- Boats & Gear

- Instructional

- Cruising Stories

- Cruising Destinations

- Race Results

- Race Reports

- Racing Technique

- Submit a Classified Ad

- Boats for Sale

- All Classifieds

- Terms & Conditions

- Your Dashboard

- Seattle Area Racing Calendar (SARC)

- 48° North Cruising Rally

- Croatia Flotilla

- The Perry Carbon Cutter Project

This article originally appeared in the January 2017 “Boat Show Preview” issue of 48° North.

There is something uniquely “Pacific Northwest” happening in Anacortes right now. There are four identical 43’ offshore cruising cutters being built out of carbon fiber at Betts Boats. These are a special custom project, designed by the prolific Pacific Northwest yacht designer, Robert “Bob” Perry.

To me, this project represents the capacities and complexities found within our group of local industry professionals and sailing enthusiasts. Like so many of the extraordinary projects that come out of our region, these carbon cutters have one eye looking back toward the traditional and the other looking to the leading edge of modern development, design, and technology. Whether fast boats built of wood or, in this case, cruising boats built of carbon, this creativity, variety, and versatility are on display. The cherry on top is to find the knowledge, talent, skills, and facilities to make it all happen right here in western Washington.

Perry is a Northwest guy who has been successfully drawing boats since the seventies, so you may already know him personally. Even if you don’t know him, you certainly know his designs: the Valiant 40; the Baba 30, 35, and 40; the Tayana 37; the Passport 40; a fleet of Islander designs; the Nordic 40 and 44; among many, many others. The Perry brand is built on boats that pass the sail test as well as the eye test – they’re generally known to be beautiful, capable, and fast. Though he’s best known for his cruising boat designs, Perry has designed boats to be built out of carbon before, including the powerful and banshee-fast racer/cruiser Icon .

When I’ve described this Perry Carbon Cutter project, I’ve gotten looks that range from inquisitive to perplexed to skeptical. Yacht design seems to me to be as much a balance of priorities and compromise as it is a balance of art and science. In this case, the priority was to build comfortable passage-making yachts with a traditional look utilizing modern materials. Though Perry says he shared the vision with the client immediately, as with all custom projects, many elements and motivations for this project are very client-driven. Perry’s answer to many of my questions didn’t go far beyond, “that’s what the client had in mind, and I got to figure out how to make it happen.”

While these are not high performance boats, the carbon build will make these boats perform better than many similar looking boats. However, it may not be for the reason you’d guess. It was when I asked, “Why build offshore cruisers out of carbon fiber?” that Perry helped me have that ah-ha moment.

“Well, first off, these are not going to be light displacement boats. The total displacement is going to be over 35,000 pounds.” Perry noted that this is not significantly lighter than a similar boat would be if built out of fiberglass. But here’s the kicker: Perry told me, “Most boats like this are actually under-ballasted. The weight of the hull is usually so heavy that the boat becomes far too heavy if you use as much ballast as you probably should. One of the main benefits of building these boats out of carbon fiber is that we can get the ballast-to-displacement ratio to roughly 45%.”

As a comparison, consider several of Perry’s proven offshore designs. The Valiant 40, which has a long fin keel has a ballast-to-displacement ratio of 36%. The full-keeled Baba 40 makes it to 41%. When I learned about the ballast-to-displacement ratio on these carbon cutters, I immediately thought of the only boats I knew of that were in that range, ultralight displacement boats like the Moore 24 (49%) and the Santa Cruz 27 (50%). At this comparison, Perry smiled and said, “Well, it’s getting there.”

Perry went on, “You could build this boat out of pretty much anything, but, the further you get away from carbon, the less ballast you would get.”

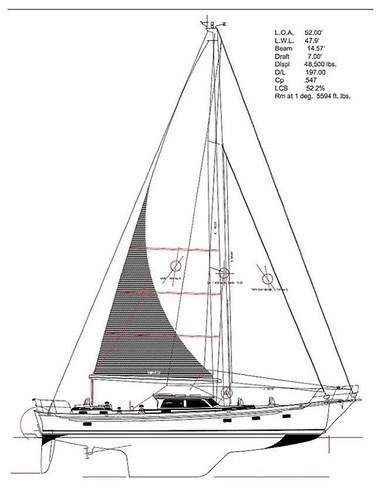

Perry noted that “the displacement-to-length ratio is about the same as a Valiant 40. It’s 43’ long, and it’s almost all waterline.” So, while this is a carbon boat that will never plane and Perry thinks it’s unlikely that it will even surf, he did say, “this is a boat that will do eight or nine knots in pretty much any direction for days on end.”

Though the construction is cutting edge, there’s a lot that’s quite traditional about the design. These cutters have transom-hung rudders, which was a specific request of the client. Perry sees that the rudder, the lower freeboard, and the deck layout all contribute to the more traditional look. On first glance, hull #1 reminded me slightly of a big Bristol Channel Cutter. I learned that Perry and this client each had Atkin cutters in their minds as inspiration.

One of the first things Perry showed me when we entered the shop was the carbon strut that extends from the bottom aft corner of the keel to the bottom of the outboard rudder. Like essentially all the parts on the boat, this was a custom part built (of carbon fiber, of course) right there in the Betts shop. It sat right next to the female mold that one side of the strut came out of. Perry told me that he wasn’t positive it was necessary, but the strut will protect the rudder and the propeller while supporting the rudder tip. It’s also replaceable in the event of damage or failure. While he acknowledged that the boat could function without it, this part has been dubbed, “the chastity strut,” because if you didn’t have it, you might be f**ked.

Once the drawings began taking shape, the client asked Perry about where to have the boats built. “I told him I had been thinking about Jim Betts in Anacortes,” Perry remarked. The client was floored. As a PNW local, he is in Anacortes frequently. A local builder appealed to both Perry and the client, so they could both participate in the process. Indeed, they’ve been there at least weekly since the build began.

Getting to poke around the Betts Boats shop would have been cool regardless of the project they were working on. Their whole team was friendly, welcoming, and professional. Betts is one of the nation’s leading carbon composite boat building specialists. Founded more than 45 years ago, Betts Boats has built everything from the always-competitive Sierra 26s, Uno and Dos , to speedy Bieker Riptide designs like Longboard , to a variety of cruising boats, and even an America’s Cup boat for a campaign in 2000, America True .

Betts Boats lead designer, Neil Racicot, notes that in the Perry Carbon Cutters, they have kind of a dream project. It’s a custom job, so, they get to have the fun and challenge of designing, engineering, and manufacturing custom parts. But since there are multiple units, they can use component designs for the next few projects, making the construction of the later hulls more efficient. There is also a possibility of doing some testing on the early components that will benefit or streamline their systems for the later hulls. It’s a massive job, but all parties seemed pleased with the progress and the results thus far.

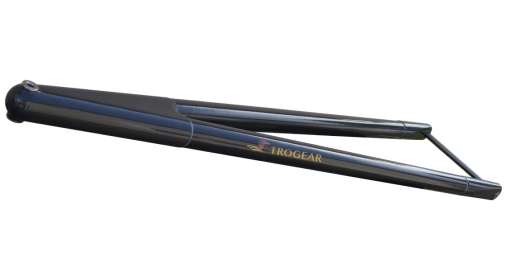

Racicot and the Betts team have had a hand in the design process with Perry, in addition to the build and the all the custom tooling. One instance where Racicot tweaked the design is the bowsprit. Perry had drawn one originally, but Racicot had a couple of alterations that would make the carbon construction easier. Ultimately, Racicot found a few ways to improve functionality as well, particularly for the windlass and anchor roller positioning, and Perry told me he likes Racicot’s design of the bowsprit better than his own.

Racicot also engineered stanchion base attachments that would fail (if they fail) above the structure of the bulwark and could be easily replaced underway, without having to drill or re-seal bases through the deck.

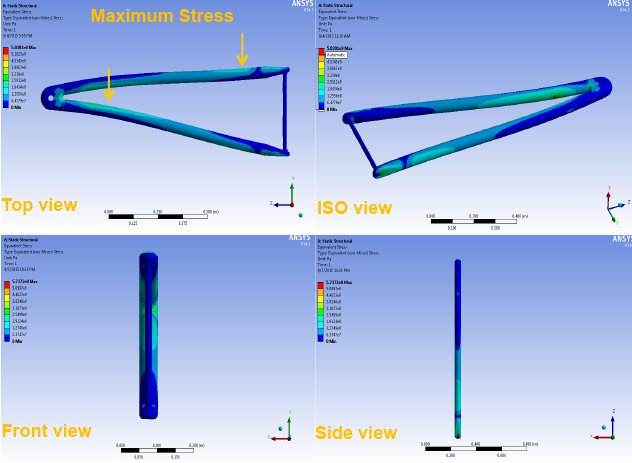

I asked Racicot how different the carbon fiber layup was for a cruising boat than a carbon race boat. He raised his eyebrows, “very different.” He told me they work with Jim Antrim, a naval architect and engineer in Califiornia, for load testing of their components and composites. Ultimately, the carbon fiber layup is much heavier than most of the boats Betts build s. They have the license to slightly overbuild, because the overall hull weight will still be much lighter than a similar fiberglass boat.

Betts made the molds in-house. A key factor in what kind of mold to use is the choice, again a request from the client, to have internal ballast. For this reason, a male mold is required, as it would otherwise be very difficult to ensure even construction in the deep cavity of the keel sump.

The choice of internal ballast displays the client’s desire for a careful and conservative approach. There are arguments for both types of ballast – internal and external – but a well-made internally ballasted boat is less likely to lose its keel. I trust that there are great examples in the world, but it is hard for me to imagine bolting on a 16,000 pound lead keel to anything.

