- NEW : Our Second-Hand catamarans

- New Windelo 50 Adventure

- New Windelo 50 Yachting

- New Windelo 50 Sport

- New Windelo 54 Adventure

- New Windelo 54 Yachting

- New Windelo 54 Sport

- Our Second-Hand catamarans

- The Windelo Innovations : performant, comfortable and eco-friendly catamarans

- Ocean Future : our ecological approach

- The Windelo Services

- Charter a Windelo catamaran

- The Windelo Shipyard

- Windelo Team

- Recruitment : Join the Windelo team

ELECTRIC HYBRID DRIVE SYSTEM For silent ecological sailing

Windelo catamarans travel silently even when under power, thanks to their electric hybrid drive system . Enjoy the sound of the waves and wind while not disturbing the wildlife as you set sail from your dream anchorage to a new destination. With our electric catamarans , no more exhaust fumes and vibrations – sailing is now a really pleasurable clean, environmentally-friendly experience .

The Windelo catamarans are fitted with two 20kW electric motors from Bellemarine . With an electric propulsion, there’s no need to warm up the electric motor. You have full power from the moment you switch it on.

Motor: A reliable high-performance electric hybrid drive system

Electric motor with a good cruising range.

- At 6 knots, the Windelo 50 has a range of nearly 3 hours and 45 minutes and roughly 22.7nm per day with an 1120Ah battery bank.

- At 7 knots, the Windelo 50 has a range of nearly 2 hours and 17 minutes and roughly 15.47nm per day with an 1120Ah battery bank.

When the energy consumed is not compensated by renewable energies , the 18kW backup 500L diesel generator(s) start(s) up to supply the electric motors and recharge the batteries . The generator is in the aft engine bays and communicates with the Boat Management System . It starts up automatically when the batteries are low and/or when the power required is greater than the power the batteries can supply. So, the full cruising range of our catamarans on the motor is 1100 nautical miles . The generator can also be started manually by the skipper in 2 different modes:

- Cruising range mode : for example, the skipper wishes to start his generator to increase his cruising range when there is no wind.

- Recharge mode : the skipper starts his generator, which automatically switches off when the batteries are fully charged.

SALES MANAGER

Windelo is a new conception brand of innovative catamarans. Ecology is at the heart of the company with the ambition to significantly reduce the environmental impact of our boats. A range of 44 to 60 foot catamarans offering sailors the opportunity to sail with pleasure and safety on eco-friendly boats.

In full development, we are hiring a sales manager:

JOB AND MISSIONS: Managed by the director of the company, and in connection with our various services and partners, you are a key player in the launch of this new brand.

Real project manager: 1. You co-build the Windelo sales and services office, 2. You recruit, train, and drive progressively a team of passionate experts, 3. You develop and innovate in the strategy of selling Windelo boats in Europe, 4. You recruit and lead a global network of sales partners, 5. You co-build and animate the company’s service strategy: port mapping places; insurance and financing; training; owner’s manual etc.

YOUR PROFIL 1. Passionate about sailing, you practice regularly, 2. Your sense of service and customer leads you to satisfy your customers every day, 3. You are enthusiastic and motivated to work in a start-up, 4. You have 2 to 5 years’ experience in the sale of boats, 5. Bilingual French – English, you also speak a third language: German, Italian, or Spanish.

EVOLUTIVE JOB Director of sales

AVAILABILITY / PLACE OF WORK 1st Quarter 2019 / Occitanie Region, Canet en Roussillon FRANCE

TYPE OF CONTRACT AND REMUNERATION Permanent contract / fixed to be defined according to experience + variable.

If you are a passionate of sailing and this challenge to participate in the development of a company in full creation arouses your enthusiasm, welcome to send your application by e-mail to: contact@windelo-catamaran.com

RESPONSABLE DES VENTES

Windelo consiste en la création d’une nouvelle marque de catamarans innovants. L’écologie est au coeur de l’entreprise avec pour ambition de réduire fortement l’impact environnemental de nos bateaux. Une gamme de catamarans de 44 à 60 pieds offrant aux marins la possibilité de naviguer avec plaisir et sécurité sur des bateaux éco responsables.

En plein développement, nous recrutons un(e) responsable des ventes

POSTE ET MISSIONS

Managé(e) par le directeur de l’entreprise, et en lien avec nos différents services et partenaires, vous êtes un acteur clefs du lancement de cette nouvelle marque. Véritable chef de projet :

1. Vous co-construisez le bureau des ventes et des services de Windelo, 2. Vous recrutez, formez, et animez progressivement une équipe d’experts passionnés, 3. Vous développez et innovez dans la stratégie de vente des bateaux Windelo en Europe, 4. Vous recrutez et animez un réseau mondial de partenaires de vente, 5. Vous co-construisez et animez la stratégie de service de l’entreprise : mapping des places de port ; assurance et financement ; formation ; entretien ; manuel du propriétaire etc.

VOTRE PROFIL 1. Passionné(e) de nautisme, vous naviguez régulièrement, 2. Votre sens du service et du client vous anime pour satisfaire vos clients au quotidien, 3. Vous êtes enthousiaste et motivé(e) à l’idée de travailler en équipe dans une « start-up », 4. Vous disposez de 2 à 5 ans d’expérience dans la vente de bateaux de plaisance, 5. Bilingue français – anglais, vous maitrisez également une troisième langue : allemand, italien, ou espagnol.

POSTE EVOLUTIF Directeur des ventes

DISPONIBILITÉ / LIEU DE TRAVAIL 1ier Trimestre 2019 / Région Occitanie, Canet en Roussillon FRANCE

TYPE DE CONTRAT ET REMUNERATION CDI Cadre / Fixe à définir selon expérience + variable.

Si vous êtes un(e) passionné(e) de l’univers du nautisme et que ce challenge de participer au développement d’une entreprise en pleine création suscite votre enthousiasme, merci d’adresser votre candidature par e-mail à : contact@windelo-catamaran.com

As part of the creation of new types of catamaran made in Occitanie, an audacious choice of ecological innovation has been selected in partnership with the Materials Center of « Mines d’Alès » (C2MA – IMT MINES ALES) (Gard, France). It’s a question of combining ecological performance in terms of minimizing the environmental footprint and structural resistance, and this, in a global approach of circular economy on all parts of the boat. To do this, and in connection with the IMT MINES ALES, Windelo has relied on the use of secondary raw materials, competitive virgin petroleum-based materials, that fully comply with the specifications in terms of mechanical performance. This is a real first step to the development of a 2.0 fleet ships fully integrated into the challenges and ecological challenges of the 21st century.

Associated with an ecological approach of circular economy integrating a not insignificant part of competitive secondary raw materials from virgin materials, the architectural design and the resistance of materials on the new Windelo catamarans are mechanically tested in the Materials Center of « Mines d’Alès » (C2MA – IMT MINES ALES) (Gard, France) in connection with the architects and designers of the project. The design of the ship, and in particular the hulls and bows, go through a search for efficient structuring and arranging of materials composing it, combined with a mechanically optimized geometrical assembly. To this end, specific test developments, such as the study of distortion of the structure and of the panels constituating the hull of the ship, are studied by digital image correlation techniques coupled with standardized strength tests.

Founder of Catana

“The cruising program for this new boat raises the question of the antagonism between the search for performance under sail and the pleasure of navigation, and the development of pleasant living spaces. The originality of the answer is provided here in the arrangement of the cockpit bringing together the helm and maneuvers to the center of the boat and in the arrangement of living space that occupies the rear of the nacelle.

Just behind the mast the outer cockpit offers two helm stations protected from the wind and spray, a beautiful view of the sails and bows, and allows to have all the maneuvers on hand while limiting the needs to circulate on the bridge. Out of navigation, the cockpit can be more widely protected from the outside and open to the rear space.

Fully opened behind this cockpit, we have not developed two living spaces duplicating one inside the other but a single large space which is ajustable. We have focused our efforts on the geometry of the material and visual limits of this space and on the opening kinematics of the bays. Once opened, they “disappear” to transform the interior into an exterior. The generosity of these openings also allows to modulate the ventilation of this space by playing on a wide range of opening on its four sides

This work on the modularity and the disappearance of limits is found at the extreme rear of the nacelle, with an articulated platform to the davits transforming it into a floor when anchored, and in the rear cabins, whose wide turning porthole eliminates the angle between side plating and back side. The cabin space is therefore generous despite the relative narrowness of the hulls.

All these choices allow us to combine a contained hold of the nacelle, pledge control of the weight estimate, to a generous living space, with a central part given to navigation and maneuvering. The slenderness of the forward spikes, the significant free height under the platform, and the attention paid to the centering of the masses, complete the marine qualities expected for an offshore navigation program.

The other originality of the project brought by this new construction site is in the approach of “eco-design” on materials and construction. Strongly limiting the use of molds, the latter brings a greater margin of freedom in the variations and evolutions of the boats thus conceived. ”

Christophe Barreau et Frédéric Neuman

Architects and Naval Engineers

Who could know if it is the father or the son who is the most passionate? It doesn’t matter. The important thing is to write an innovative project within a family culture, for today and for generations to come. Hand over the guiding light, this is Olivier Kauffmann’s will. “At first I wanted to make my own boat, for me and my family; go on trip around the world living on a efficient and pleasant catamaran. I dreamed of a new quality of space. Today, the dream has matured, and I want to share it with the great family of sailors. »

Windelo is the desire to expose us to something new, innovative, powerful, bigger than oneself. To seek innovations on materials, techniques of industrialization and uses to impulse a new economic reality. “We want to be part of this transformation related to the respect of our environment, it is for us, essential to work in this respect of men and nature. Men are at the heart of the project with the desire to recruit and form a passionate team, surrounded by experts recognized as the best in their field.

And the innovation doesn’t stop here, because the constructive process makes it possible to envisage fast evolutions from one boat to another while remaining well priced. An ambitious and respectful project ; Welcome to the Windelo adventure.

Dans le cadre de la confection de nouveaux types de catamaran made in Occitanie, un choix audacieux d’innovation écologique a été retenu en partenariat avec le Centre des Matériaux des Mines d’Alès (C2MA – IMT MINES ALES) (Gard). Il s’agit à la fois d’allier performance écologique en termes de minimisation de l’empreinte environnementale et résistance des structures, et ce, dans une démarche globale d’économie circulaire sur l’ensemble des parties du bateau. Pour ce faire, et en lien avec l’IMT MINES ALES, Windelo a misé sur l’utilisation de matières premières secondaires, compétitives des matériaux pétrosourcés vierges, et parfaitement conformes au cahier des charges sur le plan des performances mécaniques. C’est un réel premier pas vers l’élaboration d’une flotte de navires 2.0 s’intégrant complètement dans les enjeux et défis écologiques du XXIème siècle.

