international industries, performance, key takeaways, revenue highlights, employment highlights, business highlights, profit highlights, current performance.

What's driving current industry performance in the Boat Building in the US industry?

What's driving the Boat Building in the US industry outlook?

What influences volatility in the Boat Building in the US industry?

- Industry Volatility vs. Revenue Growth Matrix

What determines the industry life cycle stage in the Boat Building in the US industry?

- Industry Life Cycle Matrix

Products and Markets

Products and services.

- Products and Services Segmentation

How are the Boat Building in the US industry's products and services performing?

What are innovations in the Boat Building in the US industry's products and services?

Major Markets

- Major Market Segmentation

What influences demand in the Boat Building in the US industry?

International Trade

- Industry Concentration of Imports by Country

- Industry Concentration of Exports by Country

- Industry Trade Balance by Country

What are the import trends in the Boat Building in the US industry?

What are the export trends in the Boat Building in the US industry?

Geographic Breakdown

Business locations.

- Share of Total Industry Establishments by Region ( )

Data Tables

- Number of Establishments by Region ( )

- Share of Establishments vs. Population of Each Region

What regions are businesses in the Boat Building in the US industry located?

Competitive Forces

Concentration.

- Combined Market Share of the Four Largest Companies in This Industry ( )

- Share of Total Enterprises by Employment Size

What impacts market share in the Boat Building in the US industry?

Barriers to Entry

What challenges do potential entrants in the Boat Building in the US industry?

Substitutes

What are substitutes in the Boat Building in the US industry?

Buyer and Supplier Power

- Upstream Buyers and Downstream Suppliers in the Boat Building in the US industry

What power do buyers and suppliers have over the Boat Building industry in the US?

Market Share

Top companies by market share:

- Market share

- Profit Margin

Company Snapshots

Company details, summary, charts and analysis available for

Company Details

- Total revenue

- Total operating income

- Total employees

- Industry market share

Company Summary

- Description

- Brands and trading names

- Other industries

What's influencing the company's performance?

External Environment

External drivers.

What demographic and macroeconomic factors impact the Boat Building in the US industry?

Regulation and Policy

What regulations impact the Boat Building in the US industry?

What assistance is available to the Boat Building in the US industry?

Financial Benchmarks

Cost structure.

- Share of Economy vs. Investment Matrix

- Depreciation

What trends impact cost in the Boat Building in the US industry?

Financial Ratios

- 3-4 Industry Multiples (2018-2023)

- 15-20 Income Statement Line Items (2018-2023)

- 20-30 Balance Sheet Line Items (2018-2023)

- 7-10 Liquidity Ratios (2018-2023)

- 1-5 Coverage Ratios (2018-2023)

- 3-4 Leverage Ratios (2018-2023)

- 3-5 Operating Ratios (2018-2023)

- 5 Cash Flow and Debt Service Ratios (2018-2023)

- 1 Tax Structure Ratio (2018-2023)

Data tables

- IVA/Revenue ( )

- Imports/Demand ( )

- Exports/Revenue ( )

- Revenue per Employee ( )

- Wages/Revenue ( )

- Employees per Establishment ( )

- Average Wage ( )

Key Statistics

Industry data.

Including values and annual change:

- Revenue ( )

- Establishments ( )

- Enterprises ( )

- Employment ( )

- Exports ( )

- Imports ( )

Frequently Asked Questions

What is the market size of the boat building industry in the us.

The market size of the Boat Building industry in the US is measured at in .

How fast is the Boat Building in the US market projected to grow in the future?

Over the next five years, the Boat Building in the US market is expected to . See purchase options to view the full report and get access to IBISWorld's forecast for the Boat Building in the US from up to .

What factors are influencing the Boat Building industry in the US market trends?

Key drivers of the Boat Building in the US market include .

What are the main product lines for the Boat Building in the US market?

The Boat Building in the US market offers products and services including .

Which companies are the largest players in the Boat Building industry in the US?

Top companies in the Boat Building industry in the US, based on the revenue generated within the industry, includes .

How many people are employed in the Boat Building industry in the US?

The Boat Building industry in the US has employees in United States in .

How concentrated is the Boat Building market in the United States?

Market share concentration is for the Boat Building industry in the US, with the top four companies generating of market revenue in United States in . The level of competition is overall, but is highest among smaller industry players.

Methodology

Where does ibisworld source its data.

IBISWorld is a world-leading provider of business information, with reports on 5,000+ industries in Australia, New Zealand, North America, Europe and China. Our expert industry analysts start with official, verified and publicly available sources of data to build an accurate picture of each industry.

Each industry report incorporates data and research from government databases, industry-specific sources, industry contacts, and IBISWorld's proprietary database of statistics and analysis to provide balanced, independent and accurate insights.

IBISWorld prides itself on being a trusted, independent source of data, with over 50 years of experience building and maintaining rich datasets and forecasting tools.

To learn more about specific data sources used by IBISWorld's analysts globally, including how industry data forecasts are produced, visit our Help Center.

Deeper industry insights drive better business outcomes. See for yourself with your report or membership purchase.

Discover how 30+ pages of industry data and analysis can give you the edge you need..

Yachting Monthly

- Digital edition

Boat building: what will yachts be made from in the future?

- Sam Fortescue

- December 17, 2021

Sam Fortescue shines a light on boat building jargon and looks into a future devoid of fibreglass

Building with pre-preg materials is efficient, but the hull must be 'cooked' at a precise temperature to cure it. Credit: Eva-Stina Kjellman

The end of GRP? Sam Fortescue looks at past, present and future boat building materials

Glance at a brochure for a new boat or walk the pontoons at the Southampton show and you may have come across some terms that didn’t mean much to you.

The art of boat building is as recognisable as ever, but the science of it is constantly developing. New materials and new techniques can make it hard to compare like with like.

Take wood, for instance: the material of boatbuilding choice for millennia.

There are still plenty of wooden boat-builders out there, labouring away in dingy sheds and halls to craft pilot cutters, rowing skiffs and other emblematic vessels of yesteryear.

But perhaps the best known of the wooden boatbuilders is Spirit Yachts in Ipswich, building thoroughly modern boats – in composite wood.

The Spirit 44E is a ‘zero carbon’ cruising yacht. Credit: Richard Langdon

‘Certainly we use epoxy resin to bond the components together, but the amount of resin used is minute compared to GRP or carbon,’ says founder and head designer Sean McMillan.

‘Both carbon-fibre and GRP rely totally on being saturated with a high density of polyester or epoxy resins to impart structural integrity. Wood, whilst also a linear fibre material, is cross-linked with a cellular structure entirely created by nature and has full structural integrity in its own right.’

In fact, the 1.6-tonne Spirit 30 daysailer employs just 73kg of resin and 12.2kg of hardener in its entire construction.

‘In 20 years’ time, when GRP has become socially unacceptable – not to mention any future end-of-life legislation – who knows, we may look back and see the last 60 years of GRP boats as a historical niche,’ finishes McMillan defiantly.

Another example is racy French builder RM Yachts, whose boats are famously swift, with offshore hulls designed by Marc Lombard.

And yet they are built in plywood and epoxy.

Thought every Spirit yacht us built of wood, it is a composite of glue and epoxy sheathing.

It is flexible, robust and far more sustainable than standard glass-reinforced plastic.

Sheets of laser cut Okoumé plywood up to 22mm thick are bent around a mould and epoxied to plywood structural members.