The keel itself is a notable design feature. It is long, compared to more performance-oriented fin keels, and deep compared to standard full keels. The capacity for increased ballast is accomplished in both dimensions. Internal ballast is most common among full-keel boats, including many that Perry has designed. The client’s original request was for a full keel. But after some deliberation with Perry the three-quarter keel with the “chastity strut” was the choice.

One of the complications of internal ballast is that you don’t have soft lead to limit damage from a grounding. As a means to counteract that concern, the lay-up begins to mix some fiberglass with the carbon composite as you move from the hull to the bottom of the keel. There’s more than an inch of pure fiberglass on the keel’s bottom edge. Accomplishing a layup that thick with carbon would have been both too time consuming and too expensive, plus at this position on the boat, the additional weight is only a benefit.

The client’s desire for a meticulous product has influenced some other elements of the design. He seems like a real belt-and-suspenders kind of a guy, which can be a great attribute in an ocean sailor. A good example is that he wanted two antennas for the SSB radio, instead of only one. Perry had drawn the boat with a single backstay, but considering the double antenna request from the client, he split the backstays and the antennas will be inside these composite stays, one on each side.

Another example of the very conservative approach for these boats is the fact that they don’t have any thru-hulls. Utilizing technology typical of larger boats, the carbon cutters use a sea-chest, which the Betts team designed and manufactured to fit the boat. Making the boats safer yet, the cutters have three water-tight bulkheads.

These cutters don’t have traditional chain plates, either. The shroud attachments, which are integrated into the massive rolled bulwarks reminded me of some I’ve seen on carbon TP52s. Those shrouds will be attached to a two-spreader carbon fiber mast. I asked Perry whether he was loading the boat up with a lot of extra sail power, given the extra ballast. While he drew a more modern cutter sailplan than the boats that had inspired the design, he didn’t add a ton of extra sail. This is in line with his thinking that many boats are under-ballasted. He’s hoping the client won’t have to shorten sail too early in offshore conditions.

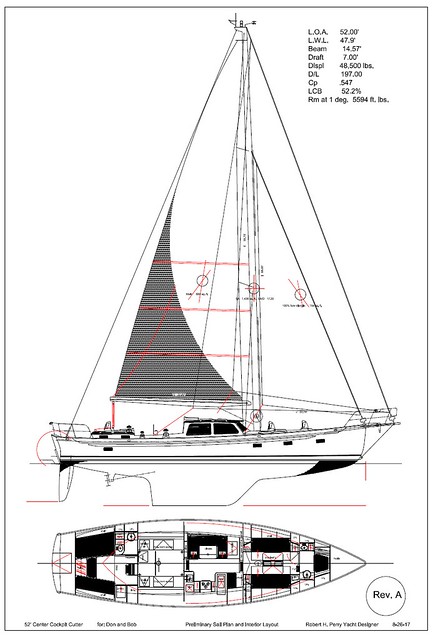

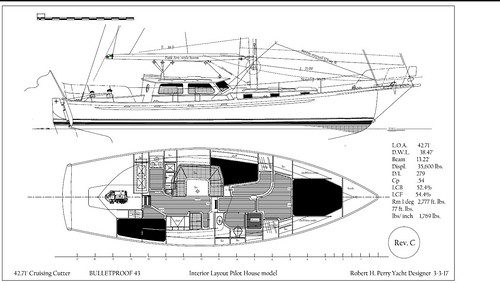

The interior layout of the cutters highlights their given purpose. They are spacious with ample storage, but very ocean friendly. There’s not a double-berth to be found on the boat, and all the single berths were designed to be proper sea berths. The glossy carbon fiber handrails give the interior a sexy look. Access to the engine is superb, and there’s still space for a genset and a huge battery bank.

Ultimately, my impressions are that these will be beautiful and sturdy boats. I admit it wasn’t exactly my expectation. Having spent some time on carbon boats, I know them to be fast and light, but also know that they must be treated with care in a way I never experienced on fiberglass boats. I figured these would be burlier than those race boats, but I didn’t have a read on exactly how much. The answer is clearly a lot burlier! These boats will be fast cruisers that are going to love the ocean. I think they will be a striking boat at the dock, at anchor, and especially under sail.

I can’t wait to see one in action. The planned splash date for hull #1 is sometime in April. As I understand it, there will be a production break between the completion of the second boat and the beginning of production on the third, to allow for new information from sail testing.

One of my favorite parts of my meeting with Perry at the Betts facility was asking him whether he’d been this involved with the production of any of his other designs. Though he has spent a great deal of time in boat yard sover the years, he said this was by far the most time he’s spent at every step in the process. He continued, “It’s been remarkable to see it all come together, all the aspects of individual work and expertise. I’d compare it to a symphony, where so many parts must have mastery on their own, but work together for a common purpose.” To that, I’ll say to all parties: BRAVO!

Joe Cline is the Editor of 48° North . Photos by Boomer Depp (available at www.flickr.com/photos/boomerdepp ) and Joe Cline.

Joe Cline has been the Managing Editor of 48° North since 2014. From his career to his volunteer leadership in the marine industry, from racing sailboats large and small to his discovery of Pacific Northwest cruising —Joe is as sail-smitten as they come. Joe and his wife, Kaylin, welcomed a baby girl to their family in December 2021, and he is enjoying fatherhood while still finding time to sail, make music, and tip back a tasty IPA every now and again.

Boats & Gear , Featured

March Products News

March 19, 2024

Boat Reviews , Featured

Boat Test: Allures 45.9

March 7, 2024

February Products News

February 20, 2024

January Products News

January 23, 2024

December Products News

December 19, 2023

48° North Boat Test: Arksen 30

December 13, 2023

Perry 43 Carbon Cutters

Professional BoatBuilder Magazine

Four carbon cutters.

By Dan Spurr , May 24, 2017

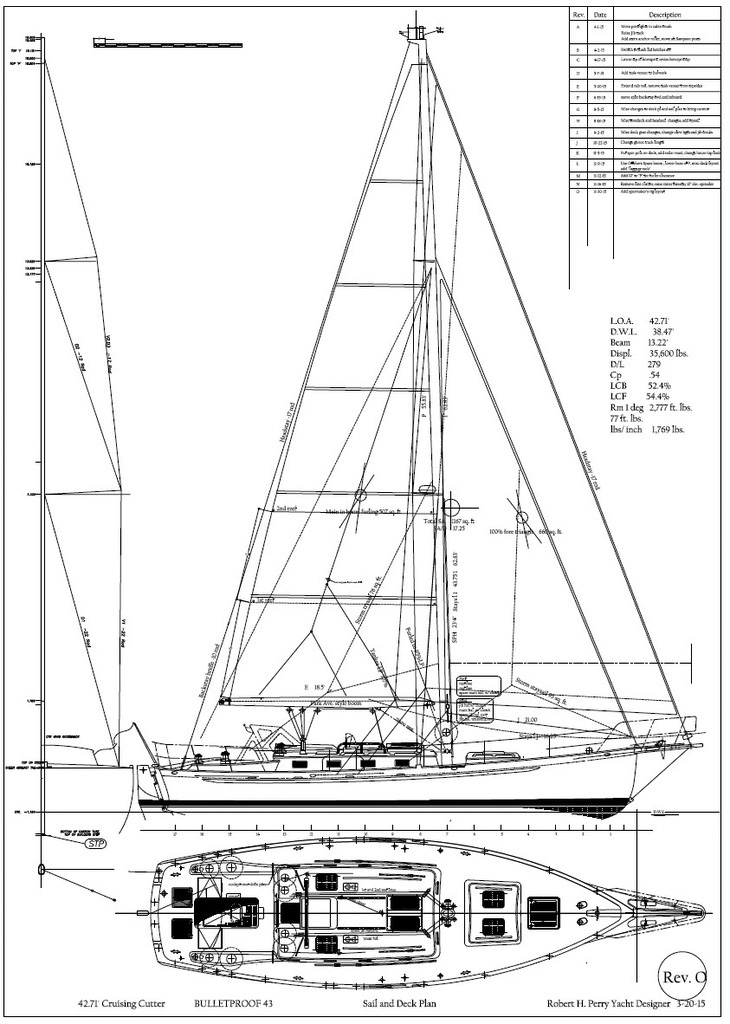

Drawings of Robert Perry’s carbon cutter show the large keel that accommodates enough water and fuel tankage for extended periods at sea. There’s no centerline double berth here; all sleeping accommodations are secure sea berths. The D/L is 279.

Lord knows not every boatbuilder recovered from the latest economic maelstrom of biblical proportions to hit the industry (2008), but “Survivor III” Jim Betts (see Professional BoatBuilder No. 139) of Anacortes, Washington, must feel like he’s walking on water these days, thanks to clients who ordered four cookie-cutter carbon cutters—that is, four identical 43 ‘ (13.1m) Robert Perry–designed offshore cruising sailboats.

Here’s the backstory: The principal client, who owns land in the San Juan archipelago northwest of Seattle, is a sailor who once owned a Cape George Cutter. Worried about environmental, manmade, and God-made disasters like Armageddon, he commissioned Perry to design a sailing yacht, somewhat similar to the cutter, that can voyage from the U.S. to New Zealand nonstop. Or in Perry’s words, “Go offshore and stay offshore.” That was the June 2015 design brief. And the result is unusual.

From their first discussions the client and partners insisted on an outboard rudder for easy inspection and sheer ruggedness; Perry says that by removing a long titanium rod it can be disengaged from the boat in the water (confessing in an aside that he wonders why anyone would undertake such an operation). A split house, found on some old Atkin designs, also made the early must-have feature list.