Associées à une démarche écologique d’économie circulaire intégrant une part non négligeable de matières premières secondaires concurrentielles des matières vierges, l’architecture de conception et la résistance des matériaux des nouveaux catamarans de Windelo sont éprouvées par des tests mécaniques réalisés au Centre des Matériaux des Mines d’Alès (C2MA – IMT MINES ALES) (Gard) en lien avec les architectes et designers du projet. La conception du navire, et en particulier les bordées et étraves, passe par une recherche de structuration performante de l’agencement des matériaux le composant, combinée à une géométrie d’assemblage optimisée sur le plan mécanique. Pour ce faire, des développements d’essais spécifiques, comme l’étude de la déformation de la structure des panneaux constituant la coque du navire, sont étudiés par des techniques de corrélation d’image numériques couplés à des essais de résistance mécanique normalisés.

La rencontre avec Olivier et Gautier a été une agréable surprise pour moi, dès l’exposé de leur projet, j’ai vu réunis tous les ingrédients d’une réussite, l’expérience de gestion d’entreprises mais avec une modestie rassurante, le souci de former une équipe des meilleurs experts (sourire) et une réelle écoute de leurs avis. Au fil des rencontres, les discussions ont ravivé mes souvenirs de la création puis du développement de Catana. Les mêmes motivations, la même recherche de perfection, la même audace teintée de modestie que nous avions au départ du projet. Windelo est centrée sur le produit ; une ligne de catamarans performants construits avec les techniques les plus modernes. Je n’en avais pas conscience à l’époque mais je crois que le succès d’un bon bateau vient de cette passion pour la mer avec la volonté de marier confort sécurité et performance. Je retrouve ici cette passion, et aujourd’hui ce qui a fini de me conquérir c’est le souci de préservation de la nature, tant dans les matériaux choisis que dans les méthodes de production.

Le programme de grande croisière auquel se destine ce nouveau bateau pose la question de l’antagonisme entre d’une part la recherche de performances sous voiles et du plaisir de navigation, et d’autre part l’aménagement d’espaces de vie agréables et généreux. L’originalité de la réponse apportée ici réside dans la disposition du cockpit rassemblant poste de barre et manœuvres au centre du bateau et dans le traitement de l’espace de vie qui occupe l’arrière de la nacelle. Juste en arrière du mât le cockpit extérieur offre deux postes de barre protégés du vent et des embruns, une belle vue sur les voiles et sur les étraves, et permet d’avoir l’ensemble des manœuvres à portée de main tout en limitant les besoins de circuler sur le pont. Hors navigation, le cockpit peut être plus largement protégé de l’extérieur et s’ouvrir sur l’espace arrière. De plein pied en arrière de ce cockpit, nous n’avons pas aménagé deux espaces de vie dupliqués l’un à l’intérieur et l’autre à l’extérieur mais un seul grand espace dont le degré d’ouverture est très largement modulable. Nous avons porté notre effort sur la géométrie des limites matérielles et visuelles de cet espace et sur les cinématiques d’ouverture des baies. Une fois ouvertes elles « disparaissent » pour transformer l’intérieur en extérieur. La générosité des ouvrants permet également de moduler la ventilation de cet espace en jouant sur une large gamme d’ouverture sur ses quatre côtés Ce travail sur la modularité et sur la disparition des limites se retrouve à l’extrême arrière de la nacelle, avec une plateforme articulée aux bossoirs se transformant en plancher au mouillage, et dans les cabines arrières dont le large hublot tournant fait « sauter » l’angle entre bordé latéral et face arrière. L’espace de cabine est donc généreux malgré la relative étroitesse des coques. L’ensemble de ces choix nous permet de conjuguer une emprise contenue de la nacelle, gage de maîtrise du devis de poids, à un espace à vivre généreux, avec une place centrale accordée à la navigation et aux manœuvres. L’élancement des pointes avant, l’importante hauteur libre sous nacelle, et l’attention portée au centrage des masses, complètent les qualités marines attendues pour un programme de navigation hauturière. L’autre originalité du projet apportée par ce nouveau chantier se trouve dans l’approche d’« éco-conception » portant sur les matériaux et le mode constructif. Limitant fortement le recours aux moules ce dernier apporte une plus grande marge de liberté dans les déclinaisons et évolutions des bateaux ainsi conçus.

Qui sait lequel du père ou du fils est le plus passionné ? Peu importe. L’important ici est d’écrire un projet innovant au sein d’une culture familiale, pour aujourd’hui et les générations à venir. Passer le flambeau, le relais ; c’est la volonté d’Olivier Kauffmann. « Au début je voulais me faire mon propre bateau, pour ma famille et moi ; partir faire un tour du monde sur un catamaran performant et plaisant à vivre. Je rêvais à une qualité d’espace inédite. Aujourd’hui, l’envie a mûrit, et je tiens à le partager avec la grande famille des marins ».

Windelo c’est l’envie de s’exposer à quelque chose de nouveau, d’innovant, de performant, de plus grand que soi. Aller chercher des innovations sur des matériaux, des techniques d’industrialisation, des usages et impulser une nouvelle réalité économique. « Nous voulons faire partie de cette transformation liée au respect de notre environnement, c’est pour nous indispensable d’œuvrer dans ce respect des hommes et de la nature. Les hommes sont au cœur du projet avec la volonté de recruter et former une équipe de passionnés, entourés d’experts reconnus comme les meilleurs dans leur domaine ».

Et l’innovation ne s’arrête pas là, car le process constructif permet d’envisager des évolutions rapides d’un bateau à un autre tout en restant bien placé en prix. Projet ambitieux et respectueux, bienvenu(e) dans l’aventure Windelo.

- Build Your Antares 44 Hybrid

- Build Your Antares 44 GT

- Antares Hybrid Details

- Optional Salon Layout

- GT and Hybrid Overview

- Hybrid Design

- Standard Features

- Specifications & Layout

- Performance

- Building the Antares

- Antares Design Concepts

- Electrical Systems

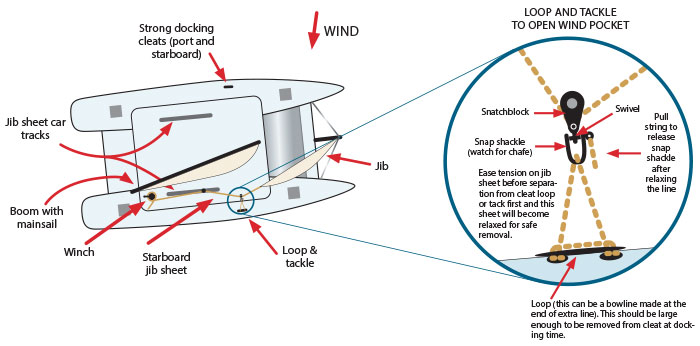

- Antares Line Management

- Ted Clements – The Legend

- Antares Owner Roundtables

- Owner Satisfaction Survey

- Antares University

- Owner Adventures

- Interior Photos

- Exterior Photos

- Featured Videos

Antares doesn’t cut corners by installing sail-drives.

The following key advantages of shaft drive propulsion for a global cruising yacht are an important decision factor for anyone considering such a voyage., low maintenance, easily serviced, best handling under power, balanced boat, watch this video if you are still unsure how hard it is to service a sail-drive, especially in remote places around the world., example photos of sail-drive maintenance.

Automated page speed optimizations for fast site performance

JavaScript functionality for your browser has been deactivate. Please activate JavaScript so you can use all functions on this page.

- ‹ Return |

- › Products

- › Hybrid Drives

Deep Blue Hybrid

Deep blue is a fully integrated propulsion and energy management system, industrially engineered and customizable with modular components. the result is exceptional performance, compliance with international safety standards, and highly intuitive operability.

- Relaxation: no noise from the motor and only a little noise from the generator

- Environmental protection: use renewable forms of energy

- Independence: adequate energy on board, less need to head for a marina

- Convenience: simple joystick docking

- Simplicity: only one type of fuel – and less of it required

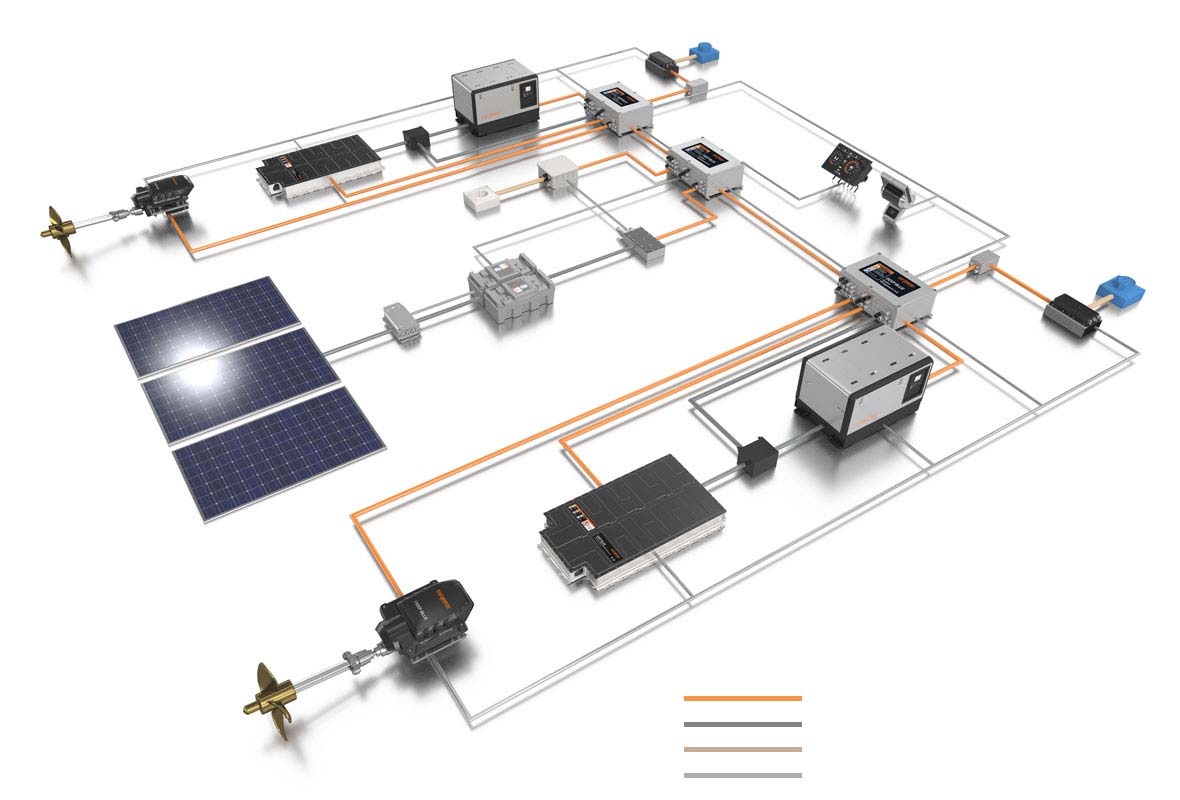

System Overview of the Hybrid Drive System

System Components

High-capacity lithium battery technology.