The whole lot is also epoxy sheathed for longevity.

It’s a technique which means that the brand-new RM 1380 is 9.8 tonnes light – slightly less than the comparable X4-6 from X-Yachts.

‘Plywood is the soul of an RM. It a very useful material, allying a good stiffness with lightness – perfect for building the hull and the structure,’ says head of engineering Edouard Delamare.

‘But plywood is nothing without epoxy, because it ensures the waterproofing – vital in a marine environment.’

Boat building using glass-reinforced plastic

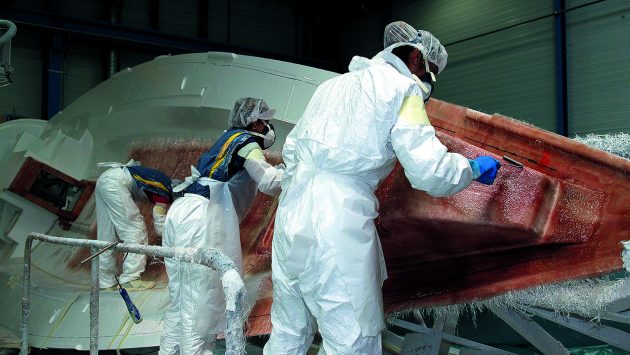

Many series production yards, from Beneteau to Bavaria , still use the most basic form of wet lay-up – splurging resin on to mats of glassfibre with a roller to get them well wetted out before laying down the next layer of glass.

It is very hard to control how much resin is applied and there are often air pockets between layers.

For this reason, hulls built this way tend to be overbuilt and heavier.

RM Yachts is unique in building its offshore yachts in plywood and epoxy

Polyester is the cheapest and most commonly used resin, but it can bond with water, creating the problem of osmosis.

That’s why isopthalic gelcoats are applied to the outside of the hull, to act as an effective barrier to moisture.

Vinylester creates many more bonds than polyester and is reckoned to be up to three times stronger, but it costs more too.

And epoxy is the best performing resin of all, used only in high-quality lay-ups. All are pretty toxic, and sport the ‘dead-fish’ icon on the side of the tin.

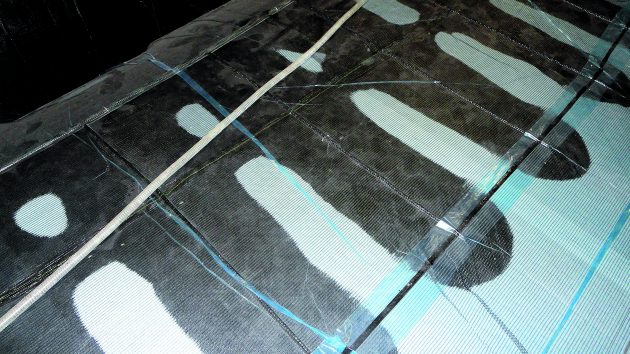

When vacuum infusion emerged as an industrial technique in 1990, it allowed boatbuilders to use less resin and spread it more evenly around the finished panel for greater strength.

But it generates a lot of waste, because each infused part has to be prepared with a host of plastic layers.

Besides the plastic of the vacuum bag itself, there’s a breather layer to distribute the resin and a peel ply to stop it sticking to the infused part; a thick bead of sealant tape; disposable feeder tubes are required every few inches, and many of the vacuum tubes must also be binned.

The technology has not stood still, though, and there are now reusable vacuum bags made from inert silicon, for instance.

Some bags have the mesh structure necessary to spread the resin built in, while the aerospace sector has pioneered the use of PTFE membrane that stops resin clogging up the vacuum pump side of the system.

Sweden’s Arcona builds its fast cruisers using vacuum infusion, and has for many years.

Hand lay-up is a process that has changed little over the years of boat building

But in order to add strength and stiffness, it laminates in a steel support frame amidships to transfer the loads from the rig into the keel.

Improvements in lamination techniques mean that the boats are lighter than ever.

Late Arcona designer Stefan Qviberg said the current Arcona 40 displaced a whole tonne less than its equivalent a decade earlier.

Other boat builders use other types of reinforcing for the high-load areas of the hull.

Aramids like Twaron and Kevlar often feature, as do selective areas of carbon-fibre on stringers and around keel bolts and chainplates.

High-end yacht builder Baltic uses carbon reinforcing, for instance, to add strength without extra weight.

Vacuum infusion uses less resin but creates a lot of plastic waste

Performance catamaran brand Catana likewise uses Twaron and carbon in its lay-up to save hundreds of kilos; some 700kg in the old Catana 47.

Some claim that aramid reinforcing makes a hull safer, for example in the event of collision with a container, but others refute this.

Naturally enough, carbon is still the ultimate performance material because of its blend of strength, stiffness and light weight.

It is also prohibitively expensive relative to other fibres and very resource-intensive to produce, as it requires temperatures up to 3,000º C and a plastic feedstock.

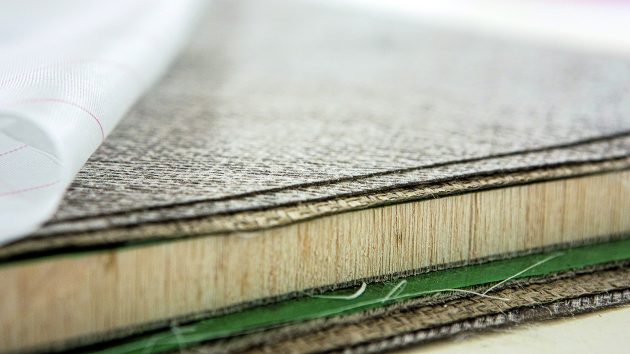

The bulk and waste of the infusion process has led to another step forward in the form of so-called pre-preg materials, where the sheets of fibre used to strengthen the hull come ready-coated with a pre-catalysed form of the resin that reacts very slowly at room temperature.

Instead of needing to mix epoxy with hardener and reduce its viscosity with toxic styrene to draw into the mould, a precisely-controlled curing process activates and sets the resin.

The result is a stronger, lighter laminate than can be produced through wet lay-up.

Gurit’s SPRINT system goes a step further by sandwiching a thin film of heat-activated resin between two layers of fibre.

Windelo uses basalt fibre to strengthen its hulls during the boat building process. It is said to be much less carbon intensive than using glass

The advantage of this is that the fibres remain dry until curing so air can be more easily removed under vacuum to produce a laminate with a void content of less than 0.5%.

Baltic Yachts uses this technique, building an oven around its hulls to cure them.

‘With one or two exceptions, we haven’t infused a boat for some time,’ says CEO Henry Hawkins.

‘Using Sprint and pre-preg materials saves weight compared to vacuum infusion. With hand lay-up, generally more resin is mixed than needed and a lot gets discarded. This is the same with infusion where resin is lost or wasted in the plastic hoses and pipes and breather film and within the distribution channels.’

Continues below…

The dirty truth about teak

Teak is beloved by boat owners and shipyards for decking and yacht building, but any claims that it is sustainably…

ON TEST: Spirit 44e – the sustainable future of sailing?

A wooden boat that blazes a trail for modern technology and sustainability sounds too good to be true. Theo Stocker…

What’s the future for derelict GRP boats?