The four cutters are being built at Betts Boats. Here, the keel is laminated with a quasi-isotropic (QI) carbon fiber stack comprising four layers: 11-oz 0/90, 1-oz double bias (DB), 11-oz 0/90, and 11-oz DB on either side of 1⁄2″ (12mm) E-glass. The bilge outside skin is in place and is made with the same QI stack on either side of 1″ (25mm) Corecell A500. Above the waterline, the laminate has yet to be applied over the core, but the M100 Corecell used above the waterline to minimize print-through is visible. One can also see the single-skin area in way of the chainplates, where there is no core; instead, Betts employs the basic eight-layer hull laminate detailed above, along with two additional 20-oz carbon unis running down to the keel. All lamination utilizes API’s DR-5 rubber-toughened epoxy.

Notable is the very large keel, dictated by the humongous capacity of water and fuel tanks—1,136 l and 606 l (300 gal and 160 gal), respectively. Perry says he wanted external lead ballast, but “if all the tanks are in the bilge, you’re never going to see your keelbolts. So we went internal. There is plenty of volume in that big keel.” Which ended up, at the client’s wish, somewhat longer and carried farther forward than Perry preferred.

There are no individual through-hulls. A sea chest located at the bottom of the keel, starboard side aft, receives all intakes through a perforated 10 “ x 10 “ (254mm x 254mm) brass plate; and a dump chest at the bottom of the keel, portside forward, discharges all fluids.

When discussing possible builders, Perry suggested Betts Boats, which would be convenient for the client to visit, given Anacortes is home to the ferry terminal for the San Juan Islands. “Next time I visited the client,” Perry says, “he’d visited Jim [Betts] and said the boats would be carbon fiber. End of story. He’s a pilot, technically astute. He’s not afraid of carbon fiber like some sailors. Jim thinks carbon is the best material to build a boat, and he’s done 17 or 18 now.” Though Betts gave the client a fixed bid, according to Perry the client preferred to work on time-and-materials, saying bids are excuses to cut corners, and he doesn’t want any corners cut.

The choice of carbon had a significant impact on the vertical center of gravity. Perry: “The boat has a ballast/displacement ratio of 45%. For lack of a better name, this boat is basically a Bristol Channel Cutter. They were built of timber and had pretty low ballast/displacement ratios. They laid over on their ears and did the best they could. We have a VCG 1.8 ‘ [550mm] below the waterline. Most cruise boats are 4–6 “ [102mm–152mm] above LWL. We’re 2 ‘ [610mm] lower . Carbon boat. Carbon rig. Pretty cool.”

The displacement/length ratio is 279, not much higher than Perry’s Hall of Fame Valiant 40 (12m), regarded as the first of a new breed of “performance cruisers” when it was drawn in 1973.

With the hull righted and painted with ProLine epoxy barrier coat and Awlgrip topcoat, work on the interior begins, with foam-cored carbon bulkheads and panels.

To build the cutters, a female mold was rejected because of the need to orient the carbon fiber fabrics along identified load paths, so a male plug was constructed with CNC-cut poplar frames and strip-planked. Corecell of varying densities is sandwiched in the hull, deck, and interior. No plywood is to be found on the boat.

The generous sail plan incorporates a long bowsprit to fly an asymmetrical spinnaker. Below it is a false foam-filled fabrication on the stem, a sort of “crash box.” But that’s not its purpose. “I have a little tumblehome in the stern,” Perry explains, “and in order to get the boat off the male plug we have to push the hull aft as we lift it up. In order to push it off we had to put an angle on the bow that gave us the geometry and tolerance to lift the hull clear. A big chunk of foam goes on to define the stem that you see, bonded with carbon fiber.” That, and another reason: the aesthetic of the Bristol Channel Cutter’s formidable bowsprit.

Auxiliary power is a 48-hp (36-kW) naturally aspirated (the client wanted an old-fashioned, simple power plant with as few computer chips as possible) Volvo diesel coupled to a sail drive, a configuration that Perry heartily endorses. “Less vibration. Less noise. The shafts are horizontal. Easy to put in and take out,” he says. “They’re a builder’s dream.”

As of this writing, hull #1 is nearly finished; carpenters are dry-fitting the teak caprails. Hulls #2 and #3 are right-side up and progressing with interior joinery and hull fairing. Hull #4 is in the on-deck circle. Perry lives but an hour from Betts’s shop and so visits every Wednesday, with his Portuguese water dog, Ruby, to mark progress—a boon to the owners.

The Lord helps those who help themselves, and in Perry and Betts, owners of these four carbon cutters have placed themselves in very capable hands.

Robert H. Perry Yacht Designers, 11530 Tulare Way West, Tulalip, WA 98271 USA, tel. 360–652–7771, website www.perryboat.com .

Betts Boats, 416 34th St., Anacortes, WA 98221 USA, tel. 360–299–2311. Send mail to: P.O. Box 991, Friday Harbor, WA 98250. Website www.jbeinc.com .

Read more Construction , Design , Rovings articles

- Van der Werff’s Curved Wood

A Dutch yard adopts composite panel molding technology to build boats from preshaped wooden hull sections.

- Departures: Carl Chamberlin

Passionate, competent, considerate, modest, and thoughtful is how designer and boatbuilder Carl Chamberlin is remembered by those who knew him. He died last November at age of 75 in Port… Read more »

- SAFE Boats Regains Small-Business Status with Employee Ownership

More than 20 years ago, Professional BoatBuilder ran a feature titled “God, Country and Fast Boats” (No. 85, page 64) about SAFE Boats International (SBI), a Bremerton, Washington–based manufacturer of aluminum boats…. Read more »

Recent Posts

- Find out how 3D printing can help your boatbuilding with MASSIVIT

- SNAME Powerboat Symposium Is Back

- Companies (85)

- Construction (106)

- Design (161)

- Drawing Board (10)

- Education (25)

- Environment (16)

- Events (21)

- Materials (50)

- Obituary (18)

- People/Profiles (49)

- Products (16)

- Propulsion Systems (32)

- Racing (16)

- Repair (37)

- Rovings (317)

- Short Cuts (3)

- Sponsored Partner News (14)

- Systems (80)

- Task Sheet (1)

- Uncategorized (26)

- Wood to Glass (7)

ProBoat.com Archives

Robert H. Perry Yacht Designers

Currently in build, four carbon fiber cutters, catari - a 62' ketch at pacific seacraft.

Made in RapidWeaver

Full carbon pilot cutter

B uilt almost entirely out of prepreg carbon composite with long chord appendages and a towering rig, the Baltic 117 Perseverance looks timeless but she isn’t remotely traditional

What happens when you combine the skills and talents of Baltic Yachts and Dykstra? You don’t end up with a stately but sedate ‘spirit of tradition’ sort of yacht. You’ll more likely get a handsome, high-performance wolf in impeccably tailored sheep’s clothing. Thus it was with their first collaboration, the 67-metre ketch Hetairos and the same can be said for their second, delivered last summer: the 35-metre (117ft) sloop Perseverance.

‘The ethos of this project is a pure sailing boat,’ says Henry Hawkins, Baltic Yachts’ EVP. ‘Often on large sailing yachts you don’t get a pure sailing experience because you lose the feel, which is so important and it’s something that Baltic Yachts works hard to maintain. There are distinct parallels with Hetairos in terms of the look of the boat but in most respects she is quite different, more modern but at the same time less extreme.’

Perseverance and Hetairos both stand out from Dykstra’s other pilot cutter style yachts in several ways. They’re built in carbon, not aluminium and significantly lighter and stiffer as a result. They both have notably deep draught, which improves their handling and helm response as well as performance, and they each have an enormous amount of sailpower.

However, Hetairos is extensively optimised for racing, yet at the same time more classic in her proportions with a ketch rig and a tapered stern. Perseverance by contrast is primarily a cruiser but has timeless rather than classic lines and her broader stern, sloop rig and waterline length are more akin to a typical modern yacht.

Also, as Dykstra is keen to point out, the differences between the two yachts show how these full custom projects are led by the wishes and choices of the clients. The next time the two companies collaborate on a yacht, it could be a completely different type of vessel. Concept & hull design true to her name, Perseverance was a long time coming.

Dykstra and their interior design counterparts, deVosdeVries design, had already spent almost three years developing, refining and revising the concept before Baltic Yachts became involved. The two Dutch design studios had worked together on the client’s previous yacht – an 18-metre (60ft) pilot cutter-style cruiser built in aluminium by Claasen Shipyard – and were tasked with scaling up the style and concept of that boat into a high performance superyacht twice the size.

‘The design brief was classic elegance but performance orientated with good seakeeping capability for long hauls, Atlantic crossings, that sort of thing,’ says Erik Wassen, the lead naval architect for Perseverance and many of Dykstra’s previous pilot cutter-style yachts.

Another key aspect of the brief was to create an efficient charter yacht with broad appeal. Full custom yachts often grow during the design process, but this one went the other way.

’Initially we had a larger boat in aluminium but that changed because aluminium has its drawbacks,’ Wassen says. ‘Corrosion issues, it’s less stiff, it’s heavier. So we squeezed that 40- metre boat into a smaller composite package, 10cm here, 10cm there. You lose weight, you lose volume but you gain interior space by having a sandwich structure rather than frames and a skin. Basically it’s the same layout, though. Also when you lose displacement you lose propulsive power requirement, fuel consumption. It’s a knock-on effect. That was the compromise and it ended up as 117ft.’

The underwater shapes of Dykstra’s designs bear no resemblance to an actual Bristol Channel pilot cutter, of course, nor anything else of that vintage but they do share one functional benefit with the boats that inspired them.

‘The old pilot cutter guys figured out that a longer waterline pays off in seakeeping capabilities,’ Wassen says. ‘Having a sharp bow with a long waterline, it’s a no-brainer. Also, as the forefoot is straight the interior extends further forward so you can have proper stowage in the forepeak. With a spoon bow you might have five metres sticking out beyond the waterline but there’s not much volume that you can use.’