Lithium-based batteries are the technology of choice for electric mobility applications. They store significantly more energy than all other batteries, they maintain a high current, they do not lose their charging capacity, they supply power reliably, and have no memory effect. They also have a much longer useful life than lead-based batteries.

The benefits for customers:

• High energy density

• Lower costs

• Long service life

• Highest quality and safety standards

Dimensions and preliminary specifications

Click here to learn more about battery technology

Economical auxiliary power

Third-party generators can be integrated into the Deep Blue system via the DC generator interface developed by Torqeedo. The converter generators eliminate the fixed ratio between rotational speed, power and voltage output.

Integrated into the information, safety and energy management system of the Deep Blue Hybrid, the generators produce any combination of power and voltage as required, adopted to individual setting.

Third-party generators can be integrated into the Deep Blue system via the DC generator interface developed by Torqeedo, providing long-range motoring and efficient backup power for serial hybrid systems. The converter generators eliminate the fixed ratio between rotational speed, power and voltage output.

Integrated into the information, safety and energy management system of the Deep Blue Hybrid, the generators produce any combination of power and voltage as required, adopted to individual setttings.

Technical Data

Typical application areas

Perfect for ...

• Torqeedo Deep Blue Hybrid drives with shaft power from 25 to 100 kW (equivalent to 40 – 160 HP)

• Sailing yachts, ferries, water taxis, etc., with hull lengths from 40 to 110 feet (12 – 33 m)

Highly flexible thanks to four operating modes

The Deep Blue Advanced Energy Management System offers four ways of conveniently operating the hybrid system automatically:

Electrical drive power, on-board power and charging power of the highest standard

The Advanced Hybrid Control System for the Torqeedo Deep Blue Hybrid system controls the generator to optimum effect (single or twin installations). It provides a reliable supply of electricity for 360V DC boat drive systems as well as all other 110/230V AC and 24V DC power supply systems on board:

Hybrid and charging power for the Torqeedo Deep Blue system

• AC on-board power supply for galley, air conditioning, water maker and other electrical consumers on board (hotel loads)

• Low-voltage DC power for lighting, radio, navigation, winches, etc.

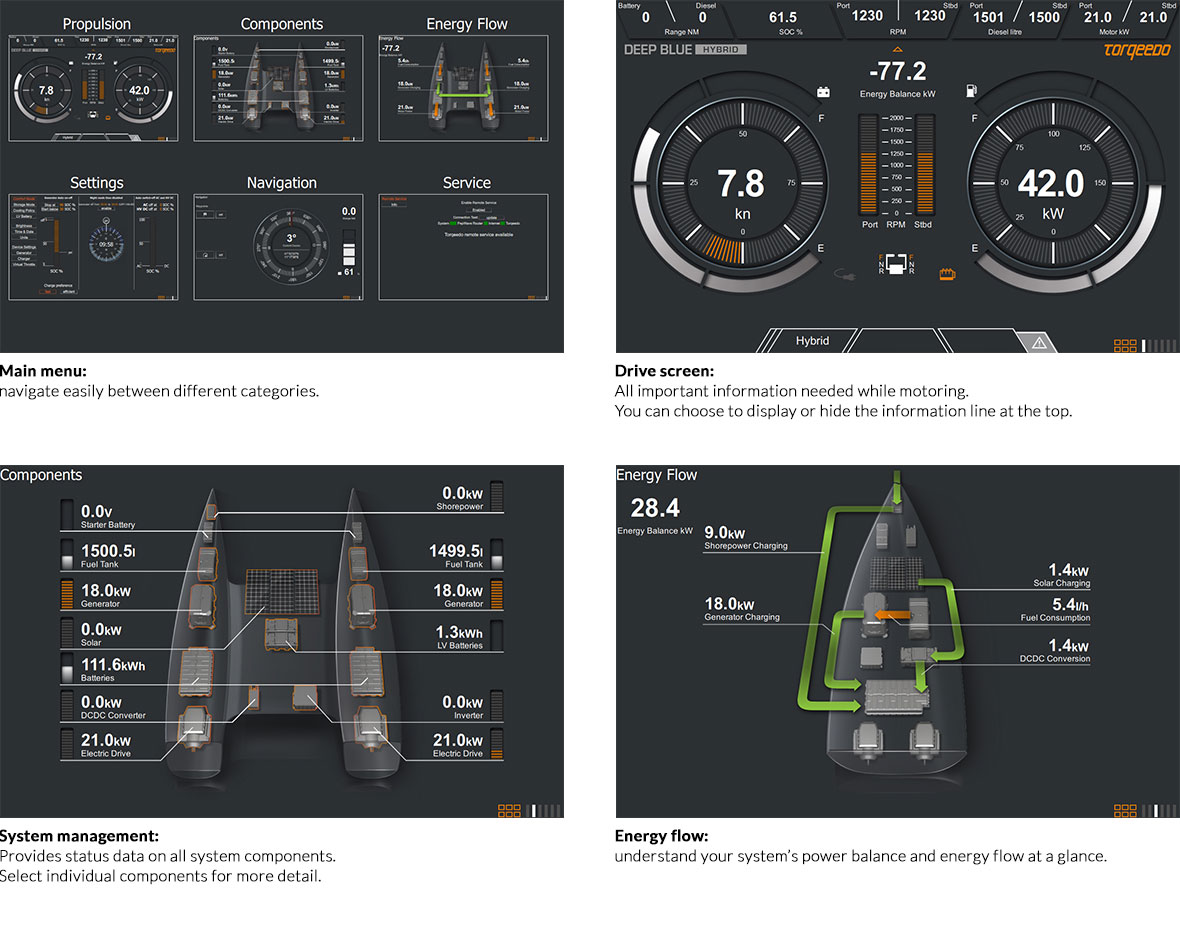

Always in control

Deep Blue Hybrid offers intuitive operation presented on the multifunctional display, providing a complete overview of the entire system and access to all control functions.

The software keeps an eye on everything and prevents errors like deep-discharging batteries. An easy-to-understand graphical user interface is available as either multihull or monohull and delivers complete, up-tothe- minute system visualisation.

Premium throttles

We’ve come to expect an intuitive way to operate our technical devices. We expect detailed information, nicely displayed and clearly arranged. We expect that the objects we use are both beautiful and functional.

This is what spurred us to create the new Torqeedo throttle family and improved user interface for Deep Blue.

Our premium throttles offer the right solution for every application, whether for sailboats or on motorboats – ergonomic, strong and functional. All premium throttles come with Bluetooth built in for simple integration of Torqeedo’s TorqTrac smartphone app.

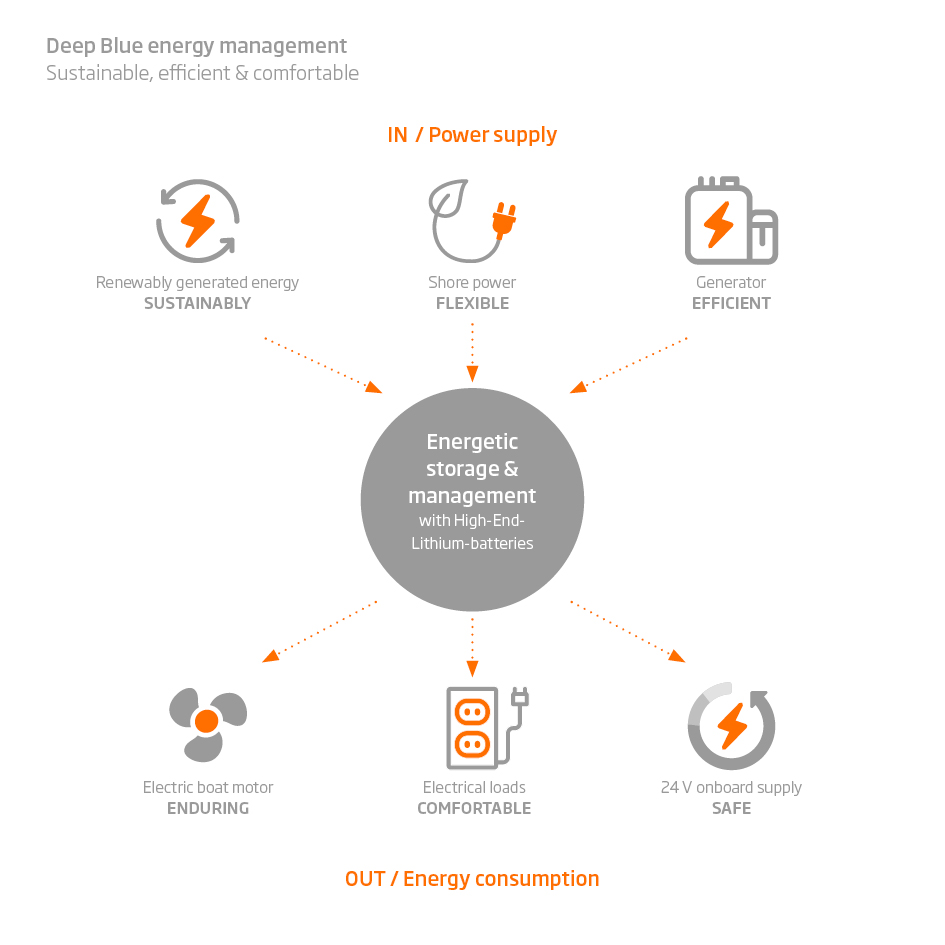

Hybrid Drive System and Integrated Energy Management

Hybrid drive system.

Powerful and silent electric drive systems allow manoeuvring and sailing at hull speed.