With 9,000 GRP boats abandoned in Europe each year, finding disposal solutions isn't easy. Could new technologies be the answer?…

Even at this sharp end of the composite business, rapid advances are being made – driven by aerospace and Formula One.

‘We can now take away the expensive autoclaves and ovens – they can cure at ambient or 40-60ºC,’ says Ashley Parkinson, a research engineer with the UK National Composites Centre.

‘It’s a more expensive process to use, but in the high-performance market, it’s worth it.’

Greener composites

Now, there is nothing particularly sustainable about producing glassfibre – a technique that involves heating raw silica to 1,370º C, then pultruding the molten strands onto a bobbin.

You can use some recycled glass to lower your emissions, but it is an energy intensive process and it is very hard to extract the raw materials from end-of-life fibreglass.

Swiss supplier Bcomp tested alternative natural fibres 10 years ago, when it was a start-up in a garage.

‘Flax turned out to be the best in terms of mechanical properties, soil usage, water requirements and overall performance,’ explains marine and industry manager Paolo Dassi.

It actually locks up carbon rather than producing it – as much as 500g of CO2 per kilogram of flax.

Precise cutting is key to reducing fibre wastage in boat building

‘The plant acts as a CO2 sink during its growth. This completely offsets the CO2 emissions of the manufacturing stages.’

Bcomp’s extraordinary growth began when it managed to process the flax stems to be of uniform size and flatness, replicating the grades possible using glassfibre.

Its AmpliTex product is available as a unidirectional, stitched biaxial or woven twill, ranging from 200-500gsm.

In lamination it is 50% stiffer than glass and just a little weaker, making it an ideal substitute.

Couple this with an extra flax mesh called PowerRibs, and you end up with a composite that closely resembles carbon, but with just 25% of the emissions.

AmpliTex has already been used in niche boat building projects, including the glorious Flax 27 daysailer by Green Boats of Bremen, which sports cork decking.

Foam sandwich hull construction (green) or balsa core (wood) is much stronger, for little extra weight. Credit: Graham Snook/Yachting Monthly

It was a key part of the lay-up of the new Café Racer 68 from Baltic. Although her hull is in carbon, 50% of the structural members were in flax composite.

France’s Windelo has taken a different tack in its catamarans.

It uses basalt fibre – made from melted volcanic rock – which ‘is slightly stronger than E-glass and just one-10th as carbon intensive to produce and use’.

Its first 50-footer has a hull that also features a recycled PET foam core for strength and stiffness. But it is not just the fibre that is being decarbonised.

So-called ‘green epoxies’ have been developed, where a significant chunk of the synthetic oil-derived molecules of the resin are replaced by bio-sourced molecules.

Gurit’s Ampro for hand laminating is 40% bio derived, for instance.

Green Yachts focuses on environmentally-friendly boat building techniques. Its Flax 27 is built of sustainable flax fibre

And the ProSet range from West Systems includes epoxies containing up to 30% bio molecules.

They can essentially just be dropped into any process that would have been suitable for the equivalent synthetic resin.

‘Any customer that is familiar with epoxy processing, vacuum consolidation or post curing will be very familiar with the process,’ says David Johnson of Wessex Resins, European manufacturer for West.

‘Even wet lay-up with no vacuum bagging.’

There is a modest cost increase, but it amounts to less than 25% compared to a standard epoxy, and a drop in the ocean of the boat’s overall build.

‘Bio-based epoxies are more expensive because there’s more sophisticated chemistry involved,’ says Johnson.

Pre-preg flax fibres being laid up around a balsa core

‘Compared to building a boat in vinylester or polyester, you can use slightly less material because of the superior qualities of epoxy. The end cost differences are negligible and there are benefits in lighter weight: you become more efficient, and the loads are less.’

Suppliers like Gurit are also finding ways to substitute the synthetic foam core used in sandwich hull construction.

Standard foam is made of virgin PVC, with all the associated environmental pitfalls.

Gurit has developed more renewable alternatives using up to 100% recycled PVC and balsa wood.

Builders from Arcona and X-Yachts to Bali and Gunboat catamarans use foam cores in their lay-up to build boats that are stiffer and lighter than they would be otherwise.

Away from composites

Some innovative new boat builders are going in another direction altogether, eschewing the by-now traditional GRP for something that can be genuinely reused repeatedly.

Start-up Vaan is building its 42ft R4 catamaran out of a grade of aluminium alloy commonly used in window frames and road signs, so up to 60% of the hull is already recycled.

‘There’s no way to distinguish it from virgin material,’ says Vaan founder Igor Kluin.

Vaan uses a high proportion of recycled aluminium to build its hulls, which can then be easily recycled

It hasn’t been easy to secure supplies, however. That’s partly because window frames last for 50 years or more and also competition with other sectors.

‘In the short term the costs are higher because there are so many people jumping on the bandwagon, but it has only 5% of the energy use of virgin alloy, so in the end it should be cheaper.’

Vaan’s novel approach to sourcing more sustainable materials extends to the interior finish as well.

It uses a pineapple leaf fabric instead of leather, plentiful European poplar for cabinetry, cork instead of teak decking and recycled PET.

Greener boat building: A hull made from recycled aluminium

Parts of the boat are 3D printed – something that higher end brands are doing more and more of.

‘Recycled industrial PET is being 3D printed for the back of the Vaan spoiler because it produces a lower volume than moulding,’ says Kluin.

‘We want to see if it can become load bearing. We’re also 3D printing with aluminium, too. It’s useful for smaller structural elements that are hard to reach and would traditionally have been milled.’

Recyclability of boat building materials

Besides wood, all forms of composite suffer from the same problem; at end of life, it is very difficult to separate the component materials for re-use.

This is why using materials such as steel or aluminium can make sense, despite the higher environmental cost of the virgin metal. They can be reused repeatedly.

The composite recycling systems developed to date, which include pyrolysis, burning and shredding, are all unsatisfactory because of the energy intensity of the processes or the fact they yield a lower quality material that has to be downcycled.

In principle, it is possible to use resins that melt again at high temperatures and can be collected, refined and reused.

Elium resin from Arkema is capable of exactly that, and is already being used in recyclable wind turbine blades.

Laminate are expensive to separate for re-use. Credit: Rob Wilkinson/Alamy Stock Photo

They even built a 6.50m Mini Transat boat from it.

The process also yields reusable glass, but carbon and flax don’t support the heat: carbon loses as much as two-thirds of its strength and flax simply combusts.

However, an Australian study has shown how carbon-fibre composite can first be heated without oxygen in a pyrolysis chamber to burn off resin, then oxidised to yield carbon-fibre with most of the strength of virgin fibre but only 10% of the environmental impact.

Cured laminates can also be separated using a chemical process proven in the lab at the National Composites Centre, with a big vat of acetic acid.

Portsmouth University is researching enzymes to decompose plastic, starting with plastic bags.

The approach could eventually handle boats as well.

‘You have to find the right enzyme that works for snipping the molecules of a particular polymer. Practically, it’s a decade away,’ says Ashley Parkinson of the NCC.

Yachting World

- Digital Edition

The future of boatbuilding: a greener approach

- Rupert Holmes

- January 5, 2022

Sustainable materials and disruptive trends are needed to shake up the boatbuilding industry and to make the future of boatbuilding greener. Rupert Holmes reports

When enjoying a glorious day on the water it’s easy to assume sailing must be one of the most sustainable activities on the planet. Yet in many respects the marine industry is decades behind other sectors. Most new yachts use tonnes of virgin plastic that can’t be recycled – a staggering 250,000 tonnes of fibreglass is discarded every year in Europe.