In Perseverance that same thinking is applied at the other end of the hull. ‘Most pilot cutters we design have more overhang at the stern,’ Wassen says. ‘This one is all about maximising waterline length. So the challenge for us was to get the hull out of the water in a proper way and find a good compromise between waterline length, shape and appearance.’

Rig, sailplan & deck plan Dykstra’s Wassen designed the sailplan, working with Doyle Sails and Hall Spars. Light wind performance was a top priority so the rig is huge but it has three sets of spreaders rather than four.

‘If you could reduce weight considerably by having an additional set, I wouldn’t be against it,’ he says. ‘But that was not the case. We did a calculation run with Hall Spars and it all appeared to work out quite nicely and the mast section is not excessively stiff. So then you get a reduction in windage.’

As a result, the mast’s longitudinal sections are stiffened with high-modulus carbon fibre but intermediate-modulus carbon is used in the sides of the mast. A square-top mainsail was put on hold.

‘It is a lot of complication for a small gain,’ Wassen says. ‘You do get a few more square metres, the sail is probably easier to trim, it’s a bit more forgiving in puffs. There are benefits but also the drawback of always needing to use your runners and not having a fixed backstay, making the whole rig more vulnerable. That’s something you need to weigh. The boat is fast as she is, and doesn’t actually need a square top main.’

Even so, the rig is designed to incorporate a square top in years to come as the boat develops, to make sure it’s a simple adaption later on. The deck plan is firmly focused on simplicity.

‘There are a number of fixed points,’ Wassen says. ‘You can have a tweaker on the code sheet and kite sheet if you want. There are all sorts of racing capabilities but in normal operation it’s a very simple and straightforward sailplan.’

The mainsheet and main halyard are on below-deck captive winches, the jib and staysail sheets are led aft via pin-stop cars to primary winches on the coamings.

‘We have the halyards on locks, partly because I like to sail with a clean foredeck,’ Perseverance’s captain Ryan Taylor explains. ‘Also because we only have two mast winches although we do have plenty of jammers.’

Construction

The entire boat is built in Gurit Sprint prepreg carbon with a foam core. Her actual weight is within three per cent of her design weight, which would be remarkable for most builders but is about normal for Baltic Yachts. Despite appearances, there is actually very little solid wood on board.

‘Over a long period of time we have learned how to manage and create a solid wood look for our exterior details,’ says Tommy Johansson, Baltic’s project manager for Perseverance. ‘The basic idea is to have a solid, stiff structure behind the wood. No shortcuts can be taken so we use top quality prepreg carbon sandwich construction. For thick, solid-looking wood like cap rails and bulwarks, several layers of teak are glued and bonded onto a lightweight core. Wood selection starts with the procurement and the final selection is down to the sharp eye of the carpenters.’

Quality control is strict and frequent checks are made. On Perseverance, the deckhouses were finished with 8mm teak veneer. There isn’t enough freeboard for a Pink Gin IV-style through-hull door to be practical on Perseverance – you’d have to crawl, rather than walk through it – so there’s a side boarding platform instead, which folds out from the port topside with a boarding ladder that extends up to the deck. A carbon fibre beam runs along the bottom of the aperture in the hull skin to maintain stiffness and the panel behind the fold-out platform is structural, fixed to the hull skin.

Hybrid propulsion

The main engine is a diesel-electric hybrid with two 129kW diesel generators charging a big bank of lithium ion batteries, powering an electric motor that drives a Hundested controllable pitch propeller on a conventional straight shaft.

‘It’s a 128kw/h system,’ Johansson says. ‘Perseverance can run in silent mode for up to nine hours with everything running at maximum capacity.’

The 600V system is stepped up to 750V and distributed via a DC bus. This setup requires a dedicated technical cooling circuit with full dual redundancy built in.

‘Even the hydraulics are high voltage, with two 50kW pumps the size of a small coffee table,’ Taylor says. ‘So we have 100kW on demand.’

‘There has been a huge amount of development since we installed our first hybrid system on Canova in 2019,’ Hawkins says. ‘The biggest difference between then and now is battery technology.’

It’s still far from off-the-shelf technology, though, and a hybrid setup with an extended battery capacity for silent running provides a challenge for the notoriously tight engine room spaces found on sailing yachts.

‘With high-voltage electrical systems it’s crucial to find the right equipment and partners,’ Hawkins says. ‘You can’t just go out and buy a set of class approved batteries for a setup like the one we developed for Perseverance. We had to find a suitable supplier and then help them get class approval. That’s a typical challenge we face.’

Halfway through this process they had to switch battery suppliers, so the engine room had to be reconfigured to fit a different set of equipment. The hybrid drive is designed to regenerate electricity from a boatspeed of 10kts.

‘At lower speeds the advantage of starting to regenerate are lower because you also reduce the boatspeed a lot,’ Wassen says. ‘When the wetted surface is still the largest component of the resistance, then the effect on boatspeed when you start regenerating is really large. The resistance curve is not linear, it goes up by the fourth power or so. When you’re at a higher point of the resistance curve, the effect on boatspeed is a lot less.’

In practice, the regeneration is working well.

‘We’ve been getting about 8-12kW out of it under sail,’ Taylor says. ‘It doesn’t quite meet the full load of all systems but it does extend our silent mode for at least 50 per cent longer. Our power consumption can be anything from 10-20kW and we aim to regenerate 10-15kW.’

Smart systems

‘There is a major focus on energy saving solutions,’ Hawkins says. ‘Not just producing green energy but also where possible not using it at all. An example of this is the smart cabins system. This allows systems such as air conditioning to either be run manually or automatically via the PLC. In the long term it can learn how the cabins are typically used and run the hotel systems accordingly by default. It knows when the cabins are occupied and when they aren’t. Full cooling all day long wastes a lot of energy. There are sensors built into all hatches so it knows whether they are open or closed. To illustrate the efficiency of the AC system I’ve used the example of a week-long charter in the Caribbean,’ he says. ‘The system can identify which cabins are unoccupied, reduce the AC in there during the day and start cooling them down again from around 5pm. During the course of the night, the cabin temperature can be increased from say 18°C to 20 or 21°C and the body will still feel cool. That can make a huge difference to AC compressor run time, the equivalent of 19.2 litres of diesel a day. And we’re also trapping the waste heat and using it to produce hot water. Over the course of a year we can save more than 9,000 litres of diesel just with that. With lots of little bits chipping away at the big picture you can make a massive difference.’

Sailing performance

The real proof of a boat, of course, is in the sailing. Perseverance is still in the shakedown phase but Taylor describes her as ‘super easy, fast and efficient. The rig is exceptionally powerful for this boat and she is very stiff. I’m very happy with the Doyle Structured Luff and Cableless sails . Just like it says in the adverts, the luff does project to windward.’ ‘On the delivery down to the Med we had some great sailing,’ he says. ‘We logged 20+kts off Holland quite easily when we weren’t really trying. We started off with the code zero but then changed down to main with one reef and full blade. The wind was about 20-25kts. We’ve been out in winds up to about 35kts; so far I’ve played it safe with the weather. She also goes very well in light airs.’

Interior design and layout

Despite her classic exterior look, the interior is anything but traditional. ‘We came to a certain styling in the previous boat and that was the starting point for the new boat,’ says the lead designer, Michiel de Vos of deVosdeVries design. ‘We elaborated on that and added lots of wooden details. All the exterior deck hardware has a matt finish, there’s no polished chrome and it’s similar inside. It’s a very nice boat to walk through because the styling is consistent throughout. There isn’t a major difference between the guest and crew areas, we have made it a bit simpler and more hard wearing in the crew area but the main details are the same.’

When the decision was made to build a smaller composite boat, fitting everything into the GA was a challenge for de Vos. ‘Her length was reduced by 17ft and her beam was narrowed but we have managed to deliver the same functionality,’ he says.

Baltic Yachts made a virtual 3D model of the interior, with virtual reality headsets to make it easy to visualise and check the size, shape and styling of the various spaces. Significant weight savings were made in the interior, ‘but that’s not down to us,’ de Vos says. ‘We designed it and Baltic made it work in a lightweight way. They are very good at that. For example In the master cabin the bed frame is carbon with a wood veneer and the top part of the frame is finished with thin, removable leather. The double curved bottom piece is a composite structure.’

For de Vos, the stand-out interior space is the side-by-side saloon and galley. ‘It’s conceived as a communal area and can be opened up with a drop down TV that serves as a partition, or it can be enclosed completely,’ he says. ‘For charter use, you can set up a buffet/ breakfast bar on the central island.’

In a boat designed for long-distance voyaging, it might seem strange to have the master cabin in the bow rather than further aft where the boat’s motion in a seaway will be more comfortable. However, it makes a lot of sense when Perseverance is working as a charter yacht and nearly always anchored or moored overnight. For ocean passages, there are guest cabins next to the keel trunk where the boat’s motion is minimal. The quality of finish throughout the yacht is a showcase of Baltic Yachts’ skills.

‘The combination of light stained brushed oak with all wood grain oriented vertically, including all cornices, marrying with the dark-stained maple floor edges is a stunning look,’ Johansson says. ‘Every single metal piece in the interior has a PVD coating or colour to match. It’s hard to believe all interior parts are fitted with fast mounts when looking in the joints and the lineup of different parts. Every single part can be disassembled to access the systems behind.’

The best thing about it, though, is the absence of noise. ‘It’s a floating interior on rubber-mounted carbon fibre beams,’ Johansson says. ‘Creating a silent boat was one of our main goals.’

Taylor concurs: ‘This boat is super quiet even with the generators running, with noise levels usually less than 42dB. That’s partly due to the quality of the sound insulation but also the science and past development that Baltic has put into noise reduction over the years. Even the hydraulic lines are double insulated. You can’t hear any noise at all in the master cabin.’