High-performance batteries adapted from the automotive industry enable prolonged motor-cruising for up to 50+ nautical miles without use of a generator. Solar power generated on board and hydro-generated energy – the propeller rotates while boat is under sail – provide additional propulsion. Besides, the integrated generator provides sufficient energy to cover long distances, if required.

The slowly rotating electric drives allow precise maneuvering and in combination with joystick docking makes putting out to sea and berthing as easy as pie.

Integrated energy management

The integrated management system of Deep Blue Hybrid makes it possible to use available power in any way you wish – for the powerful high-voltage drive system, for the 24 V on-board power supply or to operate equipment with 230 V AC current. Deep Blue Hybrid is designed in such a way that energy is always available where it's needed.

The combination of energy generated from renewable sources and by the generator means that there is always sufficient power available. However, the generator does not need to run for as long.

Clean and safe electricity can be used for all equipment and so it is no longer necessary to have propane or petrol on board. A tender can also be run electrically and can be charged from the Deep Blue Hybrid on-board power system.

Professional Safety

Professional safety for your sailing yacht.

Particular attention should be paid to standards compliance and safety during the development of a hybrid drive system. During the years spent on developing the Deep Blue Hybrid system we followed safety concepts that, for example, are standard in the automotive industry – but which previously could not be found in powerful electric drive systems for electric sailing yachts.

In addition, electrical drive systems for electric sailing yachts pose special challenges that are not relevant for other industries. In this respect, it is not enough to just follow the standard of other industries for high-voltage boat drives. As we are used to setting new standards, we have done so with regard to safety. Below you will find a number of examples of the Deep Blue Hybrid's unique safety concept.

Isolation monitor: constantly monitors that the voltage from all 360 V components is completely isolated from the boat – not just for individual system components but for all of them. If damage is detected, e.g. to the cable insulation, the system will issue an alert. In the event of dangerous insulation failure, the system will be shut down.

All components are waterproof: Components that were not specifically developed for boats are not always waterproof. All the components of a high-power system on a boat must be waterproof to guarantee safe operation. That is why all of our components are waterproofed.

Automotive industry-level battery safety: The first lithium batteries for the marine industry with the advanced quality standards of the automotive sector are the result of Torqeedo's collaboration with established battery manufacturers. Integrating a battery into a drive system and the associated safety concept alone requires considerable effort that can only be achieved by working together with the battery manufacturer.

Battery venting: In the unlikely event that the redundant safety mechanisms of the battery fail, the battery cells can reduce their temperature and pressure via a pressure valve. While batteries are installed in electric cars in such a way that they can discharge battery gases directly onto the road, on electric boats the gases must be channelled safely off the vessel. We developed the first safe venting system for boats for the Deep Blue System.

Battery damping: All components on fast and seagoing boats are subject to constant high levels of shock that exceed shock levels on the road – in some cases over 12 g of acceleration force. The same holds true when trailering the boat. Since batteries and battery electronics are not designed for these constant impacts, they need their own damping system on boats (in addition to the damping mechanisms within the battery). Torqeedo is the only company in the world that provides this for maritime use.

Benefits for Boatbuilders

Custom-built solutions are often pursued in order to meet a user's requirements. These individual hybrid projects raise a number of difficulties:

- High-end components do not exist for the custom project. High-tech safe lithium batteries, for example, require an intensive design-in process in close cooperation with the battery manufacturer's research and development department. However, reputable high-voltage battery manufacturers do not supply their batteries for custom solutions that they are not familiar with and that have not been coordinated with them in detail.

- Creating an integrated hybrid system requires a comprehensive research and development project accompanied by many person-years in the field of development running to the tune of several million euros. These efforts are not undertaken for custom projects, leading to lower reliability and a lack of complex but important safety features (such as pilot lines).

- The system integrator has the statutory duty to ensure that the hybrid system complies with all the relevant and mandatory standards such as the Machinery Directive and the EMC Directive. Custom hybrid systems do not generally meet these standards. Since a boatbuilder is responsible for ensuring that the entire boat complies with standards, the installation of custom-built hybrid systems constitutes a serious risk for boatbuilders.

Unlike custom-built hybrid systems, DEEP BLUE HYBRID addresses the requirements of environmentally aware customers, offering a turnkey solution that guarantees compliance with the relevant norms and standards.

- DEEP BLUE HYBRID was created in an extensive research and development project involving a large number of mechanical and electrical engineers over several years. The components were carefully selected and coordinated with an overall system. Essential inspections and certifications were performed at system level.

- High-end components such as hybrid batteries from the automotive industry were integrated into the system.

- Torqeedo assumes responsibility for the functionality and compliance with relevant standards for the whole system.

- DEEP BLUE HYBRID was developed on the basis of modular components. It allows flexibility and scalability without affecting system integration and reliability.

- DEEP BLUE HYBRID for electric ferrys, electric sailing yachts, electric catamarans & electric water taxis.

If we have awakened your interest in our products we would be pleased to send you more detailed information. Simply enter your details in the contact form below and we will get in touch with shortly.

Everything electric boats and boating

Electric Saildrive and Pod Boat Motors

Plugboats Guides Motors News Motors For Sale

Welcome to what we believe is the most complete guide to electric saildrive and pod boat motors. It provides top line details for more than 150 individual motors sorted by power range, style and usage. It has been assembled to provide a single place where someone interested in electric marine propulsion can find comparative information for motors made all over the world.

You may also be interested in our other guides »» Guide to Electric Outboards Under 5kW »» Guide to Electric Outboards Over 5kW »» Guide to Electric Inboards »» Guide to Electric Trolling Motors »» Guide to Electric Boat Batteries

»» Plugboats also has the world’s largest and most complete Directories of over 600 elect ric boats, motors, batteries, accessories, solar panels and rental/charter companies

Information on using this Plugboats Guide

The top of this web page is the Illustrated Guide with photos of the motors and specifications to the right.

Sortable/Searchable Table

At the bottom of the page is a table that can be searched if you know you are looking for a certain type of motor (i.e. pod or saildrive), a certain power range, or for a specific weight/length of boat. If you are going to use the table, the page is best viewed on a computer rather than mobile or tablet.

Illustrated Guide

The motors are organized in alphabetical order by manufacturer, then by style of motor, i.e. fixed pod, steerable pod, saildrive and then by power of motor within those listing. For many styles there are multiple powers of motor available and where that is the case we have made it as easy as possible to line up the motor with its specifications. i.e. if there are three power of motor with different weights, it will be noted as kW: 2kw, 2kw, 3kw • Weight: 10kg, 12kg, 15kg. For some manufacturers the variations are more complicated and we have done our best to make it simple and understandable.

There is a lot of variety in the way manufacturers detail the technical attributes of their products. We have tried to take the most common measurements and assemble an ‘apples to apples’ comparison. See the notes below in ‘Measurements’

The photographs and drawings are from the manufacturers’ websites and are not shown in any consistent scale.

kW • Voltage • Current • HP: Not all manufacturers list all of these specifications. We have included the specifications available and where not available have used the notation N/A.

kW is the kW rating provided by the manufacturer. Most websites do not indicate whether it is input or output kW. When it is indicated, we took the output.

Voltage is most often referred on the sites as ‘Voltage’. Some indicate nominal or peak, we have used nominal and indicated if peak is also referenced.

Current Is noted when the manufacturer supplies the information. Generally it is measured in amperes: A. In some cases the manufacturer uses Amp Hours: Ah and we have noted it where that is used.

HP : is ‘HorsePower equivalent’ so that you can get an idea of the power of the motor in comparison to a HP rating you might be more familiar with. Where available, these measurements come from the manufacturer’s website, and different manufacturers measure the HP in different ways. Some even use metric horsepower, which is slightly different from imperial horsepower. Again, we have tried to make it as apples to apples as possible. (For general guidance, 1kW is round one and a third HP 1kW=1.3HP, or the reverse is that 1HP is around three quarters of a kW: 1 HP = .75kW).

Static Thrust. Torque, Efficiency: This is probably the specification that has the most variability. We have simply given whatever information the manufacturer has published on their website, when available.

Range and Running Time : We have not included estimates of range or running time because it depends on too many factors: battery size (sometimes type also), water conditions, speed, etc. The exceptions are for the ePropulsion and Torqeedo models which have batteries from the manufacturers specifically matched to the motors and therefore provide estimates on their websites.

General : If a manufacturer publishes a specification, we have tried to include it here, even tough other manufacturers may not include the same type of measurement.

Information on this page updated February 4, 2024

You may also want to check our Directory of Electric Boat Motor manufacturers, dealers and distributors around the world, or the Plugboats Marketplace of electric boat motors for sale.

Manufacturers in this Buying Guide: Aquamot • Bellmarine • Combi • Electric Yacht • ELECTRINE • EP Technologies • ePropulsion • E-TECH • Fischer Panda • Gardenergy • Kräutler • Navigaflex • Oceanvolt • Piktronik • Rim Drive Technology • Seadrive • TEMA • Torqeedo

Aquamot was founded in 2003 by engineer Siegmund Hammerstrom and has grown to be a leading manufacturer of electric motors and accessories, including outboards inboards, chargers and batteries. They have two lines of fixed pod motors: Trend and Professional, as well as a line of steerable pods that line up with the power ranges of the Professional line.

Aquamot Trend Fixed Pod 1.1FM and 1.6FM

- Recommended Boat Size: <1.8 tons

- kW : 1.1 / 1.6 • Voltage : N/A • Current : N/A • HP : 3.5 / 5 • Static thrust : 89lbs

- Motor Type : Brushless AC asynchronous • Passive water cooled (motor underwater)

- Weight (kg) : 10.2 / 11.3

- Propeller/RPM : 3 blade fixed, folding optional • RPM : N/A

- Other : Includes: Integrated/removable lithium battery (0.64kWh), charger, display, emergency kill switch. Optional: spare battery, customized compensation wedge, folding propeller ($US 835). Warranty: 2 year limited

- Country of Manufacture : Austria

- Price (MSRP) : $US 2,200 / $2,600

Aquamot Trend Fixed Pod 2.2FM and 4.3FM

- Recommended Boat Size: <4 tons kW : 2.2 / 4.3 • Voltage : 24 / 48 • Current : N/A • HP : 6.4 / 11 • Static thrust : 124 lbs / 197 lbs

- Motor Type : Brushless AC asynchronous• Passive water cooled (motor underwater) Weight (kg) : 12.2 / 13.9

- Other : Includes: Controller, display, basic cables, emergency kill switch. Optional: customized compensation wedge, folding propeller ($US 835). Two year limited warranty.