By contrast, more than 80% of the material of scrap cars has been required to be recycled since 2006. Perhaps the closest to this circular economy approach in boatbuilding is Vaan, a new Dutch brand, which has just launched its first aluminium 42ft R4 model. The hulls are made from over 60% recycled aluminium material and the whole boat is completely recyclable.

The Greenboats Flax 27 uses woven flax fibres beneath a clear resin for its main structures.

Of course composite structures, especially cored panels, are inherently more difficult to recycle than the stripped-out bodyshell of a car. A notable exception is that of the roto-moulded hulls of small boats – RS Sailing, for instance, uses a polyethylene material for this purpose, which is easy to recycle.

Fortunately, manufacturers of raw materials such as resin and structural fibres are investing huge amounts in developing more sustainable options. Those building boats using these developing materials tend to be innovative smaller businesses.

Green Boats’ Flax 27 daysailer, for example, highlights the woven structural flax fibres behind clear resins, creating a unique appearance.

But Baltic Yachts has also used flax fibres in a number of projects, including for much of the lay-up of the recently launched 68ft Baltic Café Racer .

The Baltic Café Racer is built using flax fibres

This use of natural materials and pairing them with bio-resins (generally made using by-products from growing sugar cane) is a big step forward. The carbon emissions required to produce the fibres are dramatically reduced, while the resins are less noxious than standard polyester, vinylesters or epoxies.

Volcanic potential

Basalt fibre also offers excellent potential: this volcanic rock can be crushed, then heated to very high temperatures and extruded through microscopic nozzles to form continuous structural fibres that are stronger than steel.

Despite the high temperatures involved the process is a simple one. It uses a single raw material and only 5kWh of power is needed to produce each kilogramme of finished fibre – which makes it more sustainable than glassfibre.

This is the favoured material of Les Sables d’Olonne based Innovation Yachts , which has already produced a 91ft superyacht, an IMOCA 60 -style vessel aimed at breaking round the world records, and the world’s first recyclable solar-electric boat built from composite materials, the LBV35 catamaran .

Windelo, a new multihull yard in the south of France, has produced its first 50ft and 54ft catamarans using a composite sandwich of basalt fibre and PET foam, the latter made from recycled plastic bottles.

It says that, compared to traditional glassfibre methods, this reduces carbon emissions by nearly 50%. Neel Trimarans is also experimenting with many fibre materials such as basalt and linen/flax combinations, bio-resins and PET cores, and is already incorporating these materials in non structural parts of its production yachts.

Use less Materials

Green Boats founder Friedrich Deimann points out that reducing the amount of material used is also a critical element of sustainable manufacture. Green Boats is helping the IMOCA 60 class to produce the many small components these boats use in a more sustainable manner.

The transom escape hatch for 11th Hour Racing ’s new boat, for instance, is made of flax and bio-resin. More time spent on structural engineering means it meets the same structural criteria as carbon hatches, yet is 20% lighter. Equally, the RS Aero dinghy weighs roughly the same as an Optimist, making it 50% lighter than many single-handers of its size.

11th hour racing in the 2021 Fastnet Race Photo: James Tomlinson

Using half the quantity of material halves the greenhouse gas emissions associated with raw materials, but can be difficult to achieve. Vacuum-bagging has been used to optimise resin use for more than 25 years, to create stiffer, stronger, and lighter structures, but the excess resin is effectively wasted once mixed, and it requires vast amounts of single-use plastic.

For smaller components Green Boats gets around this with a panel press which does the same task with vastly reduced waste. Dutch company Curveworks uses adaptive moulds to create cored composite structures that can be ‘stitched’ together into a larger hull.

The Arkema 4 Ocean 50 trimaran launched in 2020 uses recyclable Elium thermoplastic resin

The fundamental problem with resins currently used in boatbuilding, is that it’s impossible to separate them from the structural fibres, which makes it so difficult to recycle. Usually the only viable option is to grind up the composite material to use as a filler in concrete.

French company Arkema has developed a thermoplastic resin called Elium that can be used in much the same way as conventional boatbuilding resins, yet can be fully recovered at the end of its life and used to produce fresh material with identical properties to the virgin resin.

The process also allows the salvaged structural fibres to be reused – important for carbon fibre which requires a huge energy input to create virgin fibre.

A further advantage of Elium is that, unlike conventional boatbuilding resins, thermoplastics can be melted in a controlled fashion that allows elements to be welded together.

Isle of Man-based Exo Technologies has developed a patented material called DANU. This can also be recycled at the end of life and the company calls it a ‘circular composite material’. It’s a combination of styrene-free resin and sustainable fibres that’s stronger and lighter than fibreglass, yet less brittle than carbon fibre. Exo Tech’s subsidiary Ultimate Boats has plans for an offshore 32ft raceboat that would use DANU composite.

The Spirit 30 is Spirit Yacht’s most sustainable yet: a combination of exemplary workmanship and eco construction

An older technology also deserves mention in this context – cold moulded or strip planked construction where layers of timber are glued together with the grain running at different angles, creating a light and stiff structure.

It’s been a popular construction method for low production run yachts for almost 40 years and is how Spirit Yachts continues to build. When combined with bio-resins, this can be a low carbon, sustainable way of producing a boat.

If you enjoyed this….

Yachting World is the world’s leading magazine for bluewater cruisers and offshore sailors. Every month we have inspirational adventures and practical features to help you realise your sailing dreams. Build your knowledge with a subscription delivered to your door. See our latest offers and save at least 30% off the cover price.

Elevating Boat Builders Through an Effective Collaborative Platform

Gain agility, responsiveness and competitiveness in boat building with the 3D EXPERIENCE® all-in-one collaborative platform.

The rising global interest in leisure boating activities has created new demands for leisure boats. Currently valued at about USD 8.91 billion, the leisure boat and yacht building industry is set to grow 5.8% per year from 2023 to 2030, heralding a bright future.

This dynamic growth, however, presents boat builders with a herculean task to unlock new horizons of innovation at great speed. The boat building process is highly complex and time-consuming, involving multidisciplinary stakeholders — with some still operating in silos. Pioneering innovative, sustainable designs demands a profound understanding of customer needs, in-depth engineering knowledge and state-of-the-art tools. Innovation becomes key to bringing boats with timeless craftsmanship and sophisticated technology to the market quickly and affordably.

Discover the challenges of boat building and how Dassault Systèmes' all-in-one collaborative solution, powered by the 3D EXPERIENCE® platform , helps boat builders overcome them. Click on the steering wheel to begin.

Improve Efficiency of Small and Medium Boat Builders

To master a boat's design and engineering, you can rely on Dassault Systèmes' all-in-one solution that seamlessly integrates every step of the boat building process. With the 3D EXPERIENCE platform, you can connect design, engineering, simulation and manufacturing steps in a single unified platform to strengthen efficiencies through:

Integrated design and engineering

Integrating multidisciplinary systems enables builders to seamlessly test and validate breakthrough designs, streamline workflows and increase accuracy. The combined modeling and simulation approach allows testing of various scenarios and performance evaluation for faster iteration and decision-making, saving time and resources. With the 3D EXPERIENCE platform, builders can share ideas and expertise and explore multiple what-ifs to improve design, quality, performance and safety — thus, creating vessels that excel in form and function.

