- Facebook Page

- Twitter Page

- Instagram Page

- Youtube Page

What is it you're looking for?

Everything you need to know about Yacht Varnish

Applying Ronseal Trade Yacht Varnish to wooden garden features is a fantastic way of prolonging them. It can be used on all smooth planed exterior wood and offers incredibly tough protection against damage and decay – whilst still highlighting the timber’s natural colour thanks to its clear formula.

The appetite for incorporating natural materials throughout the home and garden is on the up – and as such, we have seen a rise in the number of people interested in garden features such as wooden pergolas, hardwood furniture and rustic wooden details.

When speaking to customers about their ideal garden designs, don’t shy away from incorporating these wooden elements for fear of them warping or decaying in the unpredictable British weather. With the correct preparation, timber can offer the durable and long-lasting finish customers are after.

What is Yacht Varnish?

Yacht Varnish is an incredibly durable solvent-based varnish that was originally used to on boats to protect the wood and prevent it from decaying over time. Nowadays, this type of product is more commonly used for exterior household projects, when you are looking to give timber a high-gloss finish that lasts.

Once applied, Ronseal Trade Yacht Varnish is tough and will protect timber against everyday knocks and scratches as well as harsh weather conditions to prevent cracking, peeling and blistering. What’s more, it is formulated to protect the wood from the damaging effects of the sun and prevent it from discolouring, fading or greying over time. This makes it ideal for features such as wooden pergolas, doors and window frames that are exposed to the elements all year round and ensures that they will last for years to come.

Why choose Ronseal Trade?

Cleverly, Ronseal Trade Yacht Varnish has been formulated to offer the excellent weatherproofing and durability you would expect from a solvent-based varnish but without the long re-coat times. Impressively, it offers around half the re-coat time of a typical solvent-based varnish; it is rainproof in just four hours and it can be re-coated in as little as eight hours. This means that time on site and disruption to the customer can be reduced.

To find out more about Ronseal Trade Yacht Varnish click here .

Share article

How to Use Yacht Varnish? (A Step-by-Step Guide)

Are you looking for a way to give your boat a polished, professional finish? Yacht varnish provides a layer of protection and a beautiful shine that wont fade over time.

In this step-by-step guide, well explain what yacht varnish is, the benefits of using it, and how you can apply it to your boat.

Well also discuss preparation, application, drying, and sanding between coats, so you can be sure your boat is looking its best.

So, if youre ready to learn how to use yacht varnish, lets get started!.

Table of Contents

Short Answer

Yacht varnish is a protective coating used to seal and protect wood surfaces on boats.

To apply yacht varnish, start by sanding the wood surface with a fine-grit sandpaper.

Then, apply a thin coat of the varnish with a brush, working in long, even strokes.

Allow the varnish to dry for 24 hours before applying a second coat.

Finally, sand the surface with very fine sandpaper before buffing it with a soft cloth.

What is Yacht Varnish?

Yacht varnish is a specialized wood finish designed to protect outdoor wood surfaces from moisture and UV damage.

It typically consists of a blend of resins, oils, and solvents that provide a tough, yet flexible coating, which is ideal for protecting boat decks, outdoor furniture, and other wood surfaces that are exposed to the elements.

Yacht varnish also provides a glossy, attractive finish that enhances the beauty of the wood.

Unlike paint, yacht varnish does not completely cover the wood, allowing the natural grain of the wood to show through.

It is also relatively easy to apply and maintain, making it a popular choice for marine and outdoor wood surfaces.

Benefits of Yacht Varnish

When it comes to protecting outdoor wood surfaces, yacht varnish is an excellent choice.

Not only does it protect the wood from moisture and UV damage, but it also adds a beautiful shine and luster to the wood.

Yacht varnish is a long-lasting coating that can provide years of protection under the right conditions.

It is also easy to apply and can be used on a variety of wood surfaces, including boats, decks, and other outdoor wood surfaces.

When applied correctly, yacht varnish offers many benefits.

It forms a protective barrier against moisture and UV damage, preventing fading, cracking, warping, and other damage that can occur with prolonged exposure to the elements.

The coating also helps keep the wood from rotting, which can be an issue if the wood isn’t properly sealed.

Finally, the varnish adds a beautiful shine and luster to the wood, making it look like new.

Yacht varnish is also easy to apply and can be used on a variety of wood surfaces.

It is a great choice for any outdoor wood surface, including boats, decks, furniture, and more.

It is also relatively inexpensive and can be found at most home improvement stores.

With the right application, yacht varnish can provide years of protection and a beautiful finish to any outdoor wood surface.

Preparing the Wood Surface

Before applying yacht varnish, it is important to properly prepare the wood surface.

The surface should be thoroughly cleaned and dried, and any old varnish should be removed.

Sanding the wood will also help to ensure a smooth, even finish.

It is important to use the correct type of sandpaper for the project.

For instance, a medium-grit sandpaper is suitable for most wood surfaces, while a finer grit may be necessary for surfaces that require a more delicate finish.

Once the surface is prepared, it should be wiped down with a damp cloth to remove any dust or debris.

This will help ensure a successful application of yacht varnish.

Applying the Varnish

When it comes to applying yacht varnish, its important to understand the steps involved in the process.

First, the wood surface should be clean, dry, and sanded.

This ensures that the varnish will adhere properly and will provide maximum protection.

Next, apply a thin coat of varnish with a natural-bristle brush.

This helps to ensure even coverage and minimal brush strokes.

Allow the varnish to dry before applying a second coat.

Its important to allow the varnish to dry completely before applying any additional coats.

Sand lightly between coats to help ensure an even surface.

Additional coats should be applied as needed, but always be sure to allow the varnish to dry completely before exposing the surface to the elements.

With proper application, yacht varnish will protect your outdoor wood surfaces for years to come.

Allowing the Varnish to Dry

When it comes to yacht varnish, it is important to allow the varnish to dry completely before exposing the surface to the elements.

This will ensure that the varnish is properly bonded to the wood and will provide optimal protection from moisture and UV damage.

It is best to allow the varnish to dry for at least 24 hours before applying a second coat.

The drying time will also depend on the temperature and humidity of your environment, so it is important to allow for extra time if these conditions are not ideal.

Once the varnish is dry, it is recommended to lightly sand the surface before applying a second coat.

This will help to ensure that the varnish bonds properly and that the finish is even and smooth.

If additional coats are needed, the process should be repeated.

It is important to allow the varnish to dry completely between each coat, as this will ensure that the varnish fully bonds with the wood.

For best results, allow the varnish to dry for at least 48 hours before exposing the surface to the elements.

By allowing the yacht varnish to dry completely, you can be sure that the wood is properly protected and that the finish will last for years to come.

Sanding between Coats

Sanding between coats is an important step when applying yacht varnish.

After each coat of varnish is applied and has dried, the surface should be lightly sanded to remove any imperfections.

Sanding helps create a smooth, even finish and provides more effective protection against moisture and UV damage.

It also helps ensure that the next coat of varnish adheres properly to the surface.

When sanding between coats, use a fine-grit sandpaper (preferably around 320-400 grit) and sand in the direction of the wood grain.

This helps prevent scratches and other damage to the wood.

Be sure to only sand lightly, as sanding too aggressively can damage the wood and reduce the effectiveness of the varnish.

After sanding, use a clean cloth or brush to remove any dust or debris from the surface.

This will help ensure that the varnish adheres properly and provides the best possible protection.

Once the surface is clean, apply the next coat of varnish as normal.

With proper sanding between coats, yacht varnish will provide effective protection and lasting results.

Applying Additional Coats

Once you have applied the first coat of yacht varnish, it is important to apply additional coats for the best protection.

Depending on the specific product you are using, you may need to apply anywhere from two to seven coats.

It is important to allow the first coat to dry completely before applying any additional coats.

When applying additional coats, it is recommended to lightly sand the surface between each application.

This will help ensure a smooth, even finish and allow the varnish to adhere better.

After sanding, be sure to remove any dust or debris before applying the next coat.

When applying multiple coats of yacht varnish, it is important to use the same type of brush and same technique each time.

This will help ensure a consistent finish.

For example, if you used a natural-bristle brush when applying the first coat, it is recommended to use the same type of brush for subsequent coats.

Additionally, use long, even strokes when applying the varnish.