ABO UT DOYLE SAILS // As sailors, our obsession with sailing connects us to the water. The water is our playground, a sanctuary where we seek enjoyment, a competitive playing field where we race; it’s sometimes our home and always a place that unlocks our sense of adventure wherever that adventure might take us.

Our obsession with sailing takes us to every corner of the world and onboard every yacht. We become part of teams, share in the adventures of friends and families, sharing our knowledge and experience with those who have the same passion for sailing as we do. Sailing is in our DNA, where the water unlocks our sense of adventure. We are the custodians of a legacy that has been supporting sailors for close to four decades, and while our world changes around us, our commitment to sailors who seek the same enjoyment and adventure as we do hasn’t.

From our sailors to yours, we are your experts in sailing. Your adventure starts with Doyle. By sailors, for sailors.

A BOUT SEAHORSE MAGAZINE // Take advantage of our very best subscription offer or order a single copy of this issue of Seahorse. Online at: www.seahorse.co.uk/shop and use the code TECH20 Or via email: [email protected]

The Ultimate Guide to Sail Types and Rigs (with Pictures)

What's that sail for? Generally, I don't know. So I've come up with a system. I'll explain you everything there is to know about sails and rigs in this article.

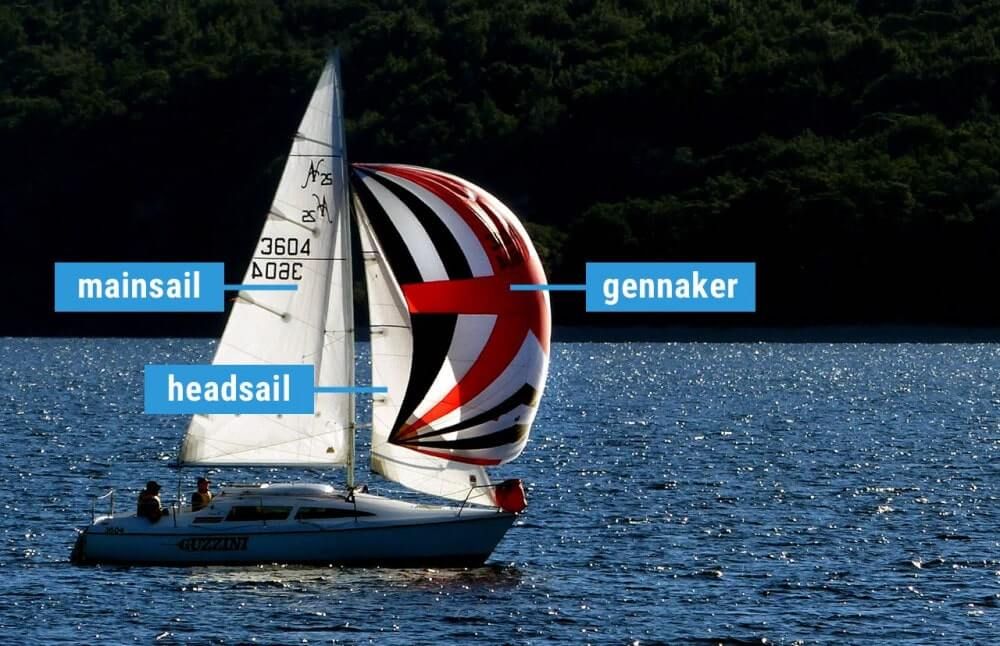

What are the different types of sails? Most sailboats have one mainsail and one headsail. Typically, the mainsail is a fore-and-aft bermuda rig (triangular shaped). A jib or genoa is used for the headsail. Most sailors use additional sails for different conditions: the spinnaker (a common downwind sail), gennaker, code zero (for upwind use), and stormsail.

Each sail has its own use. Want to go downwind fast? Use a spinnaker. But you can't just raise any sail and go for it. It's important to understand when (and how) to use each sail. Your rigging also impacts what sails you can use.

On this page:

Different sail types, the sail plan of a bermuda sloop, mainsail designs, headsail options, specialty sails, complete overview of sail uses, mast configurations and rig types.

This article is part 1 of my series on sails and rig types. Part 2 is all about the different types of rigging. If you want to learn to identify every boat you see quickly, make sure to read it. It really explains the different sail plans and types of rigging clearly.

Guide to Understanding Sail Rig Types (with Pictures)

First I'll give you a quick and dirty overview of sails in this list below. Then, I'll walk you through the details of each sail type, and the sail plan, which is the godfather of sail type selection so to speak.

Click here if you just want to scroll through a bunch of pictures .

Here's a list of different models of sails: (Don't worry if you don't yet understand some of the words, I'll explain all of them in a bit)

- Jib - triangular staysail

- Genoa - large jib that overlaps the mainsail

- Spinnaker - large balloon-shaped downwind sail for light airs

- Gennaker - crossover between a Genoa and Spinnaker

- Code Zero or Screecher - upwind spinnaker

- Drifter or reacher - a large, powerful, hanked on genoa, but made from lightweight fabric

- Windseeker - tall, narrow, high-clewed, and lightweight jib

- Trysail - smaller front-and-aft mainsail for heavy weather

- Storm jib - small jib for heavy weather

I have a big table below that explains the sail types and uses in detail .

I know, I know ... this list is kind of messy, so to understand each sail, let's place them in a system.

The first important distinction between sail types is the placement . The mainsail is placed aft of the mast, which simply means behind. The headsail is in front of the mast.

Generally, we have three sorts of sails on our boat:

- Mainsail: The large sail behind the mast which is attached to the mast and boom

- Headsail: The small sail in front of the mast, attached to the mast and forestay (ie. jib or genoa)

- Specialty sails: Any special utility sails, like spinnakers - large, balloon-shaped sails for downwind use

The second important distinction we need to make is the functionality . Specialty sails (just a name I came up with) each have different functionalities and are used for very specific conditions. So they're not always up, but most sailors carry one or more of these sails.

They are mostly attached in front of the headsail, or used as a headsail replacement.

The specialty sails can be divided into three different categories:

- downwind sails - like a spinnaker

- light air or reacher sails - like a code zero

- storm sails

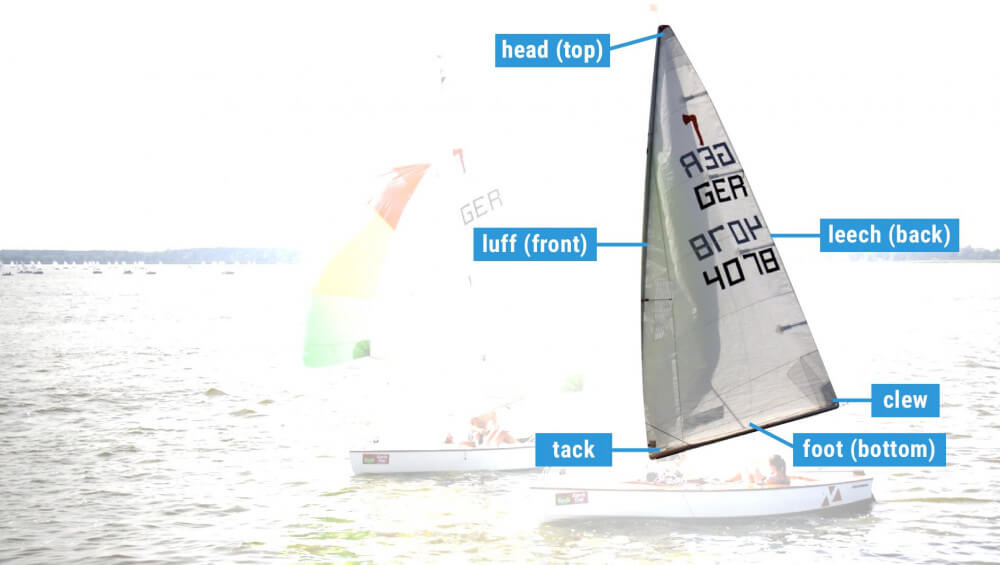

The parts of any sail

Whether large or small, each sail consists roughly of the same elements. For clarity's sake I've took an image of a sail from the world wide webs and added the different part names to it:

- Head: Top of the sail

- Tack: Lower front corner of the sail

- Foot: Bottom of the sail

- Luff: Forward edge of the sail

- Leech: Back edge of the sail

- Clew: Bottom back corner of the sail

So now we speak the same language, let's dive into the real nitty gritty.

Basic sail shapes

Roughly speaking, there are actually just two sail shapes, so that's easy enough. You get to choose from:

- square rigged sails

- fore-and-aft rigged sails

I would definitely recommend fore-and-aft rigged sails. Square shaped sails are pretty outdated. The fore-and-aft rig offers unbeatable maneuverability, so that's what most sailing yachts use nowadays.

Square sails were used on Viking longships and are good at sailing downwind. They run from side to side. However, they're pretty useless upwind.

A fore-and-aft sail runs from the front of the mast to the stern. Fore-and-aft literally means 'in front and behind'. Boats with fore-and-aft rigged sails are better at sailing upwind and maneuvering in general. This type of sail was first used on Arabic boats.

As a beginner sailor I confuse the type of sail with rigging all the time. But I should cut myself some slack, because the rigging and sails on a boat are very closely related. They are all part of the sail plan .

A sail plan is made up of:

- Mast configuration - refers to the number of masts and where they are placed

- Sail type - refers to the sail shape and functionality

- Rig type - refers to the way these sails are set up on your boat

There are dozens of sails and hundreds of possible configurations (or sail plans).

For example, depending on your mast configuration, you can have extra headsails (which then are called staysails).

The shape of the sails depends on the rigging, so they overlap a bit. To keep it simple I'll first go over the different sail types based on the most common rig. I'll go over the other rig types later in the article.