End-to-end collaboration

Collaboration breaks down silos to create an environment of shared expertise and streamlined processes. This means accessing real-time design, engineering and manufacturing data to collaborate faster with suppliers, contractors and customers. With an updated and accurate single source of information, builders gain agility and transparency to track progress, identify bottlenecks and swiftly mitigate design, material and regulatory compliance issues while maintaining IP protection.

Acceleration from concept to manufacturing

By enabling collaboration on a virtual twin , all stakeholders can rely on real-time information across design, engineering, manufacturing and project management. This allows builders to validate the design intent and engineering choices much earlier and avoid late changes, which is key to delivering on time and on budget. It also improves the reusability of knowledge and designs across projects for better responsiveness to future market demands. The model created and developed from early stages can be leveraged for communication and marketing materials to support go-to-market strategies.

Unlock the Benefits of an All-in-One Solution in Boat Building

Accelerate innovation in boat building with an all-in-one collaborative solution.

Sail the Next Waves of Transformation

The 3D EXPERIENCE platform enables boat builders to speed up manufacturing with precision and efficiency. With seamless integration of processes from end to end, boat builders can unleash new possibilities to:

- Build yachts right the first time — reducing costly errors, minimizing rework and preventing costly delays

- Facilitate product diversification, leading to a bigger market share and faster go-to-market time

- Optimize shipyard workforce and resources to avert delivery disruptions

- Exceed expectations through customer feedback data, expand to untapped markets and fuel business growth

I’d go as far as to say we are working 50% faster with the virtual twin as we don’t have to create a physical mock-up. It also means our approach is more sustainable since we are not wasting materials.

Hallberg-Rassy

Swedish yacht manufacturer Hallberg-Rassy has implemented the 3D EXPERIENCE platform on the cloud to deliver its world-renowned sailing yachts on time and meet its customers' expectations. By choosing the Sea Boat Builder industry solution experience, the company now has a single environment where all designers can collaborate on a virtual twin.

Dassault Systèmes' all-in-one cloud solution provides end-to-end convenience — taking care of SaaS, PaaS and IaaS all in a go. Flexible and scalable, boat and yacht builders can expand their capabilities to support future business demands, push engineering boundaries and chart market growth confidently into the future.

Discover more

Explore our industry solution experiences.

- Subscribe English English Français 日本語 한국어

- All industries

- Aerospace & Defense

- Architecture, Engineering & Construction

- Business Services

- Cities & Public Services

- Consumer Packaged Goods & Retail

- Home & Lifestyle

- Industrial Equipment

- Infrastructure, Energy & Materials

- Life Sciences & Healthcare

- Marine & Offshore

- Transportation & Mobility

- Company News

- Design & Simulation

- Manufacturing

- People Profiles

- Sustainability

- Thought Leadership

- Virtual Experience

- Workforce of the Future

Leisure boat builders sail towards sustainability

Marine & Offshore June 23, 2023

Table of contents

Keeping pace with sustainable consumers and regulations

Swapping fiberglass and plastics for bio-resins, the rise of alternative propulsion, digitalizing boat development.

As pressure intensifies for boat builders to do away with carbon intensive materials and production methods and reduce their reliance on fossil fuels, they must develop a new generation of leisure boat. Success relies on their ability to innovate and master the innate complexity that comes with integrating new technologies and materials.

Around 40% of millennials are concerned about the environmental impact of their boats and 60% are interested in alternatively fueled recreational boats. They’re willing to pay more for sustainability too. In a McKinsey survey of recreational-boat buyers, up to 73% of consumers said they would be likely to opt for a more expensive, electric option over a boat with an internal-combustion engine.

Industry bodies such as the International Maritime Organization (IMO) – the United Nations (UN) agency responsible for regulating shipping and safeguarding our oceans – are also stepping up sustainability measures.

On World Oceans Day 2023 , IMO highlighted what more needs to be done for the industry to reach its target of reducing carbon emissions by at least 40% by 2030 and phasing them out entirely by the end of the century. In the short term, the UN body encourages research and development activities focused on marine propulsion, alternative low-carbon and zero-carbon fuels, and innovative technologies to further enhance the energy efficiency of ships.

Until now, materials such as fiberglass, synthetic resins and virgin plastics have been popular choices in boat construction. Yet they are also among the most carbon intensive and polluting materials produced today. In Europe alone, over 250,000 metric tons of glass fiber is sent to landfill. Exciting breakthroughs in recyclable bio-resins promise to change that.

Natural resins using hemp, basalt and flax fibers are just some of the innovations making their way into the latest vessel prototypes. These recyclable fibers perform as well as more traditional materials in terms of durability, lower density and vibration control. They are also nontoxic and require far less energy to produce: their carbon footprint is up to 80% less than that of glass fiber.

Meanwhile bio-resins used for bonding in boat construction and other areas of manufacture, such as laminating yacht decks, have a 50% lower carbon footprint and consume half the amount of energy and water than an average non-bio-based resin. What’s more, these materials can all be repurposed and recycled back into the boat building industry when the lifespan of a vessel has run its course.

However, because these new materials don’t possess the exact same characteristics as carbon or glass fiber, boat builders need to be able to test bio-resins on the virtual twin at an early design stage. This allows designers and engineers to make the right choices and trade-offs. A combined modelling and simulation solution also helps bridge the gap between design and simulation to optimize the use of these new materials.

Electric and hybrid propulsion technologies are already appearing on leisure boats and yachts as battery technology continues to catch up with boating’s higher-load requirements. It’s leading to rising demand to convert existing vessels to electric propulsion, which involves replacing or retrofitting existing propulsion systems with electric motors, batteries and associated control systems. The specific installation process and feasibility depends on the boat’s size, design, and available space for battery storage. Specialized marine electric conversion companies handle these assessments, select appropriate equipment, and carry out the conversion process.

A unified digital platform facilitates this complex task by supporting seamless collaboration between different stakeholders, bringing them together around a unified digital model. This way, it becomes easier to visualize the integration.

To further improve energy efficiency, leisure boats are also being fitted with solar panels and wind generators. A renewable source of energy, marine solar panels are proving cost effective and reliable. Well suited to life at sea, they are highly durable and, unlike a generator, produce no excess heat or sound pollution, creating a positive experience for both passengers and the planet.

As green credentials move higher up the agenda, boat and yacht builders will need to tap into digital technologies to make their product development processes more efficient and support them to bring innovative vessels to market faster. The ever-growing boat building ecosystem, involving a large number of internal and external stakeholders, generates vast amounts of information and requires everyone involved to work and collaborate in the same environment, synchronize tasks, and seamlessly move from the design to the construction phase. Using the Sea Boat Builder industry solution on the 3D EXPERIENCE platform helps them to work closely in real time and maximize productivity throughout each project.

Leisure boat and yacht builders will also need to create completely sustainable vessels from the ground up and monitor and measure their environmental impact throughout their entire lifecycle. Lifecycle assessment (LCA) solutions such as Sustainable Innovation Intelligence on the 3D EXPERIENCE platform provide the capabilities to do just that. It allows boat builders to identify the most sustainable materials, evaluate the environmental implications of every component, measure energy consumption in manufacturing processes and take responsibility for the end of life of every vessel as the world moves towards a circular economy .