It is important to note that you should avoid applying too many coats of yacht varnish.

Too many coats can cause the varnish to become too thick and may make the surface appear uneven.

Generally, three to four coats should be more than enough.

Once you have finished applying the desired number of coats, allow the varnish to dry completely before exposing the surface to the elements.

With proper application and care, yacht varnish will help protect your outdoor wood surfaces for years to come.

Final Thoughts

Yacht varnish is a great way to protect your outdoor wood surfaces from moisture and UV damage.

Its important to apply yacht varnish correctly in order to get the best results.

Start by preparing the wood surface, then apply a thin coat with a natural-bristle brush.

Allow the varnish to dry before sanding and applying additional coats as needed.

With proper application, you can enjoy your outdoor wood surfaces for years to come.

Now that you know how to use yacht varnish, why not give it a try on your next project?.

James Frami

At the age of 15, he and four other friends from his neighborhood constructed their first boat. He has been sailing for almost 30 years and has a wealth of knowledge that he wants to share with others.

Recent Posts

When Was Banana Boat Song Released? (HISTORICAL INSIGHTS)

The "Banana Boat Song" was released in 1956 by Harry Belafonte. This calypso-style song, also known as "Day-O," became a huge hit and remains popular to this day for its catchy tune and upbeat...

How to Make Banana Boat Smoothie King? (DELICIOUS RECIPE REVEALED)

To make a Banana Boat Smoothie King smoothie at home, start by gathering the ingredients: a ripe banana, peanut butter, chocolate protein powder, almond milk, and ice. Blend the banana, a scoop of...

Practical Boat Owner

- Digital edition

Painting and varnishing a boat: how to get the perfect finish

- Polly Robinson

- April 22, 2024

Kit boat builder Polly Robinson shares her tips for painting and varnishing a plywood-epoxy boat

Spending time painting and varnishing delivers excellent results. Credit: Polly Robinson Credit: Polly Robinson

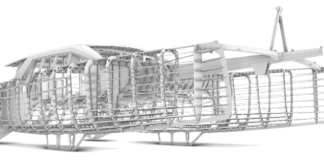

Plywood-epoxy construction is a modern boatbuilding method that allows you to build a boat quicker than traditionally built boats.

But epoxy requires UV protection to stop it from breaking down and yellowing over time, so applying a finish is both practical and cosmetic.

Preparing for painting and/or varnishing a boat

The most important part of the finishing of your plywood-epoxy boat is the surface preparation before you add paint or varnish .

Spending extra time and effort at this stage will mean you get a better result.

The finish is what people will notice, so it’s worth putting the time in. The preparation for paint and varnish is the same.

The boat before the painting and varnishing. Credit: Polly Robinson

After you have completed laying the fibreglass and applied the fill coat which is used to fill the weave of the glass, you’ll need to fair the hull.

First sand the boat inside and out to get rid of any high point or epoxy drips from the glassing stage.

If you have been particularly relaxed with cleaning up spills you may need to start with a 60-grit paper to get any big drips off but usually, you can start with 80-grit.

You need to take care to not go through the weave of the glass, as this is what is giving your plywood boat its strength and protecting the plywood from water ingress .

Getting started on painting and varnishing a boat

Watertite applied to the lapstrakes on any low spots. Credit: Polly Robinson

- Starting with 60- or 80-grit paper, remove any high spots from the boat. I usually start with any obvious drips or runs and then work bow to stern and cover the whole boat using a random orbit sander. Take your time and keep moving, you don’t want to sand too much and add low points using the sander, as these will need filling in later.

- Once you’ve removed the high spots you need to then work from bow to stern using 120-grit to remove any scratches made by the 80-grit. I repeat the 120-grit two to three times to ensure the whole boat is smooth. Run your hands over the boat as this is an easier way to find any high spots you’ve missed – your eyes can be deceived by the light bouncing off the epoxy coating.

- Check the boat for any low points; getting down to eye level and looking along the boat is a good way of doing this. You need good lighting so if the boat is small enough or on a trailer, it’s worth taking it outside.

- If you find any low points you can use some epoxy thickened with microballoons to skim over and fill the hollows. You’ll then need to re-sand these, but it’s worth doing it at this stage rather than earlier as you need the boat smooth to see the dips. If you intend to paint the boat, I have known people use a marine body filler instead of epoxy here, such as Watertite by International. You can apply this to any dips and then sand back to achieve an even surface.

- Wait for the filler to cure properly – and do not sand partially-cured epoxy.

- Finally sand the entire boat with 240-grit – the epoxy should turn a milky opaque colour at this stage. The aim is to buff out any scratches but also remove the ‘shine’ of the epoxy. This keys the surface which is required for the paint or varnish to bond. Don’t be concerned by the milky appearance as the varnish will turn the epoxy back to its shiny look.

- Once happy with the finish, lightly clean the boat with meths and leave it to fully dry. Ensure the workshop is as free of dust as possible – you don’t want to be kicking it up when painting and varnishing. Note: you should always wear a dust mask and eye protection when sanding. When sanding epoxy, ensure your skin is covered and the workshop or garage is well ventilated. Most sanders have dust collection available, and this should be used; you’ll want to keep the dust to a minimum when painting later.

Paint or varnish?

If you have chosen to paint either inside or outside or a combination of the two you have probably put a lot of thought into which colour.

Light paints make the boat look bigger.

If you have a clinker-style boat then light colours allow a shadow to form under the planks which exaggerates the clinker and looks fantastic.

A combination of paint and varnish also looks great – and shows that your boat is wooden too.

Varnishing a boat: The boat after the first coat of varnish. A minimum of four coats will be needed. Credit: Polly Robinson

A lot of smaller boats have the top strake varnished, along with the transom , which is a great combination.

It’s also worth thinking about how you will use your boat.

Paint is more hardwearing than varnish and will generally require less maintenance.

If you have any flaws in the boat or marks on the plywood, paint will hide them whereas varnish will probably make them more obvious.

If the build has been carefully done and you have a great figuring pattern on the plywood, a fully varnished ‘bright’ boat is a real head-turner.

Epoxy does breakdown over time when exposed to sunlight and can yellow.

So whether you decide to go with paint or varnish , just make sure the entire boat has one or the other protecting it.

Painting the boat

For the boat I’m currently working on we decided to paint the hull, leaving the top strake and transom varnished. Inside the boat will be varnished too.

You can use an anti-slip paint on the bottom panels, which provides more traction underfoot.

This is a good idea if you’ll be stepping in and out of the boat with wet feet, and should reduce the risk of an unexpected swim!

You’ll want to use an undercoat and topcoat to get an even finish. I use International One Up which is a primer and undercoat in one and gives a good coverage from the first coat.

It’s easy to work with and applies well.

I use this with International Toplac Plus which is a high gloss enamel finish. It comes in a good range of colours and gives a beautiful finish.

Side view with the first coat of topcoat. Note the masking tape on the topstrake to ensure a clean line. Credit: Polly Robinson

If you’re planning to keep your boat on the water year-round you will need a suitable paint.

It’s always worth giving the paint manufacturer a call and chatting through your options.

It’s also worth mentioning that your undercoat and topcoat need to be compatible. Paints are either single-pack or two-pack.

As a rule, two-pack paints can’t be applied over single-pack paints.

Continues below…

How to build a boat: Essential guide to building your first kit boat

You don’t have to be a boatbuilder to learn how to build a boat, argue Roger Nadin and Polly Robinson.…

8 quick tips for varnishing

Some tips and tricks to get the best finish possible when varnishing your boat's woodwork

Surface preparation for polishing or varnishing a boat

Mirka’s Andy Mierau shares trade tips on how to prepare surfaces for polishing or varnishing

Best boat varnish: 7 top options for gleaming woodwork

Few things are as quintessential to the archetypal sailboat as gleaming, iridescent woodwork that is indicative of a recent coat…

Two-pack paints are stronger, and the solvents will soften the undercoat. Single-pack can usually be applied over two-pack, but I would recommend sticking to the same system.

Roller size is also worth considering.

The boat I was painting was only 7ft 6in/2.3m LOA with a 4ft/1.2m beam and 6ft/1.8m panels on each side, so they were thin.

I used a 4in roller as any bigger would have made it tricky to get good coverage.