- Price (MSRP) : $US 3,300 / $3,750

Aquamot Trend Fixed Pod 11.0FM to 25.0FM

- Recommended Boat Size: N/A

- kW : 11 – 25 • Voltage : 48 – 96 • Current : N/A • HP : 28 – 45 • Static thrust : n/a

- Motor Type : Brushless AC asynchronous• Passive water cooled (motor underwater)

- Weight (kg) : 44.3 – 48.9

- Propeller/RPM : 3 blade fixed • RPM : N/A

- Other : Includes: Controller, display, basic cables, emergency kill switch. Optional: customized compensation wedge. Warranty: 2 year limited

- Price (MSRP) : $US 7,150 / $9,915

Aquamot Professional Fixed Pod F10e to F250e

- kW : 1 – 25 • Voltage : 24 – 96 • Current : N/A • HP : 45 – 339 • Static thrust : n/a

- Motor Type : Sensor-less AC asynchronous • Passive water cooled (motor underwater) • Efficiency : 92%

- Weight (kg) : 12 – 50

- Propeller/RPM : 2 blade fixed, folding/feathering optional • RPM : N/A

- Other : Integrated anode, permanently usable for salt or fresh water, maintenance free. Operating efficiency 92%, Included: Custom-made compensation wedge, Controller, throttle, battery monitor, cables, Optional: display, folding/feathering propeller. Warranty: 2 year limited

- Price : N/A

Aquamot Trend Steerable Pod UF10e to UF250e

- Other : Optimized cavitation plate. Permanently usable for salt or fresh water, maintenance free. Operating efficiency 92%, Included: Custom-made compensation wedge, Controller, throttle, battery monitor, cables, Optional: display. Warranty: 2 year limited

»» Bellmarine website

Bellmarine is a very well established electric boat motor company with a history going back to 1999. Along the way they merged with a battery accessory manufacturer and have now been purchased by Transfluid, a large scale industrial motor manufacturer. Bellmarine offers a wide range of electric boat motor configurations, with their saildrive system consisting of their own motor combined with Yanmar drive mechanics. They range from 2kW to 20kW in power with either air or liquid cooling. They also offer a regeneration option. You may want to download the full Bellmarine catalogue

Bellmarine SailMaster Air Cooled Models 2A, 5A, 7A, 10A, 15A, 20A Download .pdf brochure

- kW : Bellmarine uses Nominal and Intermittent kW measurements. These are the intermittent figures: 2, 5, 7, 8, 10, 15, 20 • Voltage : 48V except for the 8A, 15A and 20A models which are 96V • Current : N/A • HP : 2.5, 6.5, 9, 10.5, 13, 20, 25

- Motor Type : Permanent Magnet AC • Air cooled

- Weight (kg) : N/A

- Propeller/RPM : propeller not supplied • RPM : Motor: 1500, Propeller 750 except for 20kW which is Motor 3000, Propeller 1500

- Other : Includes Yanmar SD25 Sail drive leg with 2:1 reduction, motor, controller, , stainless steel motor support brackets.

- Country of Manufacture : Netherlands

Bellmarine SailMaster Liquid Cooled Models 3W, 7W, 10W, 15W, 20W Download .pdf brochure

- kW : Bellmarine uses Nominal and Intermittent kW measurements. These are the intermittent figures: 3, 7, 10, 15, 20 • Voltage : 48V: for all models except 8A, 15A and 20A – 96V: Models 8A, 15A, 20A • Current : N/A • HP : 4, 9, 13, 20, 25

- Motor Type : Permanent Magnet AC • Liquid cooled

- RPM : 1500: Models 2A, 5A, 7A, 8A, 10A, 15A – 3000: Model 20A

»» Combi website

Combi Outboards was founded in 1979 in Giethoorn (‘the Dutch Venice’) to supply rental boats with clean electric power. It is now a leading international supplier of electric propulsion solutions for the maritime market. Combi manufactures inboards, pods, hybrids and outboards. There are six pods ranging in power from 1kW to 3.5 kW: 1, 1.5, 2, 2.5, 3 and 3.5kW. They are available both as fixed pod or steerable pods.

Combi Nautic Fixed Pod/Saildrive Download .pdf brochure

- kW : 1.0 – 3.5 • Voltage : 24 (1.0kW + 1.5kW), 48 (2.0kW – 3.5kW) • Current : 42A – 73A • HP : 4 – 9

- Motor Type : Asynchronous AC • passive water cooled Weight (kg) : N/A

- Propeller/RPM : 3 blade fixed – 220mm or 230mm • RPM : 1050 (3.5kW 1300) Other : “Easy Connect” system delivered Plug & Play for owner installation.

Combi Nautic Steerable Pod Download .pdf brochure

The Steerable Pod Nautic models have the same specifications as the Saildrive models above.

- Motor Type : Asynchronous AC • passive water cooled

- Propeller/RPM : 3 blade fixed – 220mm or 230mm • RPM : 1050 (3.5kW 1300)

- Other : “Easy Connect” system delivered Plug & Play for owner installation.

Electric Yacht

Electric Yacht is one of the premier US suppliers of saildrives. They have developed a Plug-n-Play system that has been engineered for quick, simplified installation as well as long term durability. Their systems offer regenerative power while under the sail. 10 years of proven production with over 450 installs. 3 Year Warranty

Electric Yacht QuietTorque™ 10.0 Sail Drive

- Recommended Boat Size: <6 tons – 34’ (10m)

- kW : 10 • Voltage : 48 • Current : 200A • HP : 10.5

- Motor Type : Brushless PMAC

- Weight (kg) : 45

- Propeller/RPM : 2 or 3 blade, fixed or folding, 12” – 16” • RPM : N/A

- Other : Installs through 9” hole, Anodized aluminum frame and waterproof throttle,Digital Display of: State of Charge (SOC, Voltage, Current, Power, Motor RPM, time to discharge based on current power consumption, updated in real time, Programmable regeneration. 3 Year Warranty.

- Country of Manufacture : USA

- Price (MSRP): $US 11,995

Electric Yacht QuietTorque™ 20.0 Sail Drive

The Electric Yacht Quiet Torque 20 is essentially the 10.0 with twin motors

- Recommended Boat Size: <12 tons – 45’ (14m), catamarans 40’-46’ (12-15m)

- kW : 20 • Voltage : 48 • Current : 400A • HP : 21

- Motor Type : Brushless PMAC X 2

- Weight (kg) : 77 Propeller/RPM : 2 or 3 blade, fixed or folding, 12” – 18” • RPM : N/A

- Other : Installs through 9” hole, Anodized aluminum frame and waterproof throttle,Digital Display of: State of Charge (SOC, Voltage, Current, Power, Motor RPM, time to discharge based on current power consumption, updated in real time, Programmable regeneration. 3 Year

- Warranty.

- Price (MSRP): $US 14,695

Also: Electric Yacht QuietTorque™ 30.0 Sail Drive (boats <14 tons) Electric Yacht QuietTorque™ LC 45 Sail Drive (boats <17 tons) Electric Yacht QuietTorque™ LC 60.0 Sail Drive (boats <22 tons)

- Recommended Boat Size: 14 tons – 22 tons, 45’- 60′ (15-18m)

- kW : 30 – 60 • Voltage : 48 – 96 • Current : 300Ah – 600Ah • HP : 48 – 65

- Motor Type : Brushless PMAC X 2 • liquid cooled

- Weight (kg) : 100 – 106

- Propeller/RPM : N/A

- Other : Installs through 9” hole, Anodized aluminum frame and waterproof throttle, Digital Display of: State of Charge (SOC, Voltage, Current, Power, Motor RPM, time to discharge based on current power consumption, updated in real time, Programmable regeneration. 3 Year Warranty.

- Price (MSRP): $US 19,995 – 23,495

»» ELECTRINE website

ELECTRINE is a Korean manufacturer which has focused on maritime electrification since 2010, when the idea of electric mobility was still relatively uncommon. The company was known as LGM until 2020 and has had a consistent R&D effort for many years. They manufacture electric outboards, inboards and saildrives as well as accessories and Lithium-ion batteries using a Carbon Nano Tube heat exchanger technology. Ther are 6 motors in their eSaildrive line, ranging from 8 kW to 110 kW.

ELECTRINE eSaildrive line: S-8, S-16, S-25 (shown), S-40, S-80, S-110

- Recommended Boat Size: Daysailer / Racing / Monohull /Multihull

- kW : (Max) 8, 16, 25, 40, 90, 110 • Voltage (Vdc): 48, 48, 96, 96, 345.6, 345.6

- Motor Type : N/A

- Weight (kg) : 40.5, 46.5, 50.5, 172, 198, 218

- Other : Hydrogeneration on 8kW and 16kW models. ELECTRINE also makes batteries customized for the motors

- Country of Manufacture : Korea

- Price (MSRP): N/A

EP Technologies

»» ep technologies website.

EPTechnologies is a complete marine propulsion provider for electric and hybrid vessels. The company specializes in custom electric and hybrid systems, but also has ‘off the shelf’ motors, including a range of saildrives. Their Electric Turnable Saildrive offers 360-degree rotation, the key advantage being that no additional thruster is required behind the boat. Other saildrives (SD-25, SD-60, SD-15) have a fixed lower unit. All saildrives are include a complete system utilizing batteries designed and built by EP Technologies.

EP Technologies Turnable Saildrive

- kW : 25 – 60

- Voltage (VDC): 100 – 800

- RPM : 500 – 2000

- Other : 360° Rotatable, Electric servo motor, Joystick Control

- Country of Manufacture : Denmark

- Price : Contact EP Technologies

EP Technologies Saildrives: SD-25, SD-50, SD-15

- kW : SD-25: SD-60: 25, 39, 60, SD-15: 65, 95

- Voltage (VDC): SD-25: 48, SD-60: 100 – 800, SD-15: 400 – 800

- RPM : SD-25: 1000 – 2000, SD-60: 500 – 2000, SD-15: 500 – 2000

ePropulsion

»» epropulsion website.

ePropulsion was founded in 2012 by three engineers from the Hong Kong University of Science and Technology (HKUST). The company continues to have a strong engineering culture where each engineer is individually responsible for creating as much value for users as possible. ePropulsion offer two pod models based on their outboards: the 1kW Spirit and 3kW Navy.