Bermuda Sloop: the most common rig

Most modern small and mid-sized sailboats have a Bermuda sloop configuration . The sloop is one-masted and has two sails, which are front-and-aft rigged. This type of rig is also called a Marconi Rig. The Bermuda rig uses a triangular sail, with just one side of the sail attached to the mast.

The mainsail is in use most of the time. It can be reefed down, making it smaller depending on the wind conditions. It can be reefed down completely, which is more common in heavy weather. (If you didn't know already: reefing is skipper terms for rolling or folding down a sail.)

In very strong winds (above 30 knots), most sailors only use the headsail or switch to a trysail.

The headsail powers your bow, the mainsail powers your stern (rear). By having two sails, you can steer by using only your sails (in theory - it requires experience). In any case, two sails gives you better handling than one, but is still easy to operate.

Let's get to the actual sails. The mainsail is attached behind the mast and to the boom, running to the stern. There are multiple designs, but they actually don't differ that much. So the following list is a bit boring. Feel free to skip it or quickly glance over it.

- Square Top racing mainsail - has a high performance profile thanks to the square top, optional reef points

- Racing mainsail - made for speed, optional reef points

- Cruising mainsail - low-maintenance, easy to use, made to last. Generally have one or multiple reef points.

- Full-Batten Cruising mainsail - cruising mainsail with better shape control. Eliminates flogging. Full-length battens means the sail is reinforced over the entire length. Generally have one or multiple reef points.

- High Roach mainsail - crossover between square top racing and cruising mainsail, used mostly on cats and multihulls. Generally have one or multiple reef points.

- Mast Furling mainsail - sails specially made to roll up inside the mast - very convenient but less control; of sail shape. Have no reef points

- Boom Furling mainsail - sails specially made to roll up inside the boom. Have no reef points.

The headsail is the front sail in a front-and-aft rig. The sail is fixed on a stay (rope, wire or rod) which runs forward to the deck or bowsprit. It's almost always triangular (Dutch fishermen are known to use rectangular headsail). A triangular headsail is also called a jib .

Headsails can be attached in two ways:

- using roller furlings - the sail rolls around the headstay

- hank on - fixed attachment

Types of jibs:

Typically a sloop carries a regular jib as its headsail. It can also use a genoa.

- A jib is a triangular staysail set in front of the mast. It's the same size as the fore-triangle.

- A genoa is a large jib that overlaps the mainsail.

What's the purpose of a jib sail? A jib is used to improve handling and to increase sail area on a sailboat. This helps to increase speed. The jib gives control over the bow (front) of the ship, making it easier to maneuver the ship. The mainsail gives control over the stern of the ship. The jib is the headsail (frontsail) on a front-and-aft rig.

The size of the jib is generally indicated by a number - J1, 2, 3, and so on. The number tells us the attachment point. The order of attachment points may differ per sailmaker, so sometimes J1 is the largest jib (on the longest stay) and sometimes it's the smallest (on the shortest stay). Typically the J1 jib is the largest - and the J3 jib the smallest.

Most jibs are roller furling jibs: this means they are attached to a stay and can be reefed down single-handedly. If you have a roller furling you can reef down the jib to all three positions and don't need to carry different sizes.

Originally called the 'overlapping jib', the leech of the genoa extends aft of the mast. This increases speed in light and moderate winds. A genoa is larger than the total size of the fore-triangle. How large exactly is indicated by a percentage.

- A number 1 genoa is typically 155% (it used to be 180%)

- A number 2 genoa is typically 125-140%

Genoas are typically made from 1.5US/oz polyester spinnaker cloth, or very light laminate.

This is where it gets pretty interesting. You can use all kinds of sails to increase speed, handling, and performance for different weather conditions.

Some rules of thumb:

- Large sails are typically good for downwind use, small sails are good for upwind use.

- Large sails are good for weak winds (light air), small sails are good for strong winds (storms).

Downwind sails

Thanks to the front-and-aft rig sailboats are easier to maneuver, but they catch less wind as well. Downwind sails are used to offset this by using a large sail surface, pulling a sailboat downwind. They can be hanked on when needed and are typically balloon shaped.

Here are the most common downwind sails:

- Big gennaker

- Small gennaker

A free-flying sail that fills up with air, giving it a balloon shape. Spinnakers are generally colorful, which is why they look like kites. This downwind sail has the largest sail area, and it's capable of moving a boat with very light wind. They are amazing to use on trade wind routes, where they can help you make quick progress.

Spinnakers require special rigging. You need a special pole and track on your mast. You attach the sail at three points: in the mast head using a halyard, on a pole, and on a sheet.

The spinnaker is symmetrical, meaning the luff is as long as its leech. It's designed for broad reaching.

Gennaker or cruising spinnaker

The Gennaker is a cross between the genoa and the spinnaker. It has less downwind performance than the spinnaker. It is a bit smaller, making it slower, but also easier to handle - while it remains very capable. The cruising spinnaker is designed for broad reaching.

The gennaker is a smaller, asymmetric spinnaker that's doesn't require a pole or track on the mast. Like the spinnaker, and unlike the genoa, the gennaker is set flying. Asymmetric means its luff is longer than its leech.

You can get big and small gennakers (roughly 75% and 50% the size of a true spinnaker).

Also called ...

- the cruising spinnaker

- cruising chute

- pole-less spinnaker

- SpinDrifter

... it's all the same sail.

Light air sails

There's a bit of overlap between the downwind sails and light air sails. Downwind sails can be used as light air sails, but not all light air sails can be used downwind.

Here are the most common light air sails:

- Spinnaker and gennaker

Drifter reacher

Code zero reacher.

A drifter (also called a reacher) is a lightweight, larger genoa for use in light winds. It's roughly 150-170% the size of a genoa. It's made from very lightweight laminated spinnaker fabric (1.5US/oz).

Thanks to the extra sail area the sail offers better downwind performance than a genoa. It's generally made from lightweight nylon. Thanks to it's genoa characteristics the sail is easier to use than a cruising spinnaker.

The code zero reacher is officially a type of spinnaker, but it looks a lot like a large genoa. And that's exactly what it is: a hybrid cross between the genoa and the asymmetrical spinnaker (gennaker). The code zero however is designed for close reaching, making it much flatter than the spinnaker. It's about twice the size of a non-overlapping jib.

A windseeker is a small, free-flying staysail for super light air. It's tall and thin. It's freestanding, so it's not attached to the headstay. The tack attaches to a deck pad-eye. Use your spinnakers' halyard to raise it and tension the luff.

It's made from nylon or polyester spinnaker cloth (0.75 to 1.5US/oz).

It's designed to guide light air onto the lee side of the main sail, ensuring a more even, smooth flow of air.

Stormsails are stronger than regular sails, and are designed to handle winds of over 45 knots. You carry them to spare the mainsail. Sails

A storm jib is a small triangular staysail for use in heavy weather. If you participate in offshore racing you need a mandatory orange storm jib. It's part of ISAF's requirements.

A trysail is a storm replacement for the mainsail. It's small, triangular, and it uses a permanently attached pennant. This allows it to be set above the gooseneck. It's recommended to have a separate track on your mast for it - you don't want to fiddle around when you actually really need it to be raised ... now.

Why Use Different Sails At All?

You could just get the largest furling genoa and use it on all positions. So why would you actually use different types of sails?

The main answer to that is efficiency . Some situations require other characteristics.

Having a deeply reefed genoa isn't as efficient as having a small J3. The reef creates too much draft in the sail, which increases heeling. A reefed down mainsail in strong winds also increases heeling. So having dedicated (storm) sails is probably a good thing, especially if you're planning more demanding passages or crossings.

But it's not just strong winds, but also light winds that can cause problems. Heavy sails will just flap around like laundry in very light air. So you need more lightweight fabrics to get you moving.

What Are Sails Made Of?

The most used materials for sails nowadays are:

- Dacron - woven polyester

- woven nylon

- laminated fabrics - increasingly popular

Sails used to be made of linen. As you can imagine, this is terrible material on open seas. Sails were rotting due to UV and saltwater. In the 19th century linen was replaced by cotton.

It was only in the 20th century that sails were made from synthetic fibers, which were much stronger and durable. Up until the 1980s most sails were made from Dacron. Nowadays, laminates using yellow aramids, Black Technora, carbon fiber and Spectra yarns are more and more used.

Laminates are as strong as Dacron, but a lot lighter - which matters with sails weighing up to 100 kg (220 pounds).

By the way: we think that Viking sails were made from wool and leather, which is quite impressive if you ask me.

In this section of the article I give you a quick and dirty summary of different sail plans or rig types which will help you to identify boats quickly. But if you want to really understand it clearly, I really recommend you read part 2 of this series, which is all about different rig types.