If you’re painting a larger boat or one with larger panels, then a larger roller will give better coverage as you’ll not need so many passes to cover a panel.

Get cracking

- Now we’ve decided on a finish, the first step is to mask off the parts that will be varnished. Care should be taken to get the lines even and a ‘true line’. Where the paint and varnish meet will be where the eye is drawn to, so this needs to be correct and even on both sides.

- Paint is temperature sensitive so check the manufacturer’s guidelines. I was finishing the boat in an unheated garage so used a small plug-in heater to achieve the required temperature.

- The rest of the varnish area can then be masked off with newspaper to stop any splashes from getting on the boat. Cover the gunwales too when painting the boat upside down.

- Check the instructions on your paint. The system I am using – International One Up – requires three coats and thinners. Decant roughly the amount of paint needed for the first coat into a container and add the thinners. Mix well.

- Use a foam roller to apply the paint . Do not overload the roller as this will cause the paint to run. Work along the boat, ensuring an even coat. Once you have rolled the paint on, follow with the brush to remove any bubbles left by the roller (known as ‘tipping off’). Slow and steady is key and keep the coat thin.

- Once the undercoat is on, check the boat for any missed spots. Leave to dry according to the manufacturer’s instructions on the tin –there is often a recoating time.

- Once dry, lightly sand the paint with 240-grit paper and apply a second coat in the same way. You should start to get a uniform colour across the entire area painted. The paint I used was pigmented enough that I only needed two coats, but some brands may require a third. Ensure you lightly sand between coats.

- Once the undercoat is fully cured (you can find the full cure times on the manufacturer’s website or the paint tin) you can prepare for the topcoat. Lightly sand the painted area again with 400-grit.

- Decant the topcoat into a fresh container and repeat the process. You may not need to use thinners this time – check the manufacturer’s instructions.

- You’ll need to do multiple coats; sand with 300- to 400-grit paper in between coats. I used International Toplac Plus which was beautifully pigmented, so I only needed three coats.

Varnishing a boat

There are many varnishes on the market. Some have a slight colour, so it’s worth checking if you’d like yours clear to show the colour of the wood as is, or tinted if you would like it slightly darker.

I have sapele gunwales on my boat, which is a dark coloured wood, so I opted for a slightly tinted varnish to complement these.

I used International Original, which I’d highly recommend. It’s a beautiful honey colour and applies well.

Varnishing a boat: Dinghy looks smart with a fresh coat of epoxy – but will need painting or varnishing to protect the epoxy from UV sunlight. Credit: Polly Robinson

Keep the varnish in a warm area before using it, so it flows well and is easier to work with.

Thin layers of varnish that you build up are key to a good finish. Varnish will easily run if you try and put too much on at once.

It’s worth investing in a good varnishing brush. You should be able to find one in your local hardware shop but ensure it is a non-bristle dropping brush.

Varnishing the gunwale. Always use a good quality brush for a bristle-free finish. Credit: Polly Robinson

It’s infuriating after you’ve applied a beautiful varnish to find you’ve left brush bristles all over the boat.

The epoxy should have been sanded up to 240-grit, cleaned with meths and allowed to dry as before.

- Mask off any areas where the varnish meets the paint. This stops the varnish from running onto the paint, especially important if using a tinted varnish and a light coloured paint.

- Some varnishes may need thinners, check your instructions. The varnish I was using did not require thinners unless being used on bare wood.

- Decant some varnish into a clean plastic container. If you were using thinners you would add them at this stage.

- Dip the tip of the varnish brush into the decanted varnish, and wipe off any excess using the rim of the container. You want a very light amount on the brush so don’t overload it. Thin layers are key to a good finish.

- Brush the varnish slowly along the panel. If the brush runs dry then re-dip into the varnish, but be very careful to not overload the brush. Then come back against the direction you have applied the varnish.

- Start the next pass of varnish, slightly overlapping that you’ve just applied, which is called the wet edge.

- I like to work along the boat one panel at a time. Because we are varnishing a plywood-epoxy boat we do not need to worry about grain patterns, so I find working one panel at a time to be the most methodical.

- If you miss a small spot don’t be tempted to go back over it at this stage. Finish the first coat and then catch it on the second coat.

- Once the varnish is dry, lightly sand with 300- to 400-grit paper and then repeat the steps above, working slowly and methodically. The time between coats will vary with brands, so do check the tin.

- You will need to apply a minimum of four coats. The more the better, up to around 10 coats.

Maintaining paint and varnish

Paint and varnish do need maintenance to keep them looking their best.

Surface scratches are unavoidable, but you can add brass rubbing strips to the bottom of the hull if you’ll be launching somewhere particularly rocky.

At the end of the season, giving the boat a light sand will get any surface scratches out and a fresh coat will keep the boat looking smart.

Painting and varnishing a boat: step by step

Credit: Polly Robinson

1. International Watertite applied to any ‘low’ areas after fairing the hull. Note masking tape on the topstrake ready to protect it from the undercoat.

2. The sanded boat ready for painting. You can see how the epoxy appeared ‘milky’ after sanding.

3. Here, the first coat of undercoat has been applied. You can see it’s patchy in places and requires a second coat.

4. Applying the second coat of undercoat – it appears patchy when wet but dries to an opaque finish.

5. Applying the topcoat, one panel at a time using a roller, followed immediately by a ‘tipping off’ brush.

6. Overhead view showing the boat with the first application of topcoat.

7. Final topcoat applied to the hull. Once this is dry the boat will be ready for applying varnish to the upper lapstrake.

8. You can see the left hand side of the bowseat has had fresh varnish applied, and the line where we have varnished up to. The next brushful will be applied overlapping this.

9. Getting started on varnishing the topstrake. A head torch is a good way to see where you’ve varnished so far and to ensure you’re not missing any spots.

10. Work on one panel at a time to ensure a thin, even coat of varnish. Be sure to take up just a small amount of varnish on the brush each time to avoid runs.

11. Applying a first coat of varnish to the gunwales. See how the varnish turns the ‘milky’ sanded epoxy to a satisfying bright, shiny finish.

12. With the final of many coats of varnish applied to the dinghy inside and out it’s job done!

Enjoy reading Painting and varnishing a boat: how to get the perfect finish?

A subscription to Practical Boat Owner magazine costs around 40% less than the cover price .

Print and digital editions are available through Magazines Direct – where you can also find the latest deals .

PBO is packed with information to help you get the most from boat ownership – whether sail or power.

- Take your DIY skills to the next level with trusted advice on boat maintenance and repairs

- Impartial in-depth gear reviews

- Practical cruising tips for making the most of your time afloat

Follow us on Facebook , Instagram, TikTok and Twitter

- New Sailboats

- Sailboats 21-30ft

- Sailboats 31-35ft

- Sailboats 36-40ft

- Sailboats Over 40ft

- Sailboats Under 21feet

- used_sailboats

- Apps and Computer Programs

- Communications

- Fishfinders

- Handheld Electronics

- Plotters MFDS Rradar

- Wind, Speed & Depth Instruments

- Anchoring Mooring

- Running Rigging

- Sails Canvas

- Standing Rigging

- Diesel Engines

- Off Grid Energy

- Cleaning Waxing

- DIY Projects

- Repair, Tools & Materials

- Spare Parts

- Tools & Gadgets

- Cabin Comfort

- Ventilation

- Footwear Apparel

- Foul Weather Gear

- Mailport & PS Advisor

- Inside Practical Sailor Blog

- Activate My Web Access

- Reset Password

- Customer Service

- Free Newsletter

Aluminum Cruisers: The Basics for First-Time Buyers

Marshall Sanderling 18: Used Boat Review

Affordable Cruising Sailboats, Continued

Maine Cat 41 Used Boat Review

Tillerpilot Tips and Safety Cautions

Best Crimpers and Strippers for Fixing Marine Electrical Connectors

Thinking Through a Solar Power Installation

How Does the Gulf Stream Influence our Weather?

Need a New Headsail Furler? Here’s What’s Involved

Master the Sailing Basics: Never Stop Learning the Little Things

How to Mount Your Camera on Deck: Record Your Adventures with…

Un-Stepping the Mast for America’s Great Loop

Ensuring Safe Shorepower

Sinking? Check Your Stuffing Box

The Rain Catcher’s Guide

How to Change Your Engine Mounts

Vinyl Boat Lettering DIY Application and Repair

Those Extras you Don’t Need But Love to Have

Three-Model BBQ Test

Alcohol Stoves— Swan Song or Rebirth?