Click here to view motors from ePropulsion dealers in the Plugboats Marketplace

ePropulsion Pod Drive Evo 1.0 , 3.0, 6.0

- kW : 1, 3, 6 • Voltage : 40.7, 48 • Current : 25A, 62.5A • HP : 3, 6, 9.9 Static Thrust : 71, 132.6

- Weight (kg) : (Including integrated battery) 14.1, 15.6

- Propeller/RPM : Spirit: 2 blade, 28 × 14.7 cm (11′ × 5.8″), Navy: 2 blade, 26 × 17.1 cm (10.2″ × 6.7″), RPM: Spirit 1200, Navy 2300

- Other : Hydrogeneration, Includes battery and wireless remote controller (cable option also), Spirit has 1.1 kWh lithium battery, Navy has 3.0 kWh

- Country of Manufacture : Hong Kong/China

»» E-TECH website

E-TECH is a subsidiary of boatbuilder Starboats that was started in 2008 because they were dissatisfied with other electric motor offerings in the market at the time. The company has developed fixed pods, steerable pods and outboard motors that all utilize an in-water BLDC (BrushLess DC permanent magnet) pod motor in a watertight aluminum casing. There are 5 pod models available in both fixed pod and steerable pod configuration. All of these are equipped with the ruddershaft, tube and steering lever. There are also 4 models of high torque pods available only in fixed pod format.

Click here to view motors from E-TECH dealers in the Plugboats Marketplace

E-TECH 4 POD, 7 POD, 10 POD, 15 POD, 20 POD Link to Fixed Pod Motors • Link to Steerable Pod Motors Download .pdf brochure

- kW : 4.3, 7.5, 10.9, 16.6, 19.5 • Voltage : 48, 48, 48, 72, 96 • HP : ≈ 6, 10, 15, 22, 27 • RPM : 1350, 1350, 1470, 2240, 2200

- Motor Type : Brushless PMDC • water cooled

- Other : Includes controller, display with battery monitor, joystick (side- or top mounting), 2m steering cable, 5m connecting cables between controller and steering position (standard 5 meter).

- Country of Manufacture : Poland

The four High Torque E-TECH PODH engines are designed for those applications where a very high torque is needed.

E-Tech High Torque PODH: 13 POD, 18 POD, 23 POD, 35 POD Download .pdf brochure

- kW : 11.9, 16.7, 21.5, 33.7 • Voltage : 48, 72, 96, 144 • HP : ≈ 16, 23, 29, 45 • RPM : 760, 1140, 1520, 2500

Fischer Panda

»» Fischer Panda

Fischer Panda is one of the world’s best known manufacturers of marine generators but are also manufacturers of high quality electric boat motors, sometimes marketed under the ‘Whisperprop’ name. They have an “EasyBox” system that is intended to take the guesswork and complication out of purchasing electric boat motors.

Fischer Panda 48V Underwater Drive System (Easybox) Download .pdf brochure

- kW : 3.8 – 20.0 • Voltage : 48 • Current : N/A • HP : 5 – 25

- Motor Type : Brushless Permanent Magnet (PMAC)

- Weight (kg) : 18.7 – 120

- Propeller/RPM/Torque : Propeller not included • RPM : 600 – 2500 Torque (nM) : 28 – 320

- Other : Includes: Fischer Panda EasyBox control unit, control panel, throttle Options: Propeller, propeller protector, battery bank, charger, shore power connection.

- Country of Manufacture : Germany

Fischer Panda EasyBox HV High Voltage System Fischer Panda Download Centre

- Recommended Boat Size: <40 tons

- kW : 50, 80, 100 • Voltage : 360 – 420 • Current : N/A • HP : 65 – 125

- Weight (kg) : 42

- Propeller/RPM/Torque : 5 blade fixed • RPM : 1200 / 1900 Torque (nM) : 398 – 400

- Other : These motors are generally designed for use by small public transportation ferries, commercial working vessels and privately owned leisure yachts. Systems should be customized.

»» Gardenergyy website

Gardenergy is an Italian company established to offer ‘a simple and reliable product featuring cutting-edge technology’. They use the same motors in a variety of ways, cleverly configuring them for outboard, inboard shaft drives, and either fixed pods or steerable pods.

Gardenergy Pod

To see options and download .pdf brochures, go the Gardenergy site and click on ‘Links’. A pop up will appear with options. There is also an option for price list and a Configurator which can help with system assembly and pricing.

There are five Gardenergy pods with power input of: 2kW, 4.3 kw, 6kW, 8kw, 10kW. They are available as fixed or steerable pods.

- kW : 2, 4.3, 6, 8, 10 • Voltage : 48 except for 2kW which is 24V • Current : N/A • HP : 2.5, 5.5, 7.5, 10, 13

- Motor Type : PMAC

- Propeller/RPM/Torque : 3 blade fixed, folding available • RPM : 2kW: N/A, 4.3kW: 1450, 6kw: 1600, 8kW: 1750, 10kW: 1950

- Country of Manufacture : Italy

- Price (MSRP): Download MSRP Price List $US 3,975 – 6,625

»» Kräutler website

Kräutler is a long-established Austrian manufacturer of industrial electric motors. They began construction of electric boat motors in the 80’s mainly because they could not find a product that would live up to the standards of founder Oswald Kräutler. They make motors for industrial and ship use as well as recreational boats and probably offer the widest range of sailpods and saildrives on this page with everything from small .5kW steerable pods to electrically rotatable saildrives with power up to 30kW.

An explanation about the Kräutler section of this guide: The Kräutler fixed pods are available with AC motors (ACV) or DC motors (GPV). The AC are for smaller boats. They also come in two different configurations: fixed propeller and folding propeller. In the interests of making this page shorter, we have divided them in to the motor types for the written descriptions but have shown you the fixed and folding options in the images. In the table each of the motors has a separate listing. NOTE: The GPV motors are only suitable for short use in salt water.

Krautler Submersible Flange Motor Pods with D C motors Download .pdf brochure

- MOTOR TYPE: GPV

- Recommended Boat Size: <1.9 tons

- kW : 0.5, 0.8, 1.6, 2.2 • Voltage : 24 except for 2.2kW which is 36V • Current : 21, 34, 67, 61 • HP : 0.5, 1.0, 1.8, 2.5

- Motor Type : GPV: DC motor with permanent magnets, continuous control

- Weight (kg) : 14, 15, 20, 20

- Propeller/RPM/Torque : 3 blade fixed or folding (see intro note above) • RPM : N/A • Torque : N/A

- Other : ATTENTION: GP motors are only suitable for short use in salt water. Includes: Motor, bracket, electric regulation system, throttle, status display monitor, battery monitor, cables, battery master switcher & fuse, propeller, anode. Operating efficiency 85%

- Price (MSRP):

Krautler Submersible Flange Motor Pods with AC Motors Download .pdf brochure

- MOTOR TYPE: ACV

- Recommended Boat Size: <10 tons

- kW : 1.8, 2.0, 4, 8, 10 • Voltage : 24 (1.8, 2.0kW) 48 (4, 8, 10kw) • Current : 100, 107, 104, 202, 250 • HP : 2.3, 2.5, 5, 10, 13

- Motor Type : ACV: AC brushless three phase asynchronous motor

- Weight (kg) : 21, 29, 29, 40, 50

- Other : Includes: Motor, bracket, electric regulation system, throttle, status display monitor, battery monitor, cables, battery master switcher & fuse, propeller, anode. Operating efficiency 75% – 83%

Krautler Submersible Pod with Tiller Handle Download .pdf brochure

- MOTOR TYPE: ACV or GP

- Recommended Boat Size: Sailboat: <10 tons, Powerboat: <6 tons

- kW : 0.5 – 10 • Voltage : 24, 48 • Current : 21 – 250 • HP : 0.5 – 13

- Motor Type : ACV: AC brushless three phase asynchronous motor • GP: permanent magnet with continuous control

- Weight (kg) : 15 – 54

- Propeller/RPM/Torque : 3 blade fixed • RPM : N/A • Torque : N/A

- Other : Includes: Motor, bracket, electric regulation system, throttle, status display monitor, battery monitor, cables, battery master switcher & fuse, propeller, anode. Tubes/diaphragms available for installation. Standard shaft length: 450mm. Operating efficiency 75% – 85%

Krautler Saildrive Compact Download .pdf brochure

- Recommended Boat Size: <4 tons

- kW : 2.0, 3.0, 4.0 • Voltage : 24, 36, 48 • Current : 104, 100, 99 – 250 • HP : 0.5 – 13

- Motor Type : AC brushless three phase asynchronous motor with continuous control

- Weight (kg) : 42, 42, 42,

- Propeller/RPM/Torque : Propeller not included • RPM : N/A • Torque : N/A

- Other : ATTENTION: SDK drives are only suitable for short use in salt water. Includes: Motor, saildrive gear, base plate for lamination (depending on motor size), electric regulation system, throttle, status display monitor, battery monitor, cables, battery master switcher & fuse. Operating efficiency 80%, 83%, 84%

Krautler Saildrive Fixed Download .pdf brochure

- Recommended Boat Size: Sailboat: <30 tons, Powerboat <12 tons

- kW : 2.5 – 30.0 • Voltage : 24 – 144 • Current : 104 – 370 • HP : 3.5 – 40

- Motor Type : AC brushless three phase asynchronous motor with continuous control. MOTORS 15.0 – 30.0kW are water cooled.

- Weight (kg) : 45 – 91

- Other : ATTENTION: Water cooled drives are only useable in seawater with 2-circle water cooling. ATTENTION: SDK drives are only suitable for short use in salt water. Includes: Motor, saildrive gear, base plate for lamination (depending on motor size), electric regulation system, throttle, status display monitor, battery monitor, cables, battery master switcher & fuse. Operating efficiency 85% – 88%

Krautler Saildrive Mechanical Rotatable: 2 x 45° Download .pdf brochure

All of the Krautler motors with specs shown in the fixed saildrives above can be installed with a mechanical rotatable option shown here or electric rotatable option shown below. The Sail-Drive is supplied with a fiberglass foundation base, which can be laminated to the hull (depending on motor size). For existing Volvo and Yanmar foundations the Sail-Drive is equipped with an adapter plate and can be screwed directly on the existing foundation.