The inevitable shift to a decarbonized marine industry means that it’s now up to boat builders to demonstrate they’re tackling sustainability from all angles, covering every stage of the product development lifecycle. Early action presents an opportunity to gain an edge over the competition and win new customers and investors while becoming more resilient to increasingly stringent regulations and carbon taxes. Powered by the 3D EXPERIENCE platform, they can do just that – and potentially reinvent the entire notion of recreational boating in the process.

Become more agile, responsive and competitive in boat building with the 3D EXPERIENCE all-in-one collaborative platform.

Discover more >>

Stay up to date

Register here to receive a monthly update on our newest content.

Yacht and Boat Building

Who is this course suitable for, whether you are in the early stages of your career, nearing the end and looking for a retirement project, on sabbatical leave or currently working within the maritime industry, this course will stretch and challenge you and most importantly, bring you closer to completing a yacht or boat build project..

About the Course

The dream of every man and woman with an interest in the sea is to ultimately build their own boat.

Trans-oceanic sailor Jimmy Cornell once wrote, “The planning stage of a cruise is often just as enjoyable as the voyage itself, letting one’s imagination loose on all kinds of possibilities. Yet translating dreams into reality means a lot of practical questions have to be answered.”

The Yacht and Boat Building course is constructed to guide those dreams to fruition and further educate you on the intricacies involved with building your own boat. Incorporating aspects of the decision-making, management and construction processes, you will be a step closer to achieving your dreams of building your own vessel.

“Whenever your preparations for the sea are poor; the sea worms its way in and finds the problems” – Francis Stokes. This course, with its easy to follow steps, will provide you with knowledge on various boat building materials, and highlight the various skills that are paramount to the successful construction of your boat.

This course is not intended to be the solitary element in the building of your boat, but rather best utilised as an overall guide as to what steps you need to take in order to pursue your ambition. We would recommend that this course would be most effective in conjunction with further knowledge and experience in building your own boat.

Course Structure

The course consists of 10 modules. All students are required to successfully complete and pass the module assignments. Diploma students will also be required to sit and pass a final examination.

1. Deciding On A Boat To Build

- Assessing your needs and inspirations

- Different classes of a self-build

- Basic Yacht Designs

- Basic Motor Boat designs

- Basic construction types

- The build facility

- Yacht designers

2. Managing The Build Process

- Where to Build

- Workshop/Yard requirements

- Budgeting and Costs

- Project Management

- Sourcing Parts

- Buy or Lease/machinery and tools

- BOM’s/detailed costs

3. Documentation/Training

- CE Certification

- Type Approval/Licensing

- Legal Requirements

- VAT/ Goods Service Tax etc

- Warranties/Manuals

- Learn to Sail

- Basic Safety at Sea

4. Constructing in Steel/Aluminium

- History/Background

- Construction Techniques

- Designers Plans

- Health & Safety

- Skills required

- Sub-contracting/ machinery & tools required

- Paints coatings/protective systems

5. Mechanical Systems

- Steering & rudders

- Water makers

- Pumping Systems

- Tools required & sub-contracting

- Documentation and conclusion

6. Basics of Yacht/Boat Building

- To loft or not?

- Basics of lofting

- Advanced lofting

- Considerations for motor boats

- Considerations for yachts/sailboats

- Common boat/shipbuilding terms

7. Constructing a Wooden Boat

- Construction techniques

- Designers plans

- Building moulds, jigs & strong-backs

- Wooden kit boats

- Health & safety

- Different types of wood/timber used in boat building

8. Building in GRP

- The evolution of GRP yacht building

- Materials used

- Design drawings & weights

- Kit builds & mouldings

- Building plugs & moulds

- Skills, sub contractors & tools

- Building the Hull & Deck

- Sub mouldings and bulkheads

- Health & Safety with GRP work

9. Fitting Out

- Internal Layouts

- Electrical Systems

- Water & Sanitation Systems

- Safety Equipment & Navigation Systems

- Anchoring, mooring & Deck fittings

- Painting your yacht

- Health & Safety, tools & equipment

- Skills required & sub-contracting

10. Finishing The Vessel

- Boat relocation

- Ways of lifting & launching a vessel

- The actual launch

- Stepping the mast

- Types of berth/moorings

- Modifications

Career Pathway

Career path: Many tend to come via apprenticeships in boat yards and boat builders, but this is not the only route. Some individuals undertake specific training and start on their own as contractors.

Salary: From an entry level salary at minimum wage rising to around £30,000 per annum.

Duties: All aspects of building and maintaining yachts and small craft including structure, machinery, and electrics.

DIPLOMA IN YACHT AND BOAT BUILDING

On passing the Diploma, you will receive the above icon. Please use it on your business cards, LinkedIn profile and website(s)!

You can also use these letters after your name: MTA Dip YABB

While the nature of distance learning is independent study, we recognise the importance of support. Students can contact us at any time during their course for assistance and our team of industry experts are always on hand for advice.

We have over 50 industry experts writing, developing and advising on our course material. We truly believe that allowing students to tap into their expertise and knowledge is of the utmost importance to fulfil your dream career.

If you would prefer to complete this as a classroom-based course, please contact us.

How long do the courses take to complete? What's the difference between a Diploma and a Certificate? Read through our Frequently Asked Questions below to find out the answer.

Supported By

Sign-up to receive email updates

You are using an outdated browser. Please upgrade your browser to improve your experience.

Interior design methods for yacht design and the boat building industry

By lisa c. hix.

- 7 Want to read

- 2 Currently reading

- 0 Have read

Interior design methods for yacht design and the boat building industr ...

My Reading Lists:

Use this Work

Create a new list

My book notes.

My private notes about this edition:

Check nearby libraries

- Library.link

Buy this book

This edition doesn't have a description yet. Can you add one ?

Showing 1 featured edition. View all 1 editions?

Add another edition?

Book Details

Published in, edition notes.

Includes bibliographical references (p. 248).

Classifications

The physical object, community reviews (0).

- Created October 23, 2011

- 2 revisions

Wikipedia citation

Copy and paste this code into your Wikipedia page. Need help ?

- Skip to main content

- Keyboard shortcuts for audio player

The U.S. bans most common form of asbestos, after decades of pushback from industry

Joe Hernandez

An asbestos warning sign is seen at Victoria Park in in Sydney, Australia on February 29, 2024. Jenny Evans/Getty Images hide caption

An asbestos warning sign is seen at Victoria Park in in Sydney, Australia on February 29, 2024.

The Environmental Protection Agency announced Monday that it is banning the most common form of asbestos, a cancer-causing substance that's linked to the deaths of tens of thousands of Americans every year.

The U.S. is prohibiting the use of chrysotile asbestos, joining more than 50 other countries that have already outlawed the substance. The ban comes after decades of pushback from companies that have used it in everything from consumer goods to manufacturing processes.

"The science is clear – asbestos is a known carcinogen that has severe impacts on public health," EPA administrator Michael Regan said in a statement . "This action is just the beginning as we work to protect all American families, workers, and communities from toxic chemicals."

People who inhale the tiny fibrous strands that make up asbestos can develop a slew of illnesses , including lung and ovarian cancer, asbestosis and mesothelioma. More than 40,000 deaths in the U.S. each year are connected to asbestos exposure.

Most consumer products that once contained the substance in the past no longer do, such as building materials and household appliances.