UV Clothing: Is It Worth the Hype?

Preparing Yourself for Solo Sailing

How to Select Crew for a Passage or Delivery

Preparing A Boat to Sail Solo

Dear Readers

Chafe Protection for Dock Lines

Waxing and Polishing Your Boat

Reducing Engine Room Noise

Tricks and Tips to Forming Do-it-yourself Rigging Terminals

- Boat Maintenance

The Best Marine Varnish: Exterior Wood Finish Tests

Two-part varnishes leading in durability as long-term test reaches 24-month mark..

Like spotting land after a long passage, were glad to say that the end of our long-term exterior wood finishes test is finally on the horizon. Time, weather, and Southwest Floridas unrelenting sunshine have clearly taken their toll on the test panels over the last 24 months, and as the evaluation moves into its third year, only 19 of the original 54 test products will continue on in our survival-of-the fittest finish matchup. Given that most wood coatings are rarely expected to last longer than two years in the marine environment-particularly in super-sunny locales-its no surprise that we’ve seen more significant changes in the coatings in the last six months than we had in previous checkups.

Our search for the ideal wood finish-relatively easy to apply, easy to maintain, lasts multiple seasons, and is affordable-began in 2007 when we took a look at the different types of exterior wood finishes on the market, their pros and cons, and how easy they were to apply ( one-part varnishes , August 2007; varnish alternatives , October 2007; two-part varnishes , December 2007; teak oils and stains , April 2008). Launched in 2008, the long-term panel test aimed to determine which type of coating offers the best and longest protection and which products stand out among their peers.

We hope the comparison enables readers to decide which finish best matches their own taste, potential labor investment, and wood protection needs.

We’ve rated the test products every six months and reported on the coatings durability in the May 2009 issue ( six-month checkup ), December 2009 issue ( 12 months ), and January 2011 ( 18 months ) issues. Here, we offer the two-year report on the survivors.

How We’re Testing the Marine Varnishes

Testers applied dozens of exterior wood finishes (22 one-part varnishes, six two-part varnishes, 18 synthetics and satins/varnish alternatives, and eight teak oils and sealers) to small panels of bare solid teak. Each was assigned a number for blind judging and was applied per manufacturers instructions. If makers gave a range for the number of coats to apply, testers went with the minimum.

Initial testing rated each products ease of application and original gloss and reflective qualities. In the summer of 2008, the test panels were mounted on a wooden rack (aka: The Rack), which was set up in an unobstructed area on the roof of the PS workshop in Sarasota, Fla., to ensure that all panels received the same amount of weather exposure. The top part of each panel was covered to create a control area that testers used for comparison over time. Every six months, we disassembled The Rack and rated the panels on how well their coating integrity, gloss, and color had fared over time with constant exposure to the elements.

The test was designed as an endurance test, a fight to the finish, so we have not done any maintenance coats or touch-ups to the test panels. These products can be expected to have much longer lifespans if they are regularly maintained.

How We’re Rating the Marine Varnishes

Testers rate each panel on three long-term performance criteria: coating integrity, gloss retention, and color retention. Excellent and Good coating integrity ratings mean that no maintenance is needed; a Fair indicates that its time for a maintenance coat; Poor means the fat lady has sung, and the coating would need to be removed and re-applied. Excellent ratings are given only to those with an uncompromised coating. This time, panels with Poor and Fair- coating integrity were pulled from the test.

Color and gloss retention ratings are relative to the panels original finish. Initial gloss and ease of application are relative to the field within each coating category; these were assigned immediately after the panels were coated.

It was tougher to pick Recommended coatings at the two-year mark, as most wood finishes aren’t intended to go that long without maintenance. One-part varnishes that earned PSs recommendation this go-round were rated Fair for coating integrity (none rated better than Fair ) and had no Poor ratings. Recommended two-part systems rated Good or better for coating integrity with no Poor ratings. No varnish alternatives or teak oils/sealers were recommended at two years.

VALUE GUIDE: Varnish Alternatives

| PRODUCT | PRICE | AFTER 2 YEARS COAT INTEGRITY | GLOSS RETENTION | COLOR RETENTION | AFTER 1 YEAR COAT INTEGRITY | GLOSS RETENTION | COLOR RETENTION | INITIAL RATINGS EASE OF APPLICATION | GLOSS/ FINISH NOTES |

|---|---|---|---|---|---|---|---|---|---|

| Epifanes Rapidclear | $26/ quart | Poor | Poor | Fair | Fair | Good | Fair | Excellent | Clear/satin |

| Interlux Sikkens Cetol Marine (alone) | $25/ quart | Fair | N/A | Fair+ | Excellent | N/A | Good | Excellent | Opaque amber/ matte |

| Interlux Sikkens Cetol with Marine Gloss | $25/ quart (Gloss $28) | Fair+ | Poor | Good | Excellent | Excellent | Good | Good | Opaque amber; clear overcoat/ Satin |

| Interlux Sikkens Cetol Marine Light (alone) | $25/ quart | Fair | N/A | Fair | Good+ | N/A | Fair | Excellent | Opaque light amber/ matte |

| Interlux Sikkens Cetol Marine Light with Marine Gloss | $25/ quart (Gloss: $28) | Fair+ | Poor | Good | Excellent | Excellent | Good | Good | Opaque amber; clear overcoat/ satin |

| Interlux Sikkens Cetol Natural Teak with Marine Gloss | $26/ quart (Gloss: $28) | Fair- | Fair | Poor | Good | Good | Fair | Good | Golden-translucent, clear overcoat/ satin |

| Le Tonkinois Bio Impression with Vernis | N/A | Fair | Poor | Fair | Good | Fair | Fair | Good | Warm, dark amber/ high gloss |

| West Marine WoodPro Plus Semi-Gloss | $30/ quart | Poor | Poor | Fair | Fair | Fair | Fair | Good | Clear/ satin |

| WoodPlus Marine Natural | $21/ quart | Fair- | Poor | Poor | Good | Good | Fair | Excellent | Reddish brown/ low gloss |

| Ace Spar Varnish Gloss 16373 | $13/ quart | Fair- | Fair- | Good | Good | Good | Good | Excellent | Good |

| Coelan (with primer) | $145/ kit | Fair- | Fair | Fair- | Excellent | Excellent | Good | Good | Excellent |

| Deft Defthane Poly Satin | $13/ quart | Fair- | Poor | Fair- | Excellent | Good | Good | Excellent | Fair |

| Detco Crystal | $41/ quart | Good- | Fair | Fair- | Good | Good | Good | Fair | Good |

| Epifanes Clear High Gloss | $27/ quart | Fair- | Fair- | Good | Excellent | Excellent | Good | Good | Excellent |

| Epifanes Wood Finish Gloss | $36/ quart | Fair | Poor | Fair | Excellent | Excellent | Good | Good | Excellent |

| HMG K Type Varnish | $30/ liter | Poor | Poor | Poor | Excellent | Good | Fair | Good | Excellent |

| Interlux Goldspar Cllear | N/A | Fair+ | Fair- | Fair+ | Good | Excellent | Good | Good | Excellent |

| Interlux Jet Speed | N/A | Fair | Poor | Fair | Fair | Fair | Good | Excellent | Excellent |

| Interlux Schooner | $23/ quart | Fair+ | Fair- | Poor | Good+ | Good | Fair | Good | Good |

| Le Tonkinois No. 1 | $35/ liter | Fair- | Poor | Fair | Fair | Fair | Good | Excellent | Excellent |

| Le Tonkinois Vernis | $33/ liter | Fair+ | Fair- | Fair+ | Excellent | Fair | Good | Excellent | Excellent |

| Minwax In/Outdoor Helmsman Spar Urethane | $17/ quart | Fair | Fair | Poor | Good | Good | Fair | Excellent | Excellent |

| Pettit Bak V-Spar 2053 | N/A | Fair- | Poor | Poor | Fair | Poor | Fair | Excellent | Excellent |

| Pettit Z-Spar 2015 Flagship | $30/ quart | Fair | Fair | Fair | Good | Excellent | Good | Excellent | Excellent |