You can't simply count the number of masts to identify rig type But you can identify any rig type if you know what to look for. We've created an entire system for recognizing rig types. Let us walk you through it. Read all about sail rig types

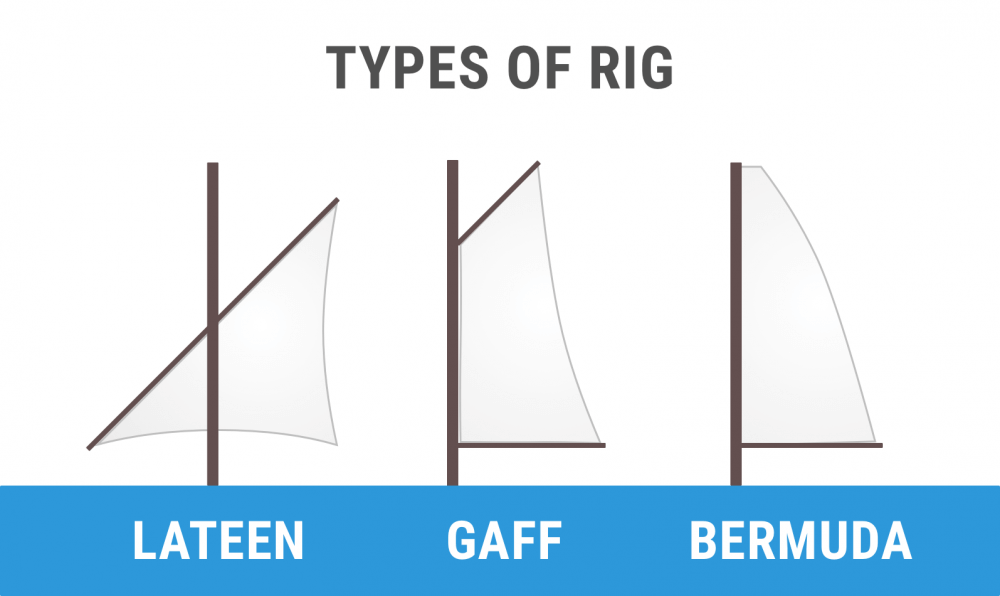

As I've said earlier, there are two major rig types: square rigged and fore-and-aft. We can divide the fore-and-aft rigs into three groups:

- Bermuda rig (we have talked about this one the whole time) - has a three-sided mainsail

- Gaff rig - has a four-sided mainsail, the head of the mainsail is guided by a gaff

- Lateen rig - has a three-sided mainsail on a long yard

There are roughly four types of boats:

- one masted boats - sloop, cutter

- two masted boats - ketch, schooner, brig

- three masted - barque

- fully rigged or ship rigged - tall ship

Everything with four masts is called a (tall) ship. I think it's outside the scope of this article, but I have written a comprehensive guide to rigging. I'll leave the three and four-masted rigs for now. If you want to know more, I encourage you to read part 2 of this series.

One-masted rigs

Boats with one mast can have either one sail, two sails, or three or more sails.

The 3 most common one-masted rigs are:

- Cat - one mast, one sail

- Sloop - one mast, two sails

- Cutter - one mast, three or more sails

1. Gaff Cat

2. Gaff Sloop

Two-masted rigs

Two-masted boats can have an extra mast in front or behind the main mast. Behind (aft of) the main mast is called a mizzen mast . In front of the main mast is called a foremast .

The 5 most common two-masted rigs are:

- Lugger - two masts (mizzen), with lugsail (cross between gaff rig and lateen rig) on both masts

- Yawl - two masts (mizzen), fore-and-aft rigged on both masts. Main mast much taller than mizzen. Mizzen without mainsail.

- Ketch - two masts (mizzen), fore-and-aft rigged on both masts. Main mast with only slightly smaller mizzen. Mizzen has mainsail.

- Schooner - two masts (foremast), generally gaff rig on both masts. Main mast with only slightly smaller foremast. Sometimes build with three masts, up to seven in the age of sail.

- Brig - two masts (foremast), partially square-rigged. Main mast carries small lateen rigged sail.

4. Schooner

5. Brigantine

This article is part 1 of a series about sails and rig types If you want to read on and learn to identify any sail plans and rig type, we've found a series of questions that will help you do that quickly. Read all about recognizing rig types

Related Questions

What is the difference between a gennaker & spinnaker? Typically, a gennaker is smaller than a spinnaker. Unlike a spinnaker, a gennaker isn't symmetric. It's asymmetric like a genoa. It is however rigged like a spinnaker; it's not attached to the forestay (like a jib or a genoa). It's a downwind sail, and a cross between the genoa and the spinnaker (hence the name).

What is a Yankee sail? A Yankee sail is a jib with a high-cut clew of about 3' above the boom. A higher-clewed jib is good for reaching and is better in high waves, preventing the waves crash into the jibs foot. Yankee jibs are mostly used on traditional sailboats.

How much does a sail weigh? Sails weigh anywhere between 4.5-155 lbs (2-70 kg). The reason is that weight goes up exponentially with size. Small boats carry smaller sails (100 sq. ft.) made from thinner cloth (3.5 oz). Large racing yachts can carry sails of up to 400 sq. ft., made from heavy fabric (14 oz), totaling at 155 lbs (70 kg).

What's the difference between a headsail and a staysail? The headsail is the most forward of the staysails. A boat can only have one headsail, but it can have multiple staysails. Every staysail is attached to a forward running stay. However, not every staysail is located at the bow. A stay can run from the mizzen mast to the main mast as well.

What is a mizzenmast? A mizzenmast is the mast aft of the main mast (behind; at the stern) in a two or three-masted sailing rig. The mizzenmast is shorter than the main mast. It may carry a mainsail, for example with a ketch or lugger. It sometimes doesn't carry a mainsail, for example with a yawl, allowing it to be much shorter.

Special thanks to the following people for letting me use their quality photos: Bill Abbott - True Spinnaker with pole - CC BY-SA 2.0 lotsemann - Volvo Ocean Race Alvimedica and the Code Zero versus SCA and the J1 - CC BY-SA 2.0 Lisa Bat - US Naval Academy Trysail and Storm Jib dry fit - CC BY-SA 2.0 Mike Powell - White gaff cat - CC BY-SA 2.0 Anne Burgess - Lugger The Reaper at Scottish Traditional Boat Festival

Hi, I stumbled upon your page and couldn’t help but notice some mistakes in your description of spinnakers and gennakers. First of all, in the main photo on top of this page the small yacht is sailing a spinnaker, not a gennaker. If you look closely you can see the spinnaker pole standing on the mast, visible between the main and headsail. Further down, the discription of the picture with the two German dinghies is incorrect. They are sailing spinnakers, on a spinnaker pole. In the farthest boat, you can see a small piece of the pole. If needed I can give you the details on the difference between gennakers and spinnakers correctly?

Hi Shawn, I am living in Utrecht I have an old gulf 32 and I am sailing in merkmeer I find your articles very helpful Thanks

Thank you for helping me under stand all the sails there names and what there functions were and how to use them. I am planning to build a trimaran 30’ what would be the best sails to have I plan to be coastal sailing with it. Thank you

Hey Comrade!

Well done with your master piece blogging. Just a small feedback. “The jib gives control over the bow of the ship, making it easier to maneuver the ship. The mainsail gives control over the stern of the ship.” Can you please first tell the different part of a sail boat earlier and then talk about bow and stern later in the paragraph. A reader has no clue on the newly introduced terms. It helps to keep laser focused and not forget main concepts.

Shawn, I am currently reading How to sail around the World” by Hal Roth. Yes, I want to sail around the world. His book is truly grounded in real world experience but like a lot of very knowledgable people discussing their area of expertise, Hal uses a lot of terms that I probably should have known but didn’t, until now. I am now off to read your second article. Thank You for this very enlightening article on Sail types and their uses.

Shawn Buckles

HI CVB, that’s a cool plan. Thanks, I really love to hear that. I’m happy that it was helpful to you and I hope you are of to a great start for your new adventure!

Hi GOWTHAM, thanks for the tip, I sometimes forget I haven’t specified the new term. I’ve added it to the article.

Nice article and video; however, you’re mixing up the spinnaker and the gennaker.

A started out with a question. What distinguishes a brig from a schooner? Which in turn led to follow-up questions: I know there are Bermuda rigs and Latin rig, are there more? Which in turn led to further questions, and further, and further… This site answers them all. Wonderful work. Thank you.

Great post and video! One thing was I was surprised how little you mentioned the Ketch here and not at all in the video or chart, and your sample image is a large ship with many sails. Some may think Ketch’s are uncommon, old fashioned or only for large boats. Actually Ketch’s are quite common for cruisers and live-aboards, especially since they often result in a center cockpit layout which makes for a very nice aft stateroom inside. These are almost exclusively the boats we are looking at, so I was surprised you glossed over them.

Love the article and am finding it quite informative.

While I know it may seem obvious to 99% of your readers, I wish you had defined the terms “upwind” and “downwind.” I’m in the 1% that isn’t sure which one means “with the wind” (or in the direction the wind is blowing) and which one means “against the wind” (or opposite to the way the wind is blowing.)

paul adriaan kleimeer

like in all fields of syntax and terminology the terms are colouual meaning local and then spead as the technology spread so an history lesson gives a floral bouque its colour and in the case of notical terms span culture and history adds an detail that bring reverence to the study simply more memorable.

Hi, I have a small yacht sail which was left in my lock-up over 30 years ago I basically know nothing about sails and wondered if you could spread any light as to the make and use of said sail. Someone said it was probably originally from a Wayfayer wooden yacht but wasn’t sure. Any info would be must appreciated and indeed if would be of any use to your followers? I can provide pics but don’t see how to include them at present

kind regards

Leave a comment

You may also like, 17 sailboat types explained: how to recognize them.

Ever wondered what type of sailboat you're looking at? Identifying sailboats isn't hard, you just have to know what to look for. In this article, I'll help you.

How Much Sailboats Cost On Average (380+ Prices Compared)

Own your first boat within a year on any budget.

A sailboat doesn't have to be expensive if you know what you're doing. If you want to learn how to make your sailing dream reality within a year, leave your email and I'll send you free updates . I don't like spam - I will only send helpful content.

Ready to Own Your First Boat?

Just tell us the best email address to send your tips to:

- Forums New posts Unanswered threads Register Top Posts Email

- What's new New posts New Posts (legacy) Latest activity New media

- Media New media New comments

- Boat Info Downloads Weekly Quiz Topic FAQ 10000boatnames.com

- Classifieds Sell Your Boat Used Gear for Sale

- Parts General Marine Parts Hunter Beneteau Catalina MacGregor Oday

- Help Terms of Use Monday Mail Subscribe Monday Mail Unsubscribe

Carbon Fiber Mast Upgrade

- Thread starter rgranger

- Start date Aug 4, 2022

- Forums for All Owners

- Ask All Sailors

- How long ago did you make the change?