Krautler Saildrive Electric Rotable: 2 x 90° or 360° Download .pdf brochure

All of the Krautler motors with specs shown in the fixed saildrives above can be installed with an electric rotatable option shown here. The Sail-Drive is supplied with a fiberglass foundation base, which can be laminated to the hull (depending on motor size). For existing Volvo and Yanmar foundations the Sail-Drive is equipped with an adapter plate and can be screwed directly on the existing foundation. The electrical rotating mechanism includes an actuating drive with gearbox, electric regulation system for the drive, a steering lever and display.monitor indicating propeller position

»» Navigaflex website

The innovative Navigaflex motor has a Patent Pending design in which the motor itself retracts and pivots and can attached to the boat as an outboard or inboard motor. The motor is made with a minimum of parts, a light construction and is adaptable to all boat hulls. The standard motor can also be ordered with a “booster” to double the power for up to 2 minutes.

Navigaflex Motor

- Recommended Boat Size: 2 tons / 8m – 16 tons / 18m kW : 6kW, 8kW, 10kw, 15KW • Voltage : 48 (nominal) • HP : 8, 11, 13.5, 20

- Motor Type : Brushless Permanent Magnet (PMAC) • Water cooled (10kW and 15KW)

- Weight (kg) : 54 (4KW) – 68 (15KW)

- Propeller/RPM : 2 blade fixed • RPM : N/A

- Other : Retractable motor, Option to regenerate the current under sails, Digital motor controller with touch screen and mobile phone connected remotely.

- Country of Manufacture : Switzerland

- Price : $US 8,000 – 16,000

»» Oceanvolt website

Oceanvolt is one of the best known names in saildrives and its ServoProp regenerating system is regarded as one of the first and best. It is difficult to provide full information about their systems because their website encourages customers to provide information for customized solutions. These are some basics

Click »» here to see Oceanvolt motors for sale from vendors in the Plugboats Market

Oceanvolt SD Saildrive See more detailed information

- Recommended Boat Size: < 80 ft / 25m

- kW : 6, 8, 10, 15 • Voltage : 48 • HP : 8, 11, 13.5, 20

- Motor Type : Synchronous permanent magnet • Closed circulation liquid cooling provides cooling and lubrication

- Weight (kg) : 42.5, 42., 46.5, 46.5

- Propeller/RPM : Propeller not included • RPM : 2200 • Gear Reduction Ratio : 1.93: 1

- Other : Includes: Battery communication kit, hydrogeneration feature • Sold separately: Batteries, Charger, Propeller • Sail Drive with 1.93:1 reduction. Closed circulation liquid cooling provides cooling and lubrication. 10kW and 15kW systems include 15.2kWh Li-ion battery bank, charger

- Country of Manufacture : Finland

- Price : $US 13,500 – 45,000

Oceanvolt Servoprop Saildrive

The Oceanvolt ServoProp is a patented variable pitch sail drive that ‘combines a high efficiency sail drive with the most powerful hydro generator on the market’. Unique feature is the possibility to turn the propeller blades more than 180 degrees. The software controlled variable pitch sail drive adjusts the pitch of the propeller blades automatically so that the power generation and power output are optimal. The blades are designed to give the system maximum efficiency in forward, reverse and regeneration. With the blades set to the neutral sailing position, the propeller creates extremely low drag similar to the drag of a feathering propeller. ServoProp is capable of generating more than 1 kW at 7-8 knots & 3 kW at 11-12 knots.

»» Piktronik website

Piktronik is an Austrian-Slovenian company working on the research, development and production of components for electrical vehicles (EV) and boats. Their pods are available in a variety of configurations that vary by the power output. We have noted that below. They also sell motors as complete systems with batteries and chargers.

Piktronik UWM1 – UMW10 On arriving at the linked page, there are links for each motor to download more information

- kW : 1, 2, 5, 6.5, 10 • Voltage : 16, 17, 30, 30, 30 • Current : 50, 92, 120, 150, 200 • HP : 1.4, 2.7, 6.8, 8.8, 13.6

- Motor Type : PMSM (permanent-magnet synchronous)

- Weight (kg) : 18, 23, 25, 51, 95

- Propeller/RPM/Torque : 2 blade fixed – 4 blade fixed • RPM : 1100, 1200, 1850, 1200, 1000 • Torque (nM) : 7, 14, 27, 51, 95

- Other : Aside from the complete system detailed below the motors alone come in different configurations: 1kW and 2kW: steerable pod or fixed pod, 5kW: steerable pod, fixed pod, transom mount, 6.5kW: steerable pod or transom mount, 10kW: steerable pod or transom mount

- Country of Manufacture : Slovenia

Piktronik SYS Systems 1kW – 10kW On arriving at the linked page, there are links for each motor to download more information

Piktronic sells their motors in complete system kits for each of the motor sizes detailed above. Complete system includes: motor, motor controller, display monitor, cables, siwthces, fuses, battery charger, remote comtrol, steering arm, installation tube, tiller handle, propeller

Rim Drive Technology

Click here to view RIM Drive Technology motors for sale in the Plugboats Marketplace

»» Rim Drive Technology website

Rim Drive technology is a Netherlands company with a line of rim motors in which the propeller blades are affixed to a rim rather than a central hub. There are no wearing parts within the motor and much reduced chance of weeds or other debris snagging or clogging. The motors are available as outboards, pods, azimuths and thrusters. The company offers complete systems or standalone batteries, controllers, monitors and other accessories. The pods in the Guide are sorted as 24V, 48V and 48V+. All pods are available with extended shaft options to reduce hull effects on the rim drive water flow for quieter and smoother operation.

24V Pods POD 3.0, POD 5.0

- kW : 3.0, 5.0 • Voltage : 24 • HP : 6.5, 11.0 • Thrust (kg) : – 31, 62

- Battery : Sold separately, recommended LiFePO4 available from Rim Drive

- Running Time : Suggested 4-5 hours with recommended Rim Drive battery pack

- Shaft Length (cm) : N/A extended shaft length available

- Propeller Diameter (mm) : 86, 133

- Weight (motor only) (kg) : 3.5, 5.0

- Other : One year warranty for non-commercial use, Completely waterproof (IP68), Efficiency 90+, Includes 2m cable set

- Price : €3,340, €4,000

48V Pods: 5 motors POD 0.5, POD 3.0, POD 5.0, POD 11.0, POD 15.0

- kW : 0.5, 3.0, 5.0, 9, 11, 16 • Voltage : 48 • HP : 1, 6.5, 10, 20, 28 • Thrust (kg) : – 7, 31, 62, 156, 250

- Running Time : Up to 7 hours with suggested Rim Drive battery pack

- Propeller Diameter (mm) : 65, 86, 133, 212, 341

- Weight (motor only) (kg) : 2.5, 3.5, 5.0, 14.0, 70.0

- Price : €3,300, €3,400, €4,000, €6,850, €18,000

96V, 110V, 400V Pods POD 25.0, POD 30.0, POD 50.0

- kW : 25, 30, 50 • Voltage : 96, 110, 400 • HP : 42, 52, 74 • Thrust (kg) : – 380, 400, 750

- Running Time : Average 3 hours with suggested Rim Drive battery pack

- Propeller Diameter (mm) : 341, 341, 341

- Weight (motor only) (kg) : 70, 70, 75

- Price : €25,000, €25,000, €48,000

Steerable Pods (8 models) Steerable POD 3.0, 5.0, 8.0, 11.0, 15.0, 25.0, 30.0, 50.0

- kW : 3, 5, 8, 11, 15, 25, 30, 50 • Voltage : 48, 48, 48, 48, 48, 96, 110, 400-550 • HP : 42, 52 • Thrust (kg) : 31, 62, 120, 156, 195, 350, 400, 750

- Weight (kg) : 21.5, 23, 32, 32, 37, 110, 110, 110

- Other : Rotatable up to 200 degrees, Waterproof hull passthrough, Stainless steel or glass fibre seal available, Salt water resistant (IP68), Motor controller included, Joystick, steering wheel or CAN controlled

- Price : €7,350, €8,225, €12,075, €12,375, €14,900, €31,995, €31,995, €55,500

»» SeaDrive website

SeaDrive is a Norwegian manufacturer that has an innovative approach to pods, saildrives and all electric boat motors for which they received a nomination for a 2019 DAME Award. The concept is that the basic motors can be configured: fixed pods, steerable pod, a saildrive or lift-up azimuth side pod – also with the ability to have the propellers arranged for push propulsion or pull propulsion. There are also regenerative versions available. The pod motor systems come in three power ratings: 7.5, 15 and 30.

SeaDrive Modular Pods/Saildrives/Lift-Up Azimuths

- kW : 5-7.5, 10-15, 20-30 • Voltage : 48, 96, 144 • Current : NA • HP : 7.5, 15, 32 • Static Thrust: 90, 160, 300

- Weight (kg) : Motor Weight: Aluminum: 20, Bronze 23. Total Weight differs by configuration

- Propeller/RPM/Torque : Fixed or folding • RPM : N/A • Torque N/A

- Other : re-generative versions and TABLET/PC control.

- Country of Manufacture : Norway

»» TEMA website

TEMA is a Croatian company that makes highly regarded electric motors that can be purchased alone or in systems for marine, industrial and power generation applications. Their saildrive system uses their SPM132 series of very efficient compact permanent magnet motors. The motors operate on either DC or AC voltages and can be powered from battery systems (48 96Vdc) or generators.

TEMA SYS Systems 1kW – 10kW Download .pdf of Systems configuration Download .pdf of SPM Motors

- kW : For each of their models TEMA has dual figures – kW output at 1800/3600 RPM. The 5 models range in listed power from 12/19kW to 35/57kW • Voltage : There 48 and 96 Voltage availble for all models. • Current : 50, 92, 120, 150, 200 • HP : At 1800/3600 RPM they range from 25/39 to 47/76

- Motor Type : PMAC (Permanent Magnet AC), PMS (Permanent Magnet Synchronous) • Air cooled

- Weight (kg) : 73, 93, 110, 130, 148

- Propeller/RPM/Torque : Propeller not supplied • RPM : 1800/3600 across all motors • Torque (nM) : Maximum: 70, 111, 145, 178, 205

- Other : Includes all components: e-motor, motor controller, saildrive, marine throttle, display, plug and play wiring. Efficiency: 95%.

- Country of Manufacture : Croatia

»» Torqeedo website

Torqeedo is the world’s leading manufacturer of electric outboards. The company was founded in 2004 by Dr Christoph Ballin and Dr Friedrich Böbel when they decided they could build a better electric motor than the one on the boat Dr. Ballin had just purchased. The company offers trolling motors, inboards, outboards and pod motors and works with BMW’s battery division as well as partnering with many of the world’s premier boat designers and manufacturers. It may be useful to download the full Torqeedo Catalogue

Torqeedo Cruze FP Pod 2.0 – 4.0 Operating instruction .pdfs can be downloaded from link above

- kW : 2, 4 • Voltage : 2kW: 24, 4kW: 48 • Current : N/A • HP : 6, 9.9 • Static Thrust 155 lbs, 189 lbs

- Motor Type : Brushless External Rotor Motors with Rare-earth Magnets • Operating efficiency 56%.