| Pettit Z-spar Captain's Ultra Clear 2067 | $30/Quart | Fair+ | Fair | Fair | Excellent | Good | Fair | Excellent | Excellent |

| Pettit Z-Spar Captain’s 1015 Traditional Amber | $28/ quart | Fair- | Poor | Fair | Excellent | Good+ | Good | Good | Good |

| Pettit Z-Spar Captain’s EZ Care 1016 (Woolsey) | N/A | Fair | Fair- | Good | Good | Good | Good | Excellent | Good |

| West Marine 5-Star Premium | $32/ quart | Fair- | Poor | Fair | Excellent | Good | Fair | Good | Excellent |

| TWO-PART SYSTEMS | |||||||||

| Bristol Finish, Traditional Amber | $70/ kit (1 quart) | Poor | Fair | Good | Fair | Excellent | Good | Excellent | Excellent |

| HMG Acrythane XSC | $45/ liter | Fair | Good | Fair+ | Good+ | Excellent | Good | Good | Good |

| Honey Teak with overcoat | $2/ sq. ft. | Fair- | Good | Fair | Fair | Good | Good | Excellent | Excellent |

| Interlux Perfection | $60/ kit (1 quart) | Excellent | Excellent | Good | Excellent | Excellent | Good | Good | Excellent |

| Nautiking NautiThane | $120/ kit (1 quart) | Good | Good- | Good | Excellent | Excellent | Good | Excellent | Good |

| Smith Five-Year Clear | N/A | Good | Good | Fair | Good+ | Excellent | Good | Good | Excellent |

What We Found

What a difference a season makes! With the exception of a few two-part products, the test coatings had lost their sparkle at the two-year mark. Ratings slipped across the board. The UV abuse had obviously taken its toll, sucking the life out of most of the coatings, particularly the clear finishes.

Those clinging to life with Fair coating integrity are still protecting the wood, but they’ve lost their looks. In the real world, all of the one-part varnish and varnish alternative test panels would be due for a maintenance coat, and some-like HMG K Type Varnish, West Marine WoodPro Plus (rebranded Epifanes Rapidclear), and Ace Spar Varnish-would be overdue.

The biggest overall decline was within the one-part varnish test group: Not a single one rated better than Fair for coating integrity or gloss retention, and nearly half of the test field was retired after this rating round. Just six months before, eight of the 19 products rated Good for coating integrity and six rated Good for gloss retention. In 12 months, seven dropped from an Excellent coating integrity to a Fair.

The one-part varnishes offering the most protection after two years are Detco Crystal, Le Tonkinois Vernis, and Pettits Z-Spar Captains 2067. However, their extended protection comes with tradeoffs: Detco rated only Fair for application, Le Tonks gloss started to slip after one year, and Pettits 2067 started losing its original color after 12 months.

One hardware store varnish has surprisingly held its own over the long haul: Minwax Helmsman Spar Urethane. At half the cost of the Recommended one-part varnishes, Minwax slacked in the color retention department, but it has proven its multi-season durability.

Four of the nine varnish alternatives have been voted off The Rack after two years, and none performed well enough to earn our recommendation for two-year wood protection.

The Cetol products are still at the head of the pack, albeit a somewhat mangy-looking pack. The cloudy, opaque look of the Cetol Marine and Marine Light products may not appeal to everyone, but the fact they’ve maintained their color for more than a year is a good example that higher-solids finishes tend to offer better UV protection.

The Cetol Natural (with gloss) test panel fell from a Good coating integrity six months ago to being dropped from testing. Its performance mirrors what we’ve seen in the field: Give it a little loving once a year with a scrubby pad and a fresh coat, and it’ll last the long haul.

Its taken two years, but the two-part varnishes are finally starting to show their age. Surprisingly, the first products to be dropped from this group are two that performed well in past PS tests: Bristol Finish and Honey Teak. This is likely because the life of a wood finish in Florida is always going to be shorter than in our past test locales in New England.

The other two-parts are still holding up well, with Interlux Perfection and Nautiking Nautithane offering uncompromised protection and better-than-expected gloss after 24 months. Perfection has been reformulated since the test began and is now sold as Perfection Plus.

The temporarily discontinued (since 2009) Smiths Five Year Clear has also proven to be a top-notch finish, but its not available at this time.

While HMG Acrythane XSC didn’t earn our Recommendation this time, it was a top 18-month finish, it still looks good, and it costs less than the Nautithane.

Conclusions About Exterior Varnishes

After two years of testing, we’ve come to accept that perhaps there’s no Holy Grail of exterior wood finishes. It would appear, unfortunately, that we can’t have it all: easy to apply, easy to maintain, long-lasting protection, and a budget-friendly price tag. The reality is that, like much in life, wood protection is all about compromise and balancing your needs with your wants.

There’s no one-size-fits-all solution, and the boat owner who finds gratification in the wet, glossy look of a two-part varnish borne of painstaking preparation and careful application will weigh our test data much differently than the one who regards brightwork maintenance as a masochistic endeavor. For the latter, we recommend seeking out a varnish alternative (easy to apply, easy to maintain) that suits your tastes. With modest maintenance, the Cetol products with gloss overcoats have proven to be the most durable.

For areas where slippery-when-wet coatings wont do, Cetol Natural (without gloss overcoat) or our top-pick teak oil, Star brites Tropical Teak Sealer (classic teak) should be considered. The Star brite will need to be reapplied every three or four months.

If you’re looking for a harder, more abrasion-resistant finish that’ll make it past the year mark, check out the top one-part varnishes like Detco Crystal or Pettits Z-Spar Captains 2067. Boat owners in sailing areas that see less sunshine than our Florida test site should also consider Pettits Flagship 2015 or Captains 1015. One-part varnishes require a little more work upfront and quick attention when they are scratched or dinged, but they also offer a more traditional, high-gloss look. The one-part varnishes in our test slipped dramatically after a year and half, so we suggest an annual maintenance coat, whether they look like they need it or not.

As this test has shown, when it comes to long-lasting protection and gloss, two-part varnishes just can’t be beat. They may be a pain to apply-and should you let the coating fail, you had better invest in a heat gun-but their durability is unmatched.

The top two-part after two years of testing was Interlux Perfection. Because we’ve not yet tested the reformulated Perfection, the top pick honors go to Nautikings Nautithane. While its price tag ($120 per quart kit) is a bit hard for most of us to swallow, Nautithane earned across-the-board Good ratings after two years.

Practical Sailor often supplements panel testing with product challenges aboard our test boats to see whether top products still earn their keep in the real world and to try out new products. Two such evaluations are our exterior wood finish tests.

In the January 2011 issue, we introduced a head-to-head matchup of varnish alternatives—market-newcomer PolyWhey from Vermont Natural Coatings versus perennial favorite Interlux’s Sikkens Cetol Natural Teak—that had been applied to our Cape Dory 25 test boat. For that test, we’ve just let nature run its course: no band-aid touchups, no maintenance coats, no freshwater rinses, no TLC at all.

Comparatively, we’ve been testing Cetol Natural aboard our Chesapeake Bay-based Union 36 test boat, where it was laid on with the Cetol gloss overcoat in 2008; in this evaluation, testers have applied annual maintenance coats and given the coating regular TLC. Here’s the latest on both of these tests:

PolyWhey vs. Cetol Death Match

In the fall of 2010, testers applied three coats of Caspian Clear PolyWhey to the coamings and companionway trim on the Cape Dory, which is sailed several times a week and lives on a mooring in Sarasota Bay, Fla. We also applied Cetol Natural to the boat’s toerail, and previously had applied it to the tiller and forward hatch trim.

PolyWhey is a unique wood finish that uses whey protein, a by-product of the cheesemaking process, as a binder. It’s touted as a more eco-friendly and more sustainable coating than petroleum-based polyurethanes, which can have up to 75 percent more volatile organic compounds (VOCs).

Consistently among the top varnish alternatives in PS’s tests, Cetol Natural is not as muddy-looking as its predecessors, Cetol Marine Light and Cetol Marine—like the Caspian Clear, it allows the wood’s natural grain to show and has a low gloss.

As far as application, both the Cetol and PolyWhey are quick and easy to apply, with much shorter recoat times than hard varnishes and less (or no) sanding between coats. The main difference that we found in these two finishes was with durability.