- What did it cost?

- From whom did you source your rig?

- What were the considerations/tradeoffs you had to make?

- Why did you make the choice you made?

- How did you determine this number?

- Pitch and roll?

- If you added height, did you work with a sail loft to determine how to cut the new sails to maintain the location of the CE?

- Have there been any unwanted performance issues with the new rig?

- Would you do it again?

Are you interested in a CF mast for a particular size or kind of boat? Or just general information? I just read an article on this a few days ago, if I can remember where it was I'll post it.

Don S/V ILLusion

We made the switch about 6 years ago. Went from an aluminum furling mast which we didn’t like for numerous reasons to a boom furler and carbon mast. The performance difference is startling! i don’t recall &&& which entailed the mast, boom, new rigging and new sails but suspect those are dependent on boat size which probably can’t be extrapolated. the weight aloft savings was substantial. I can only subjectively compare before/after sailing characteristics other than to say it depends on how you use your boat. If we sailed only locally, I wouldn’t recommend the switch. The only thing I don’t like about the new mast is it makes it much more difficult without steps to ascend the mast. Otherwise, we are very happy.

dlochner said: Are you interested in a CF mast for a particular size or kind of boat? Or just general information? I just read an article on this a few days ago, if I can remember where it was I'll post it. Click to expand

Don S/V ILLusion said: The only thing I don’t like about the new mast is it makes it much more difficult without steps to ascend the mast. Otherwise, we are very happy. Click to expand

rgranger said: Thanks Don So would it be possible to add steps to a CF mast or is there something intrinsic about CF masts that make that impracticle? Click to expand

don, did you make the masts taller?

jon hansen said: don, did you make the masts taller? Click to expand

The Nor’Sea is a well designed small cruising boat. A Lyle Hess design. Originally he designed wood boats. I loved he’s philosophy. Lyle Hess "any boat that points her bow out to sea should be designed so that the crew need not worry about a safe return--no matter what tricks the weather may play” He had a hand in the design of the Montgomery boats. The 15 was my first pocket cruiser. Tough little boat. True to the Hess philosophy. A NorSea would serve you well. Bob Perry has been recently designing boats with CF masts and hulls. There is a builder/shop in Anacortes WA that has developed molds and produced some of his designs. They might be helpful. I’ll see if I can find a link for you.

The Perry Carbon Cutter Project - 48° North

James Betts Enterprises, Inc. (Betts Boats)

I should imagine it would seriously change the weight aloft to keel ratio considerably. If any of you have been moored in the water without a mast, I'm sure you understand. The few crew I've talked to on mega-sailing yachts with carbon fiber/line rigging have mentioned around 2k # difference aloft. Perhaps it makes little noticeable difference on big boats like those, but without a marine architect I can't see it as a favorable improvement on any boat.

capta said: I should imagine it would seriously change the weight aloft to keel ratio considerably. If any of you have been moored in the water without a mast, I'm sure you understand. The few crew I've talked to on mega-sailing yachts with carbon fiber/line rigging have mentioned around 2k # difference aloft. Perhaps it makes little noticeable difference on big boats like those, but without a marine architect I can't see it as a favorable improvement on any boat. Click to expand

My boating buddy built a 29' sloop with a carbon fiber mast and gaff rig. The mast is set in a tabernacle. The gaff rig allows for a shorter mast without having a smaller mainsail. He can raise and lower the mast by himself with the aid of a tripod.

heritage said: My boating buddy built a 29' sloop with a carbon fiber mast and gaff rig. The mast is set in a tabernacle. The gaff rig allows for a shorter mast without having a smaller mainsail. He can raise and lower the mast by himself with the aid of a tripod. Click to expand

JohnShannon

Your best bet might be to find a carbon mast already mounted on a boat then buy that boat.

Barnacle Bill

Had two J/32's sailing side by side. One with an aluminum mast - the other with a a carbon rig. The carbon rig was able to carry the larger headsails much further into higher wind ranges. The other had to shorten sail. I think I remember the carbon rig eliminated something like 100 lbs aloft. It was a hefty price. I believe Hall Spars made that one. Selden Mast makes carbon rigs as well.

- This site uses cookies to help personalise content, tailor your experience and to keep you logged in if you register. By continuing to use this site, you are consenting to our use of cookies. Accept Learn more…

My Cruiser Life Magazine

Cutter Rigged Sailboats [GUIDE] Advantages, Sailing, Options & Features

Cutter rigs are often more prevalent in boating magazines and theory than they are in your marina. Most cruising sailboats are Bermuda rigged sloops with just one permanently attached headsail. So, are two headsails better than one? Or, are they double the trouble?

Table of Contents

- History of Cutters

What is a Cutter Rig?

Cutter features, cutter rig options, sailing a cutter rigged sailboat, 5 popular manufacturers making cutter rigs, it takes two to tango, cutter rigged sailboat faqs.

History of Cutters

Cutters became popular in the early 18th century. These traditional cutters were decked (instead of open) and featured multiple headsails. Smugglers used cutters to smuggle goods, and the coast guard used cutters to try to catch the smugglers.

Various navies also used the cutter rig. Navy cutters featured excellent maneuverability and were better at sailing to windward than square-rigged ships.

Navies used cutters for coastal patrol, collecting customs duties, and “cutting out” raids. These “cutting out” operations consisted of a boarding attack. Fast, maneuverable cutters could stealthily approach an enemy vessel and board it. This type of attack was common in the late 18th century.

US Coast Guard ships, now powerful, fast, engine-driven, steel vessels, are still called cutters today as a nod to their past.

A cutter rig sailboat has two headsails instead of just one. The jib is located forward and is either attached to a bowsprit or the bow. The inner sail is called the staysail and is attached to an inner forestay.

Traditional cutters were built for speed. Today, cutter rigged sailboats are popular with ocean-crossing sailors, cruisers, and sailors looking for an easy to manage, versatile rig for all conditions.

It’s important to distinguish cutters from other types of boats with a single mast. Cutters regularly fly two headsails on nearly every point of sail. Many sloops are equipped to fly different-sized headsails, but it is unusual or unnecessary for them to fly more than one at a time.

Solent Rig vs Cutter Rig

A solent rig is traditionally called a slutter–a little bit sloop and a little bit cutter. This configuration features two large headsails mounted close together. The solent rig is good if you do a lot of downwind sailing. You can pole out both headsails and go wing-on-wing, with one headsail on the starboard side and one on the port side.

If you are on any other point of sail, you can only use one solent rig headsail at a time. If you use the inner sail, the wind flow is disrupted by the furled forward sail. And, if you use the forward sail, you’ll have to furl it to tack because there’s not enough space between the forestays.

The solent rig is a way to add more sail options to a standard sloop. Most solent stays are not required rigging to keep the mast up, so owners remove them when not in use to make tacking the primary headsail easier.

Advantages of a Cutter Rig

There are a lot of reasons to like a cutter. A cutter rigged boat has redundant rigging and spreads the sail load across its rigging. And a cutter rig offers increased sail options–it offers increased sail area in light winds and easy and efficient ways to decrease sail area in heavy weather.

In heavy weather, a cutter will drop or furl her larger headsail – usually a yankee or a genoa. That leaves just the smaller inner staysail. This arrangement is superior to the standard sloop, which sails in high winds by reefing her headsail. The staysail, however, lowers the center of effort on the sail plan and maintains draft over the reefed mainsail. That makes the boat more stable, maintains performance, and reduces stresses on the rig.

If you imagine the sailor going to sea and needing to reef, it’s easy to see how many more choices they have than the sloop sailor. While each sailor can reef their mainsail, a cutter skipper has full control over both headsails as well.

Because a cutter rig spreads the load across two headsails, it’s easier to manage. There might be more sails, but each sail is smaller and has smaller loads on it. That makes cutters the preferred option for sailing offshore when short-handed, as are more cruising couples.

Lastly, it has to be added that there’s something appealing about the traditional looks of a cutter.

Disadvantages of a Cutter Rig

While there are many benefits of a cutter, there are drawbacks and disadvantages too.

Sailors will have more lines to manage and more processes to think through. More sails mean more halyards and sheets. And when it comes to maintenance and upkeep, a cutter will have more standing and running rigging to replace, along with one more sail.

Cutters are also harder to tack. You’ll be dealing with two headsails instead of just one. Many designs deal with this problem by making the staysail self-tacking. This has fallen out of favor, but it’s a great advantage if you find yourself short-tacking up or down rivers.

Regardless of whether you need to tack both headsails or not, getting the larger sail to tack through the slot and around the inner forestay is sometimes a challenge. Many skippers find themselves furling the headsail, at least partially, to complete the tack.

Cutters need extra foretriangle room, which can mean adding a bowsprit, moving the mast back, or both.

Cutter Rig Position

Looking at a cutter rigged sailboat diagram, you might see a bowsprit depicted. Often, cutters fly their yankee from a bowsprit. Bowsprits allow boat designers to increase the fore triangle’s size without making the mast taller. Other cutters don’t use a bowsprit and mount the yankee sail on the bow.

A cutter sailboat might seem like more work. After all, there are two sails to trim and manage. In addition, you’ll have to perform maintenance on two sails and purchase and maintain double the hardware.

However, the two headsail arrangement can be easier to manage when the sails are under load. Instead of having one jib or genoa to trim, the weight and pressure are spread across two sails.

Mast Location

Today’s modern boat designers often focus on providing living space in the cabin. Designers often move the mast forward to create a larger, more open saloon. When the mast is forward, there’s less space to mount two headsails. A cutter sailboat needs a decent foretriangle area.