- Weight (kg) : 15.4, 15.8 Propeller/RPM/Torque : 3 blade fixed or folding • RPM : 1300

- Other : GPS on-board computer & display: Real-time speed, input power. Operates with lithium or AGM/lead-gel batteries, exact battery status and remaining range available when using Torqeedo battery. Emergency magnetic kill switch.

- Price (MSRP): $US 4,549, 4,999

Torqeedo Cruze FP Pod 10.0 Operating instruction .pdfs can be downloaded from link above

- Recommended Boat Size: <10 tons kW : 10 • Voltage : 48 • Current : N/A • HP : 20 • Static Thrust ≤ 405 lbs

- Weight (kg) : 33.5

- Propeller/RPM/Torque : 5 blade fixed or folding • RPM : 1400

- Other : Includes: Remote throttle, integrated on-board computer with GPS-based range calculation, 70 mm² cable set (3 m) including fuse and main switch, plug connector. 2 year warranty.

- Price (MSRP): $8,999

Torqeedo Cruze FP Saildrive 10.0 Operating instruction .pdfs can be downloaded from link above

- kW : 10 • Voltage : 48 • Current : N/A • HP : 20 • Static Thrust ≤ 405 lbs

- Weight (kg) : 37

Torqeedo Deep Blue 25 Saildrive

- Recommended Boat Size: <50 tons

- kW : 25 continuous, 33 peak • Voltage : 345 • Current : N/A • HP : 40 • Static Thrust ≤ 405 lbs

- Motor Type : Brushless External Rotor Motors with Rare-earth Magnets • Operating efficiency 55%.

- Weight (kg) : 125, 314 total system including 1 battery

- Propeller/RPM : Propeller : not included • RPM : 1200

- Price (MSRP): On Request with requirements input

Table: Searchable and Sortable

Get all the latest electric boats and boating news delivered to your mailbox!

Sign up here for the plugboats newsletter..

IT’S FREE!

Email address:

No, thanks.

Terms and Conditions - Privacy Policy

Did You Know That We Offer Contract to Closing Services? Click Here to Find Out More.

Need Marine Financing? Apply Here With Our Partner, First Approval Source

- Catamaran Interviews

- Catamaran Reviews

- Buying Advice

- Selling Advice

- Woods Design Advice

- Americat 3014

- Balance 526

- Bali 40 Catspace

- Beneteau Blue II

- Broadblue 346

- Broadblue 38 Prestige

- Broadblue 385

- Broadblue 435

- Broadblue 46

- Catalac 10M

- Catalac 11M

- Catalac 12M

- Catalac 900

- Catana 42 S

- Chris White 48 Voyager

- Chris White 55

- Corsair F28 R

- De Villiers

- Dolphin 460

- Endeavour 30

- Endeavour 35 Victory

- Endeavour 36

- Endeavour 44

- Endeavour 44 TrawlerCat

- Fortuna 36 Island Spirit

- Fortuna 401 Island Spirit

- FP 32 Maldives

- FP 35 Tobago

- FP 37 Antigua

- FP 38 Athena

- FP 39 Fidji

- FP 40 Lavezzi

- FP 40 Lucia

- FP 40 Summerland MY

- FP 41 Lipari

- FP 42 Astrea

- FP 42 Venezia

- FP 43 Belize

- FP 44 Helia

- FP 44 Orana

- FP 46 Bahia

- FP 46 Casamance

- FP 48 Salina

- FP 56 Marquises

- FP 57 Sanya

- FP 60 Eleuthera

- FP Saona 47

- Gemini 3000

- Gemini 3200

- Gemini 3400

- Grainger 420 Mystery Cove

- Hirondelle 7M

- Lagoon 37 TPI

- Lagoon 42 TPI

- Lagoon 43 PC

- Leopard 39 PowerCat

- Leopard 45 Classic

- Leopard 47 PowerCat

- Leopard 51 PowerCat

- Leopard 53 PowerCat

- Maine Cat 30

- Maine Cat 41

- Matrix 450 Vision

- Matrix 760 Silhouette

- Maverick 400

- Maverick 420

- Maverick 440

- Nautitech 40

- Nautitech 442

- Nautitech 46 Open

- Nautitech 47

- Outremer 40

- Outremer 45

- Outremer 50 Standard

- Outremer 55

- Privilege 37

- Privilege 39

- Privilege 42

- Privilege 43

- Privilege 435

- Privilege 45

- Privilege 465

- Privilege 48 Transcat

- Privilege 482

- Privilege Serie 5

- Prout 31 Quest

- Prout 33 Quest

- Prout 34 Event

- Prout 35 Snowgoose

- Prout 37 Snowgoose

- Prout 37 Snowgoose Elite

- Prout 38 Manta

- Prout 39 Escale

- Royal Cape 45

- Royal Cape 530 Majestic

- Royal Cape Majestic 500

- Sailcraft 30 Iroquois

- Sailcraft 32 Comanche

- Sailcraft 35 Cherokee

- Sailcraft 41 Apache

- Sailcraft 44 Apache

- Wildcat 350

- Seawind 1000

- Seawind 1160

- Seawind 1200

- Seawind 1260

- Seawind 1600

- Solaris 36 Sunrise

- Solaris 36 Sunstar

- St Francis 44

- St Francis 48

- St Francis 50

- Stealth 11.8

- Heavenly Twins 26

- Ocean Twins 38

- Voyage 380 Maxim

- Voyage 400 Norseman

- Voyage 430 Norseman

- Voyage 450 Cabriolet

- Voyage 47 Mayotte

- Wharram 38 Tiki

- AMI 320 Renaissance

- Woods 22 Wizard

- Woods 35 Banshee

- Woods 35 Flica

- Woods 36 Scylla

- Woods 36 Vardo

- Woods 38 Transit

- Woods 40 Meander

- Xquisite X5

- Xquisite X5+

Catamaran Drives Types – Outboards, Inboards and Drive Shaft Configurations

- Post author By Patrick Davin

- Post date September 23, 2020

- 1 Comment on Catamaran Drives Types – Outboards, Inboards and Drive Shaft Configurations

Catamarans these days have many options for their engine based propulsion, even more than monohulls due to the more diverse configurations of a catamaran. The traditional twin diesel engines is a popular arrangement, and dual or single outboard configurations are also becoming popular. When choosing an inboard engine, you then often have a decision to make in drive shaft configuration: traditional straight shaft, or a saildrive.

The drive type has long lasting consequences for how you use and maintain a boat, so it’s an important factor. It affects how much power you have for motoring into strong winds or against current, fuel economy, reliability, maintenance needs, and purchase plus maintenance costs. And let’s not forget noise level and liveability – the choice between diesel inboards vs gas outboards can have a big impact on cabin storage areas and engine noise level.

Single Gas Outboard

Outboards have always been common in smaller sailing boats (under about 30 feet) that don’t require a great deal of power to get them moving. However they’re now becoming popular with larger catamarans as well, up to about 40 or 45 feet. They offer several unique advantages over inboard diesel engines. First and foremost, they’re significantly less expensive than a diesel engine – a 30hp outboard might be around $4,000 while a 30hp diesel could easily be $20,000. They’re also smaller and lighter, and take up less space inside the hull – freeing up storage or accommodation space.

Smaller catamarans or lightweight ones can often get by with a single outboard. The advantages are in the weight and cost savings of only having one engine instead of two, and only one engine to maintain. The downside is it may make maneuvering in a marina a bit trickier, and there’s no backup engine if the one outboard has an issue.

Twin Gas Outboards

Catamarans have a unique advantage over monohulls in that they can have more than one engine. Two engines provide many advantages – redundancy in case one fails at sea and greater maneuverability in marinas. Many catamarans can motor reasonably fast on only one engine – which some owners do to save fuel and reduce engine hours – but two are nice to have for the redundancy and for pivoting easily in tight quarters.

Twin outboards are usually mounted at the aft end of each hull, or in drop-down lockers built into the cockpit. Some catamarans with twin outboards have them located in lockers under the cockpit seats (ex, Seawind 1160 lite and PDQ 36) which is handy because they can be raised to eliminate drag yet are easily accessible to work on, and don’t add an unsightly appendage to the stern.

Speaking with an owner of a Seawind 1160 lite catamaran with dual outboards located in a well under the cockpit seats, he noted appreciating all the space they freed up vs having inboard diesels installed at the aft of each hull. In the space normally occupied by diesel engines, they store two bikes, a kayak, a water heater and other gear.

He also loves that they’re quiet, fuel efficient, emissions efficient, and can be raised with electric tilt for zero drag in the water while sailing. One disadvantage he noted is the impellers are harder to replace, and he’s hauling out to make it easier to replace the gear oil along with impellers.

Outboards may not have as long a life span as diesels, but when it comes time to replace, he can do so relatively easily anywhere in the world, with much less work than replacing a diesel. One possible disadvantage is in rough seas or steep swell, outboard props may come out of the water – whether this can happen will depend on the design and size of the catamaran.

Single Diesel Inboard/Outboard Sillette Drive

A somewhat unique option is the Sillette Sonic drive (common on Gemini 105 catamarans) which is a type of saildrive. It allows using an inboard engine with an outboard drive leg exterior to the boat. The drive leg can be raised while under sail, providing the same no drag advantage as outboards, while having the engine inboard which protects it from saltwater. The drive leg is typically mounted from the bridgedeck or in a pod underneath.

Diesel Inboards with Direct Drives

Inboard diesel engines have historically been the most common option in mid to large size monohulls and multihulls. Diesels excel in delivering high working power while being exceptionally reliable over a long service life. Since a diesel is located inside the boat, it’s exposed to a lot less seawater than outboards are. Diesels can also support a powerful alternator to charge the house batteries, reducing the need for alternate power generation such as solar, wind or a generator.

The straight shaft is the more traditional option and is a tried and tested design from work boats to pleasure boats. In this design the propellor shaft connects from the engine (via a shaft coupling), passes through the hull of the boat (via a shaft seal) and connects to the propellor. Typically there will also be a strut forward of the propellor to stabilize the spinning prop shaft.