The PolyWhey turned out to be a much softer coating than the Cetol. It held up for about two months, but after three months, it was in need of a recoat, and at six months, it needed a total takedown—and Cetol had emerged as the death-match victor.

The PolyWhey on the coaming was the first to go: Where crew backs often lean against the wood, the finish was all but gone after four months. The PolyWhey on the companionway slides held on for about that long, but by six months, they were ready for a do-over as well.

The Cetol on the toerail was in need of a few touchups after six months, mostly in areas where fenders and docklines came in contact with it. But the tiller and hatch trim were still fairly well-protected almost a year after application. Although we’d recommend a maintenance coat at this point, testers plan to see how many more months we can eek out of the coating before we reach the point of no return.

Bottom line : We applaud VNC’s efforts to offer a “green” wood finish—and their creative recycling of dairy industry “trash”—but we can’t recommend it over Cetol for an exterior coating in the marine environment.

Cetol with Overcoat

Testers applied three coats of Cetol Natural with Cetol Marine Gloss overcoat to the Union in March 2008. Once a year, we scuff it up with a 3M pad, give it a freshwater rinse, and brush on a maintenance coat.

Compared to a clear, glossy varnish, it looks decent and the maintenance regimen is more realistic for our tastes and available time. However, one downside to softer, varnish alternative coatings—even those with an overcoat—is that they don’t stand up as well as hard finishes to dings and abrasion. Example: The Union’s toerail has one place in need of touching-up where a fender line wore away the finish. (See photo above.)

Bottom line : The Cetol Natural with overcoat has held up very well. While applying the topcoat may mean added effort, both our panel tests and test-boat evaluations have shown that the coating will last much longer and need fewer bandaids if the soft Cetol is protected with the semi-hard topcoat.

Teak oils and other naturally based finishes like PolyWhey, need maintenance coats every few months. Their chemical cousins, however, like Cetol, have proven they can offer good protection with only annual nurturing and the occasional touchup.

- C-Tech Marine (Bristol)

- Deft Finishes

- Le Tonkinois

- Premapro (Coelan)

- Signature Finishes

- Smith’s Five Year Clear

- Vermont Natural Coatings

- West Marine

- Woodplus Marine

RELATED ARTICLES MORE FROM AUTHOR

17 comments.

I’m surprised you didnt include Alwood from Awlgrip

Search Awlwood on the website. We have a couple reports. October 2014 (chandlery), and June 2015 issues. Download the PDFs, because the tables haven’t been loaded online yet. It is broadly comparable to Sikkens Cetol.

opps, Awlwood not alwood

All very interesting……The “bottom line” is just flush the line in fresh water.

Thank you for the great info. I am going order year of Practical Sailor.

What is your opinion of covering a 2 part varnish with a one part?

It is certainly a comprehensive test. I’ve taken the journey of sticking with one of your “good” one part varnishes, Epiphanes Wood Finish gloss 10 coats with Epiphanes final two matte finishes. I’ve been quite impressed with it over the past 8 years on both my Cape Dory Typhoon and my Alberg 30. My conclusion is, read your directions carefully and be patient through all phases of application. Teak requires a caregiver! Great read especially during this pandemic period.

Great review. Your test is useful for me because I want to buy but dont know which product is the best. I must say that I like all of those mentioned above and price is really cheap. It’s always good to hear other input.

You missed out Pettit’s Gold, a water-based varnish. I have used it, and it’s great. For long life? Too soon to tell. Cetol has mostly been a disaster, especially with the Gloss overcoat. Applying Cetol can be tantamount to vandalism.

That’s really nice post. I appreciate your skills. Thanks for sharing.

Did you continue with testing to date, I am after a product that want yellow or bloom because of constant direct sunlight. I am in the North West of Australia where the temp at it’s coolest is 30+ Celsius for a couple of months and peeks over 50 + Celsius for a lot more than the couple of cooler months.

I use Rust-Oleum 207008 Spar Varnish. So much better than those water-based varnishes. This stuff protects almost forever. We used to use this kind of spar varnish in the Navy to protect the woodwork exposed to salty air.

The Interlux Varnish became my favorite varnish on teak fixtures when I tried it out 2 years ago. This is because of the immense difference it makes in the way it lends my pulpit or anything made of teak with a sophisticated, good-as-new finish.

It’s strange that you call out Pettit Z-Spar Captains 2067 as a top performer in the conclusions, but it’s not shown in the chart. Those Pettit products that are included in the chart don’t appear to be top performers. I’m confused.

After less than a year the Bristol finish I used on my boat looks terrible and will have to be removed. The folks at Bristol are absolutely no help at all. Their disclaimer is that they know nothing about boats. I most strongly advise against using this product for marine application. I have photos taken immediately after application, two months after, and eight months after if anyone is interested. By the way, the problem manifested on well prepped old teak and well prepped new teak. Could have just been a bad batch of finish but as I said, the folks at Bristol were no help. I ADVISE AGAINST USING BRISTOL FOR MARINE APPLICATIONS

I’m certain that the analysis of marine varnish was expensive and time consuming but one area that could benefit many subscribers if it was conducted continuously. Practical Sailor is the only place that I can rely on for accurate, up-to-date information on the products I need and use.

This is an important maintenance topic to me. Maintaining brightwork is a lot of labor. This article was last updated in June 2020. I would appreciate an update. I have been using Epifanes clear high gloss varnish for the last five seasons. It gives a good finish but it needs to be touched up one a year even though my boat is under cover for six months of the year. I sail on Lake Erie.

LEAVE A REPLY Cancel reply

Log in to leave a comment

Latest Videos

The Cheap Big Cruising Sailboat – Endeavour 42

Marine VHF Radio – What You Need to Know

Pearson 37 & 37-2 – Behind the Curtain

How To Test a Boat Engine

Latest sailboat review.

- Privacy Policy

- Do Not Sell My Personal Information

- Online Account Activation

- Privacy Manager

What’s the Best Varnish for Your Yacht?

Looking for the best yacht insurance ? Buy your sailing yacht insurance online at Admiral Marine, or contact our expert team for advice.

Varnishing your yacht is an essential part of its care and maintenance. The benefits are twofold: yacht varnish protects your boat from the elements, while also giving it a beautiful shiny finish. But with so many different yacht and marine varnishes to choose from, it can be difficult to know which one is best for your boat.

In this article, we’ll run through some of the most popular types of yacht varnish on the market to help you choose the right option.

What is Yacht Varnish?

Yacht varnish is an extremely durable solvent-based coating that is designed to protect the wood that yachts are made of and stop it decaying over time. Most varnishes are made up of a penetrating oil, resin and solvent. Although most yacht varnish is applied with a brush, it is possible to buy yacht varnish spray.

Different Types of Yacht Varnish Finish

There are many different types of finish to choose from, so you’ll need to know a little about them to decide which is the best yacht varnish for you.

Designed by Freepik https://www.freepik.com/

Yacht Varnish Brands

There are various brands that produce yacht varnish. Here are a couple of the most popular:

Screwfix Yacht Varnish

Screwfix is a retailer in the UK that sells a variety of products, including hardware and building supplies. They may carry different brands and types of yacht varnish. Yacht varnish provides resistance to water, UV rays, and other environmental elements. Yacht varnishes often contain additives to enhance their durability and performance in marine conditions.

Ronseal Yacht Varnish

A durable, long-lasting marine varnish for wood that flexes with the movement of the wood and resists peeling and cracking. This varnish is slightly more pricey than the Screwfix varnish, but gets great reviews. You can buy the Ronseal brand of yacht varnish in B&Q and other retailers.

How to Varnish Your Yacht

Varnishing a yacht is fairly straightforward, if a little time-consuming. First you’ll need to carefully sand down the entire surface that you want to varnish to get it looking smooth. Then use a soft brush to wipe off any excess dust and debris, since you don’t want it getting trapped in the varnish.

Finally, use a paintbrush to coat the yacht with varnish. Leave it to dry for the recommended amount of time on the tin, then apply additional coats as required. Always check the instructions of your varnish type, and if unsure consult with an expert before starting.

Yacht varnish is solvent-based and contains toxic chemicals, which means it should not be used for varnishing animal enclosures (for example, rabbit hutches or reptile enclosures).