Appeals court clears the way for more lawsuits over Johnson's Baby Powder

But the EPA's ban targets certain products that still carry asbestos, including some gaskets and aftermarket automotive products. It also phases out the use of asbestos diaphragms by the chlor-alkali industry, which produces various chemicals.

Arthur Frank, a professor of environmental and occupational health at Drexel University, said the rule doesn't outlaw all forms of asbestos, and the substance still lurks in many existing buildings and products across the country.

"This is not a total ban by any means," Frank said. "It is a modest step that reduces future exposures."

Why it's taken so long for the EPA to outlaw asbestos

Federal regulators said Monday that the ban was the first rule to be finalized under the updated Toxic Substances Control Act, the national chemical safety law that was overhauled in 2016.

Previous attempts to prohibit the use of asbestos fell flat.

The EPA tried to ban asbestos outright in the late 1980s, but companies fought back. When the agency announced its 1989 prohibition on the use of asbestos, there was a carve-out for the chlorine industry.

Shots - Health News

Asbestos deaths remain a public health concern, cdc finds.

Then, two years later, a panel of federal judges deemed the rule too onerous and overturned it, scuttling for decades any additional attempts by the EPA to ban asbestos and other dangerous chemicals.

"An immediate ban on the import of chrysotile asbestos for the chlor-alkali industry is a long overdue step forward for public health," Sen. Jeff Merkley, D-Ore., said in a statement. "However, it cannot be the end of the road when it comes to phasing out other dangerous asbestos fibers, and Congress has a role to play here when it comes to providing stronger protections for our health."

What this ban will do

Though the use of asbestos in the U.S. has been on the wane, it hasn't vanished altogether.

The chlor-alkali industry uses large filters containing asbestos called diaphragms to make chemicals such as sodium hydroxide and chlorine, which can be used to disinfect drinking water and wastewater.

The EPA is immediately banning the import of chrysotile asbestos for the industry and requiring the eight chlor-alkali plants in the U.S. still using asbestos diaphragms to phase out their use.

Asbestos isn't required to produce chlorine, the agency noted, and two-thirds of the chlorine made in the U.S. is done so without the use of asbestos.

Residents near Indiana warehouse fire may have asbestos on their property, EPA says

Producers will have five years to transition from using asbestos diaphragms to ones that don't contain the substance. Those that shift from asbestos diaphragms to non-asbestos membrane technology will have five years to convert their first facility, eight years to convert their second and 12 years to convert their third.

The ban also prohibits the use of asbestos in certain products. Oilfield brake blocks, aftermarket automotive brakes and linings, and other vehicle friction products and gaskets will be barred from containing asbestos six months after the rule's effective date.

Sheet gaskets containing asbestos will also be outlawed two years after the effective date of the rule , though there will be exceptions when it's used to make titanium dioxide or for the disposal of nuclear material.

Why the U.S. put a $1 million bounty on a Russian yacht’s alleged manager

On Sept. 3, 2020, the staff of a $90 million yacht placed an order with a U.S. company for a set of luxury bathrobes that came to $2,624.35.

For roughly two years before that, according to federal prosecutors, the yacht’s management had been falsely claiming it was working for a boat named “Fanta.” But the luxury bathrobes came embroidered with a monogram that, prosecutors said, revealed the yacht’s true identity: “Tango.”

That was a problem, officials say in court papers, because Tango was owned by a Russian billionaire under U.S. sanctions, and doing business on his behalf violated federal law.

Late last month, U.S. authorities unveiled a $1 million reward for information leading to the arrest and or conviction of the man they say was running the yacht staff and orchestrated the deception with the robes — Vladislav Osipov, 52, a Swiss-based businessman from Russia. In a new indictment , federal prosecutors say Osipov misled U.S. banks and companies into doing business with the Tango yacht despite the sanctions on the Russian owner, whom the Justice Department has identified as billionaire Viktor Vekselberg .

Osipov has denied the allegations. Osipov’s attorney has said that the government has failed to demonstrate that Vekselberg owned the yacht, and that its management was therefore not a sanctions violation.

The reward offer for Osipov reflects the latest stage in the evolution of the West’s broader financial war against Russia two years into the war in Ukraine, as the United States and its allies increasingly target intermediaries accused of enabling Russian oligarchs to circumvent sanctions.

Many Russians close to President Vladimir Putin have been under sanctions dating to 2014, when Russia seized Crimea from Ukraine and sent proxy forces into that country’s eastern Donbas region. When Russia invaded Ukraine in 2022, President Biden vowed to deal a “crushing blow” with a barrage of new sanctions on financial institutions, industries, business executives and others tied to the Kremlin. But roughly two years later, Russia’s economy has proved surprisingly resilient after the nation poured tens of billions of dollars into ramping up its military industry. Moscow has also worked around the sanctions, finding new third parties to supply it with critical military and industrial hardware, as well as countries beyond Europe to buy its oil.

Now, the West is trying to increase the reach of its sanctions by digging deeper into Russian supply chains. Late last month, the Treasury Department announced more than 500 new sanctions targeting Russia , primarily on military and industrial suppliers. The Justice Department also announced charges against two U.S.-based “facilitators” of a Russian state banker who is under sanction, as well as the guilty plea of a dual national based in Atlanta who was accused of laundering $150 million through bank accounts and shell companies on behalf of Russian clients.

Prioritizing criminal charges against — and the arrests of — Western employees of Russia’s elites represents a new escalation of the U.S. financial war against Putin, experts say. One Moscow businessman, speaking on the condition of anonymity for fear of retribution, said many influential Russians are concerned about the arrest of two associates of Andrey Kostin, the head of VTB, Russia’s second-biggest state bank. These associates, Vadim Wolfson and Gannon Bond, were charged with helping Kostin evade sanctions by maintaining a $12 million property in Aspen, Colo., for Kostin’s benefit while concealing his ownership. Kostin has said that the charges of sanctions evasion against him are “unfounded” and that he has not violated any laws . Bond has pleaded not guilty; Wolfson hasn’t made an initial court appearance yet.

Wolfson, also known as Vadim Belyaev, had been a Russian billionaire until the Russian government took over his bank in 2017. Bond, 49, is a U.S. citizen from Edgewater, N.J. For all Russians living abroad and working with people in Russia, the threat of criminal charges is a much more worrying prospect than the sanctions imposed by the Treasury Department last month against hundreds of individuals and entities, the businessman said, in part because sanctions are far easier to dodge than criminal charges.

“What you have seen through today’s public announcements are our efforts at really targeting the facilitators who possess the requisite skill set, access, connections that allow the Russian war machine [and] the Russian elites to continually have access to Western services and Western goods,” David Lim, co-director of the Justice Department’s KleptoCapture task force, which is tasked with enforcing U.S. sanctions over Russia’s invasion of Ukraine, told reporters last month.

Thad McBride, an international trade partner at the law firm Bass Berry & Sims, said the crackdown on intermediaries reflected the natural evolution of the U.S. sanctions campaign in response to Russian adjustments.

“It seems to me they have gone through a comprehensive list of the oligarchs, and you can debate whether or not it’s had a meaningful impact on the Russian war effort,” McBride said. “Because they’re getting smarter about who’s who, they’re finding other people who play meaningful roles in these transactions, even though they’re not showing up in the headlines.”

The charges against Osipov related to his alleged management of the Tango yacht illustrate the mounting potential consequences for people in Europe and the United States who attempt to do business with Russians targeted by Western allies, as well as the opaque structures allegedly employed by those seeking to evade sanctions.