- What is yacht varnish used for? Yacht varnish is used for sealing and protecting wood on boats and yachts. It is also commonly used for outdoor items such as wooden doors, window frames or pergolas.

- What type of varnish is yacht varnish? Yacht varnish is a solvent-based outdoor varnish that is extremely durable. It is usually made up of tung oil and polyurethane resin.

- What is the best varnish to use on a boat? The type of varnish that is best for your boat will depend on the type of wood your boat is made from and the finish you are looking for. Tung oil varnish is a safe bet for most boats, or you may prefer to use a one-part polyurethane varnish for added durability.

- What is the difference between yacht varnish and outdoor varnish? In general, yacht varnish dries quicker and is designed for marine conditions, so it’s likely to be more durable than outdoor varnish. However, yacht varnish is unlikely to have an anti-slip formulation, making it unsuitable for decking around the home.

Admiral Marine is a trading name of Admiral Marine Limited which is authorised and regulated by the Financial Conduct Authority (FRN 306002) for general insurance business. Registered in England and Wales Company No. 02666794 at 1st Floor, One The Square, Temple Quay, Bristol, BS1 6DG

If you wish to register a complaint, please contact the Compliance and Training Manager on [email protected] . If you are unsatisfied with how your complaint has been dealt with, you may be able to refer your complaint to the Financial Ombudsman Service (FOS). The FOS website is www.financial-ombudsman.org.uk

+44 (0)1722 416106 | [email protected] | Blakey Road, Salisbury, SP1 2LP, United Kingdom

Part of the Hayes Parsons Group

Which Yacht Varnish Is Best For My Boat?

Yacht varnish is a specialized type of varnish that is often used on boats. It has several advantages over conventional varnish, which is why it is becoming more and more popular among boat owners. In this guide, we will discuss the benefits of yacht varnish. We will also answer some common questions about yacht varnish. So if you are interested in learning more about this topic, keep reading!

Yacht varnish is a type of varnish specifically designed for boats. It is typically made from a tougher resin that can withstand the harsh conditions that boats are exposed to, such as salt water and sunlight. Yacht varnish also often contains UV inhibitors to help protect the wood from fading and other damage caused by exposure to sunlight. Conventional varnishes are not as durable as yacht varnish and will not stand up to the same conditions. This makes them less suitable for use on boats. However, they can still be used for other applications, such as furniture or around the garden.

Which types of varnish to use on my boat?

Marine varnish can be divided into three different types, each with its own perfect uses. Yacht owners choose to use one or all of these types for better performance.

Tung Oil-based varnish

Is the most popular type among yacht owners who take boat maintenance seriously. International Schooner or Goldspar Boat Varnish are both oil-based varnishes that coats the wood evenly leaving a smooth finish while requiring minimal preparation work before it can be applied. This only requires a couple of coats. Is advisable to lightly sand the surface between coats to achieve the highest quality glossy finish. The smooth, high gloss finish will protect teak parts from water stains and help to maintain their appearance over time! Its UV protection helps prevent mould growth too which is especially important in wetter climates. Oil-based varnish is easy to apply and can be repaired by sanding and re-oiling the wood, meaning it will last longer than other conventional varnishes. It's also easier to apply compared with water-based yacht varnish which requires no sanding or priming before application.

Water-based boat varnish

Often used on marine boats where there is not much exposure to agitation or rubbing, making oil-based varnish too heavy for use. This yacht varnish type tends to leave a thin, powdery residue that needs sanding down after drying but offers better penetration into the wood than its oil counterpart. Polyurethane boat varnish - is much more hard-wearing than oil or water-based yacht varnishes. Stronger than oil-based or water-based yacht varnish, polyurethane yacht varnish tends to dry quickly and offers an ultra-hard surface that is resistant to impact, scratching and denting. This yacht varnish type has a high gloss tough finish so it's best suited for areas of the boat that are exposed to more wear and tear. This type of varnish can also be divided into two categories as one part polyurethane boat varnish and two-part polyurethane varnish.

One Part Polyurethane Varnish

The yacht varnish that is most commonly used for yacht paint jobs. The yacht varnish offers a quick drying time and can be easily re-coated within hours between each coat. It should be noted that due to its rigidity it is not recommended to be used for painting highly flexible wooden areas as it might crack in time leaving the wood exposed to elements. Two-Part Polyurethane Varnish - is the varnish with longer working times, making it easier to apply on larger boats. It's advisable to use only one part polyurethane yacht varnish for smaller projects as two-part yacht varnishes tend to leave an unprofessional finish when applied by hand. This type of varnish is extremely tough and consists of two products mixed together. It offers very good protection from moisture and UV damage but the same as the above this is not suitable for some areas on your yacht (such as spars) and it will crack as the wood moves and will leave the wood exposed to the elements.

Is yacht varnish waterproof?

Yes, yacht varnish is typically waterproof. This makes it a good choice for protecting boats from the elements. It can also help to keep the wood of the boat looking its best for longer.

Does yacht vanishes need a primer?

No, yacht varnish does not typically need primer. However, it is a good idea to test it on a small area of the surface you are going to varnish to make sure it adheres properly. If you do decide to use primer, make sure it is designed for use with yacht varnish.

Does yacht varnish seal wood?

Yes, yacht varnish seals the wood. It forms a protective barrier that helps to keep the wood from damage and keeps it looking its best for longer.

How long does yacht varnish last?

The lifespan of yacht varnish varies depending on the brand and the conditions it is exposed to. However, it typically lasts for several years, anywhere from two to three years before you need to apply a new coat or two. Some varnishes obviously last longer than others depending on the area where they will be applied.

Which is better? Woodstain or yacht varnish?

There is no simple answer to this question as it depends on the specific application and the needs of the user. However, in general, yacht varnish is a better option for protecting wood from the elements and keeping it looking its best. It is also typically more durable than wood stain, which makes it a better choice for boats.

Why is it important to sand between coats?

It is important to sand between coats of yacht varnish because it helps to create a smooth, even surface. This makes the final coat of varnish look its best and helps to protect the wood from damage.

How many coats should I apply?

The number of coats you should apply depends on the specific product you are using and the area you are varnishing. In general, two to three coats are sufficient. However, it is always a good idea to follow the manufacturer's instructions for the best results.

What type of finish can you get?

There are three types of finish on boat varnish: gloss, semigloss, and satin. Each one has its own benefits and drawbacks, so it is important to choose the one that best suits your needs. Gloss finish is the most durable, but it is also the most reflective. This can make it difficult to see in bright sunlight. The semigloss finish is less reflective than gloss, but it is still quite durable. It is a good choice for areas that receive moderate amounts of sunlight. The satin finish is the least reflective and also the least durable. However, it can provide a more natural look to the wood. It is a good choice for areas that do not receive a lot of sunlight.

Can you paint yacht varnish over wood stain?

Yes, you can put yacht varnish over the wood stain. However, it is important to make sure that the stain is fully dry before applying the varnish. Otherwise, you may end up with a sticky mess.

How long does it take for yacht varnish to dry?

The drying time for yacht varnish varies depending on the brand and the conditions it is used in. In general, you can expect it to take anywhere from six to eight hours to fully dry. However, it is always a good idea to read the manufacturer's instructions for the best results.

Can you thin yacht varnish?

Yes, you can thin yacht varnish if it is too thick. However, you should only use a thinner that is specifically designed for use with yacht varnish. Otherwise, you may end up with a poor-quality finish.

What is the best way to remove yacht varnish?

The best way to remove yacht varnish depends on the type of finish you have. If you have a glossy finish, you can use a polishing compound. For a semigloss or satin finish, you can use sandpaper. In general, it is best to remove yacht varnish with a power sander. However, you can also remove it by hand if you are careful.

Can I apply a new coat over the existing varnish?

Yes, you can apply a new coat of varnish over the existing varnish. However, it is important to make sure that the old coat is in good condition. Otherwise, you may not get the desired results.

Does yacht varnish go yellow?

Yacht varnish is designed to keep your boat looking good as new even throughout the season's hottest and coldest temperatures. The UV inhibitors prevent yellowing, which can otherwise occur due to exposure to external factors like sunlight or rainwater on a dock; they also remain slightly soft so that it will not crack when expanding or contracting with changes throughout each year. Liquids such as engine oils may cause blistering if left unprotected by an anti-blister agent like silicone lubricant (which contains graphite).