With a net worth estimated by Forbes in 2021 at $9 billion, Vekselberg, 66, has long drawn scrutiny from the West — and sought to safeguard his wealth. He made his initial fortune in aluminum and oil in Russia’s privatization of the 1990s and then expanded into industrial and financial assets in Europe, the United States and Africa, with Putin’s blessing. In addition to the yacht, federal prosecutors say, Vekselberg acquired $75 million worth of properties, including apartments on New York’s Park Avenue and an estate in the Long Island town of Southampton.

Vekselberg, who declined to comment for this article, has not been criminally charged by the Justice Department. In a 2019 interview with the Financial Times, he denounced the sanctions as arbitrary and harmful for international business, saying he had been targeted just because he was Russian and rich and knows Putin.

In April 2018, the Treasury Department under the Trump administration sanctioned Vekselberg and six other Russian oligarchs as part of broader financial penalties over the Kremlin’s invasion of Crimea, support for President Bashar al-Assad in Syria and interference in the 2016 U.S. presidential election. Vekselberg was also targeted for his work for the Kremlin as chairman of the Skolkovo Foundation, an attempt to create Russia’s version of the Silicon Valley — evidence that appeared to undermine the Russian businessman’s claims that he operated independently of the Kremlin.

But with Vekselberg’s payments monitored by U.S. banks, according to the federal indictment , Osipov used shell companies and intermediaries to avert the bite of sanctions. Vekselberg kept other major assets out of the reach of U.S. authorities by making use of the Treasury Department’s 50 percent ownership rule, which stipulates that it is illegal to transact with firms only if an owner under sanction controls more than 50 percent of the business.

For example, a month after Treasury imposed sanctions on Vekselberg in April 2018, his Renova Innovation Technologies sold its 48.5 percent stake in Swiss engineering giant Sulzer to Tiwel Holding AG, a group that is nevertheless still “beneficially owned” — meaning, owned in practice — by Vekselberg through Columbus Trust, a Cayman Islands trust, according to Sulzer’s corporate filing. Vekselberg’s longtime right-hand man at Renova, Alexei Moskov, replaced one of Vekselberg’s direct representatives on the board. Moskov told The Washington Post that he stepped down from all his executive positions at Renova Group in 2018 after U.S. sanctions were first imposed and from that moment ceased to be Vekselberg’s employee.

The attempts to circumvent the sanctions appear to have found some success in the U.S. legal system. Columbus Nova, a U.S.-based asset management fund controlling more than $100 million in assets in the U.S. financial and tech industry, is run by Vekselberg’s cousin, Andrew Intrater. The firm battled for more than two years to lift a freeze on Columbus Nova’s assets, imposed by Treasury’s Office of Foreign Assets Control because of the sanctions on Vekselberg, and won, reaching a settlement agreement with the Treasury Department. After renaming itself Sparrow Capital LLC, Columbus Nova successfully argued that Intrater — not Vekselberg — owns the fund. Intrater argued that the company was 100 percent owned by U.S. citizens and that no individual or entity under sanction held any interest in it. Intrater said Columbus Nova had earned fees for managing investment funds owned by Renova. He said he had repeatedly told Treasury he would not distribute any funds to Vekselberg.

Now Osipov, the alleged manager of Vekselberg’s $90 million yacht, is attempting a similar argument as U.S. authorities seek his arrest on charges of bank fraud, money laundering, conspiracy to defraud the United States, and violations of sanctions law.

The federal indictment states that the Tango was owned by a shell corporation registered in the British Virgin Islands that was in turn owned by several other companies. The Virgin Islands shell company, authorities say, was controlled by Osipov, who also served in senior roles for multiple companies controlled by Vekselberg. U.S. officials also say Vekselberg ultimately controlled the other companies that owned the Virgin Islands shell company.

According to the indictment, a Tango official instructed a boat management company in Palma de Mallorca, Spain, to use a false name for the yacht — “Fanta” — to disguise its true identity from U.S. financial institutions and firms, which try to avoid doing business with an entity or person under sanction.

Working at Osipov’s direction, according to the indictment, employees for Tango bought more than $8,000 worth of goods for the yacht that were unwittingly but illegally processed by U.S. firms and U.S. financial institutions, including navigation software, leather basket magazine holders provided by a bespoke silversmith, and web and computing services. The management company running Tango, run by Osipov, also paid invoices worth more than $180,000 to a U.S. internet service provider, federal prosecutors say.

The Tango was seized by the FBI and Spanish authorities in the Mediterranean not long after Russia invaded Ukraine in 2022, and Osipov was first indicted last year. The owner of the Spanish yacht management company hired by Osipov, Richard Masters, 52, of Britain, was criminally charged last year by federal prosecutors with conspiracy to defraud the United States and violating federal sanctions law. A request for comment sent to Masters’ firm was not returned.

But in recent court documents, Osipov’s attorney argues that the yacht was not more than 50 percent owned by Vekselberg, and that the government hasn’t demonstrated it was. Barry J. Pollack, an attorney at Harris, St. Laurent and Wechsler, also says the government never warned Osipov of its novel and “unconstitutional” application of federal sanctions law.

“The government points to no precedent that supports its extraordinary interpretation and cites no authority that allows the traditional rules of statutory construction to be turned on their head,” Pollack wrote in a defense filing. The filing adds: “[Osipov] is not a fugitive because he did not engage in any of the allegedly criminal conduct while in the United States, has never resided in the United States, did not flee from the United States, and has not concealed himself.”

Still, the State Department’s Transnational Organized Crime Rewards Program has said it will provide up to $1 million for information leading to Osipov’s arrest, warning that he may visit Herrliberg, Switzerland; Majorca, Spain; or Moscow.

The case demonstrates the extent of the U.S. commitment to tighten the screws on those seen as aiding Russian elites, even if they themselves are not closely tied to the Kremlin.

“When DOJ levels legal action against an individual or entity, they have quite a bit of evidence, especially because the threshold to press charges for money-laundering and sanctions evasion is so high,” said Kim Donovan, director of the Economic Statecraft Initiative within the Atlantic Council’s GeoEconomics Center. “We’ve had quite a bit of experience targeting Russia directly, and what you’re starting to see is the U.S. go after the facilitators enabling sanctions evasion. That’s where the U.S. is focusing its efforts right now.”

- Bahasa Indonesia

- Slovenščina

- Science & Tech

- Russian Kitchen

Cruising the Moskva River: A short guide to boat trips in Russia’s capital

There’s hardly a better way to absorb Moscow’s atmosphere than on a ship sailing up and down the Moskva River. While complicated ticketing, loud music and chilling winds might dampen the anticipated fun, this checklist will help you to enjoy the scenic views and not fall into common tourist traps.

How to find the right boat?

There are plenty of boats and selecting the right one might be challenging. The size of the boat should be your main criteria.

Plenty of small boats cruise the Moskva River, and the most vivid one is this yellow Lay’s-branded boat. Everyone who has ever visited Moscow probably has seen it.

This option might leave a passenger disembarking partially deaf as the merciless Russian pop music blasts onboard. A free spirit, however, will find partying on such a vessel to be an unforgettable and authentic experience that’s almost a metaphor for life in modern Russia: too loud, and sometimes too welcoming. Tickets start at $13 (800 rubles) per person.