Is yacht varnish oil or water-based?

Yacht varnish is typically oil-based. This makes it more durable and resistant to fading. However, water-based varnishes are also available. These are less durable but easier to apply.

So which yacht varnish is right for you?

Choosing the right yacht varnish depends on how much time you want to put into maintaining your boat as well as its location. We stock a wide range of varnish suitable for any type of wood on your vessel.

More articles

Independently owned company.

Copyright © 2022. Fox's Chandleries Limited. All Rights Reserved. Registered in England and Wales, Company Number 03914760, our VAT registration is 939 9732 58.

Quick links

Contact information.

Fox's Chandlery Fox's Marina The Strand, Ipswich Suffolk, United Kingdom IP2 8SA 01473 688 431

Supported payment methods

Subscribe and receive exclusive information and offers!

123 John Doe Street Your Town, YT 12345

Store Hours Sun: Closed Mon-Fri: 9:00 - 17:00 Sat: 10:00 - 13:00

What to expect at pickup

Closing at 5pm

Closing at 1pm

Marine Plywood vs. Regular Plywood: Choosing the Right Material for Your Boat

Overview of Marine Plywood and Regular Plywood

In my 20 years of boating experience, I’ve frequently encountered the decision between using marine plywood and regular plywood for various projects. Understanding the distinctions between the two is crucial for durability and safety onboard.

Marine Plywood:

- Composition: Typically made from hardwood veneers like birch or mahogany, bonded with waterproof adhesives.

- Durability: Designed to withstand moisture and resist rotting, even in constant water exposure scenarios.

- Applications: Ideal for boat decks, docks, and other structures that directly contact water.

Regular Plywood:

- Composition: Constructed from a mix of wood species, bonded with adhesives that may not be waterproof.

- Durability: More susceptible to water damage, can warp or delaminate upon prolonged moisture exposure.

- Applications: Suited for indoor use or applications where water exposure is minimal and temporary.

| Feature | Marine Plywood | Regular Plywood |

|---|---|---|

| Voids are rare, which provides uniform strength and stability. | May contain voids, potentially leading to weak spots. | |

| Thicker veneers offer better resistance to breaking and cracking. | Thinner veneers, less effective in preventing breakage. | |

| Uses waterproof glue to maintain its laminated structure in moist settings. | Standard adhesive may fail in wet conditions. | |

| Generally more expensive due to its high quality and durability features. | More affordable, but with a trade-off in moisture resistance. |

When selecting plywood for a boat, it’s essential to match the material to the intended use. Although marine plywood might come at a higher cost, its long-term reliability in marine environments often justifies the investment. In my professional judgment, for marine applications, the extra cost of marine plywood pays off through performance and lifespan.

Core Differences Between Marine and Regular Plywood

In my twenty years of boating experience, I’ve learned the importance of choosing the right plywood for the job. Marine and regular plywood serve different purposes, crucially distinguished by their material composition, water resistance, durability, strength, and adherence to specific certifications and standards.

Material Composition

Marine Plywood : I’ve observed that marine plywood is made using high-quality hardwood veneers with no voids, which are layers free of imperfections. Typically, the adhesives used are waterproof and stronger to sustain a marine environment.

Regular Plywood : Contrarily, regular plywood may include a range of wood types, including softwood, and often contains voids within its layers, which can weaken its structure.

Water Resistance

Marine Plywood : In my projects, I rely on marine plywood for its superior water resistance. This plywood does not deteriorate in wet conditions, making it indispensable for boats and marine applications.

Regular Plywood : While there are exterior grades of regular plywood with some water-resistant properties, they do not match the impermeability of marine plywood and should not be exposed to persistent moisture.

Durability and Strength

Marine Plywood : My experience in boat repairs has demonstrated that marine plywood offers enhanced durability and strength due to its high-grade wood and the meticulous construction process it undergoes.

Regular Plywood : It can be sturdy depending on the grade, but regular plywood is generally less resistant to bending, warping, and breaking, especially under stress in moist conditions.

Certifications and Standards

Marine Plywood : Standard certified marine plywood must meet rigorous standards such as BS 1088 or similar, ensuring consistent quality suitable for marine use.

Regular Plywood : This type lacks stringent marine standards, although it may meet other certifications relevant for indoor or less demanding outdoor uses.

Considerations for Using Plywood in Boat Building

In my two decades of experience in boating and working with boat structures, selecting the right type of plywood is crucial. It ensures durability, safety, and overall performance of the vessel.

Suitability for Boat Structures

Marine plywood, which has only two grades: A and B , is designed specifically for the marine environment. My experience has taught me that marine plywood is essential for parts of the boat that require structural integrity due to its high-quality veneers and fewer defects. Regular plywood, with grades going as low as D, is not suited for high-load bearing components.

Exposure to Elements

Boats are constantly exposed to moisture, which can lead to the degradation of materials. Marine-grade plywood is nearly 100% waterproof and ideal for building piers, docks, and boat hulls. On the other hand, regular plywood would need additional sealing and treatment to withstand such conditions, and even then, may not offer the same level of protection against rot and decay.

Required Treatments

Before installing plywood in a boat, certain treatments are necessary. For instance, the application of sealants or resins on marine plywood extends its life expectancy by providing an added barrier against water ingress. Details such as the recommended thickness of plywood for the boat floor and the specific type of sealant can vary depending on the size of the boat and exposure to elements. Regular plywood, even when treated, may not achieve the same longevity or strength as properly treated marine-grade plywood.

Cost Comparison and Availability

As a boat enthusiast with 20 years of experience, I’ve worked extensively with both marine and regular plywood. When it comes to cost and availability, there are distinct differences between the two that are important to weigh when choosing materials for boating projects.

- Cost: Generally, marine plywood is significantly more expensive. Depending on the thickness and quality, prices can range from $70 to over $200 per sheet.

- Availability: It’s not as widely available as regular plywood and may incur shipping charges if it’s not stocked locally.

- Cost: More budget-friendly, a sheet can typically cost between $10 to $50.

- Availability: Quite easy to find at most lumber yards and home improvement stores.

It’s clear that if your project requires exposure to water and durability against harsh marine environments, marine plywood is the better choice despite its higher price point. It’s constructed with waterproof adhesives and often made of hardwoods, which maximizes its resistance to rotting in wet conditions.

On the other hand, if your project is less exposed to the elements or if you’re working within a tight budget, regular plywood can be substituted in non-critical applications. However, it won’t have the same resilience as marine plywood and may not last as long in a marine environment.

Making the right wood selection for your boat depends largely on these factors. Ensure you consider both the immediate cost and long-term value that marine plywood can offer, especially if you’re looking to maintain structural integrity on water.

Maintenance and Lifespan of Marine and Regular Plywood

In my 20 years of boating experience, I’ve learned that maintenance and lifespan are critical factors when choosing between marine and regular plywood for boat construction.

Marine Plywood : This material is specifically designed for water exposure. It’s made with waterproof adhesives and typically has a higher grade of veneer. Proper care is essential; marine plywood should be regularly sealed to prevent water damage.

- Expected Lifespan : With diligent maintenance, it can last 30 to 40 years in marine environments.

- Maintenance Tips : Annual inspections for damage, sealing with quality marine varnish, and storage away from direct sunlight when not in use.

Regular Plywood : More susceptible to water damage but can be used for short-term or light exposure applications. If chosen for outside use, it requires diligent sealing and preventive care.

- Expected Lifespan : If sealed and maintained properly, regular plywood may last 20 to 30 years outside.

- Maintenance Tips : Apply weatherproof coatings, regular inspections, and immediate repair of any damage.

| Plywood Type | Maintenance Frequency | Coating/Sealant Type | Possible Lifespan (Years) |

|---|---|---|---|

| Marine | Bi-annual | High-quality marine | 30-40 |

| Regular | Annual | Weatherproof exterior | 20-30 |

I prefer marine plywood for my boating projects due to its resilience and reliability. Even with its higher cost upfront, the extended longevity and reduced frequency of repairs make it a worthwhile investment.

Environmental Impact of Plywood Use on Boats

In my 20 years of boating experience, I’ve observed various materials used in boat construction and their impacts on the environment. Marine plywood and regular plywood are two such materials, each with different implications for our planet’s health.